The metal fabrication and job shop industry is rapidly evolving due to increasing demand for customized products, shorter lead times, and greater precision. A business must streamline operations, improve visibility across departments, and minimize manual inefficiencies to stay competitive. That is where Odoo ERP software comes in.

The Odoo ERP system offers an all-in-one, fully integrated platform that connects every aspect of the fabrication business, including quoting, scheduling, production tracking, inventory, quality control, and accounting. Implementing an Odoo ERP enables you to automate repetitive processes, reduce errors, and make data-driven decisions that enhance productivity and profitability.

This blog explores why more metal fabricators and job shops are turning to Odoo ERP and how it simplifies their operations.

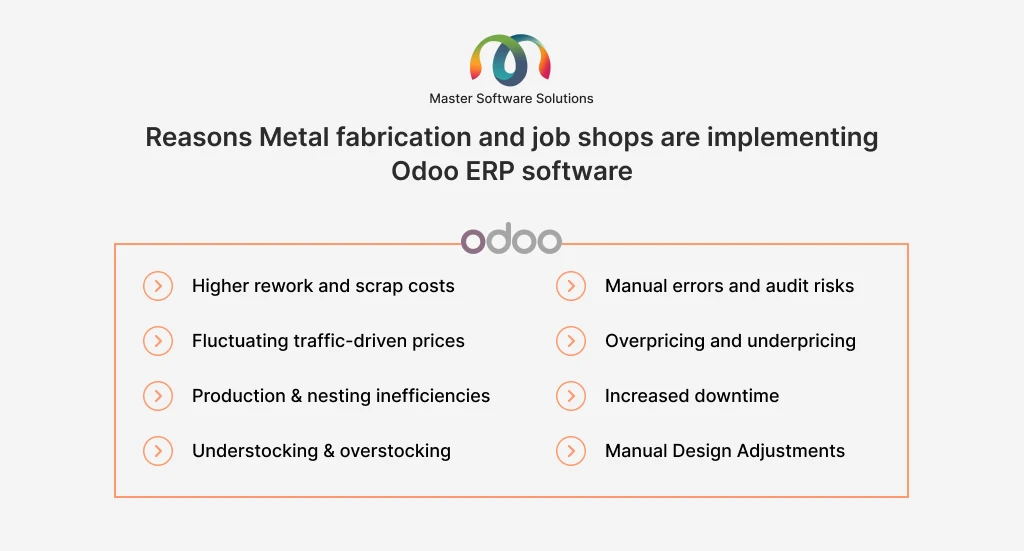

Reasons why metal fabrication and job shops are implementing Odoo ERP software

For many metal fabrication and job shops, daily operations can feel like a balancing act. Quoting, purchasing materials, scheduling production, and managing deliveries all need to run in sync manually or through a disconnected system. Relying on such systems or tools creates data silos, errors, and delays that impact productivity and profitability. Here are the reasons why many metal fabricators and job shop businesses are implementing an integrated system:

Higher rework and scrap costs

When metal fabrication and job shops manage batches and sub-batches manually using spreadsheets, paper-based records, or isolated systems, it becomes difficult to maintain traceability and control over the material throughout the production cycle.

Without a digital tracking system, it is challenging to trace which batch of raw material was used for which job and pinpoint where a defect originated. If a defect is detected at a later stage, the lack of visibility means fabricators often have to inspect or rework multiple items rather than addressing the specific faulty batch. This leads to wasted time, excess material use, and higher operational costs.

Over time, these inefficiencies not only increase scrap and rework expenses but also affect production reliability and customer satisfaction.

The key KPIs impacted are:

- Material Yield Rate: Drops due to poor tracking of raw material utilization and increased scrap.

- Rework & Scrap Percentage: Increases significantly because defects cannot be isolated to a specific batch or job.

- Production efficiency: Declines as operators spend more time identifying and correcting errors instead of completing new jobs.

- Defect Detection Rate: Becomes inconsistent, since manual systems often delay or miss the early identification of defective materials.

- Cost of Quality (CoQ): Rises due to higher rework, inspection, and water handling costs.

- Order Fulfillment Cycle Time: Lengthens due to rework, inspection, and waste handling costs.

- Customer Return or Complaint Rate: Increases when defective products reach customers due to missed defects.

- Overall Equipment Effectiveness (OEE): Decreases due to unplanned rework and downtime disrupting production flow.

Manual errors and audit risks

In metal fabrication and job shop operations, heat numbers and Mill Test Reports (MTRs) are crucial, ensuring material authenticity, quality assurance, and compliance with industry standards. Each heat number uniquely identifies a batch of metal, while MTRs verify its chemical and mechanical properties.

When these records are captured, linked, and carried through production manually using spreadsheets, paper trails, or separate systems, errors and inconsistencies are inevitable. Misfiled or lost MTRs make it difficult to trace materials used in a particular part or order, especially when jobs involve multiple materials or subcontracted processes.

This loss of traceability not only disrupts production tracking but also leads to compliance risks during customer audits or regulatory inspections. Without verifiable documentation, shops may face rejected orders, rework requirements, or even financial penalties. Additionally, the inability to provide proof of material authenticity can damage customer trust and long-term business relationships.

Key KPIs impacted are:

- Traceability Accuracy: Declines when the heat numbers and MTRs are not properly linked to the corresponding materials and finished products.

- Compliance Rate: Drops as incomplete or missing documentation leads to audit nonconformance.

- Quality Assurance Turnaround Time: Increases because staff must manually locate and verify documents for each part or order.

- Rework and Scrap Rate: Rises when materials with missing or mismatched MTRs must be processed or discarded.

- Audit Readiness Score: Falls due to the inability to produce accurate traceability records.

- Customer Satisfaction Index: Declines when the clients lose confidence in the manufacturer’s ability to maintain quality and compliance documentation.

- Operational Efficiency: Reduces as manual data entry and document retrieval consume valuable production time.

Fluctuating traffic-driven prices

In the metal fabrication sector, import tariffs, tariff changes, and global market volatility all significantly impact the cost of raw materials. These fluctuations force businesses to frequently update pricing across multiple items, assemblies, and customer quotes.

When bulk repricing is handled manually using spreadsheets or disconnected tools, the process becomes slow, error-prone, and difficult to control. Even minor errors can lead to incorrect quotes, misaligned invoices, or out-of-date product pricing, all of which have a direct impact on profitability and compliance.

For instance, a missed tariff update may lead to undercharging customers, while overpricing can make quotes uncompetitive. Inaccurate cost adjustments also complicate financial reporting and margin analysis, while mismatched invoices increase the likelihood of customer disputes and lost trust. Over time, these inefficiencies can erode margins, create compliance challenges, and damage long-term customer relationships.

Key KPIs impacted are:

- Gross Profit Margin: Shrinks due to inaccurate or delayed pricing adjustments.

- Revenue Leakage Rate: Increases when quotes or invoices don’t reflect updated material costs.

- Quote Accuracy Percentages: Drops when price differences between quotes and invoices are caused by manual entry errors.

- Invoice Dispute Rate: Rises when customers identify inconsistencies in billing versus agreed pricing.

- Price Update Turnaround Time: Lengthens due to manual recalculations and approvals across product lists.

- Compliance Accuracy: Falls when tariff-related pricing changes are not applied consistently across all products and customers.

- Customer Retention Rate: Drops when repeated pricing disputes reduce trust and satisfaction.

Overpricing and underpricing

Accurate job costing is essential for profitability in metal fabrication and job shop operations. However, when material usage, nesting efficiency, and machine time are calculated manually, estimations often rely on assumptions rather than precise data. Without real-time visibility into machine performance, material yields, and process efficiency, quotes can easily become inaccurate.

Manual estimation frequently results in two costly outcomes:

- Underpricing: When hidden material waste, setup time, or machine inefficiencies go unaccounted for, the shop absorbs unexpected costs and loses profits.

- Overpricing: Inflated estimates make quotes uncompetitive, leading potential customers to choose other vendors.

Over time, these inconsistencies distort true cost insights, disrupt margin planning, and damage a company’s reputation for reliability and transparency.

Key KPIs impacted are:

- Quote Accuracy Rate: Declines due to inconsistent estimation of material and labor costs.

- Gross Profit Margin: Becomes unpredictable when actual production costs differ from quoted prices.

- Win Rate (Quote-to-Order Conversion): Drops as inaccurate or high-priced quotes deter customers.

- Cost Variance: Increases because estimated job costs often deviate from actual costs.

- Material Utilization Efficiency: Falls when poor nesting or inaccurate material estimation leads to waste.

- Machine Utilization Rate: Becomes difficult to track, leading to unused or overburdened equipment.

- Customer Satisfaction Index: Declines due to inconsistent pricing or missed delivery commitments, leading to poor planning.

Production & nesting inefficiencies

In metal fabrication and job shop environments, precision and speed are critical. When design files (CAD/CAM drawings or nesting programs) are transferred to machines manually through USB drives, emails, or shared folders, it introduces delays and errors at multiple stages of production.

Manually handling files increases the risk of using outdated or incorrect versions, missing parameters, or incomplete design details. Operators may unknowingly load the wrong file, leading to poor nesting efficiency, wasted raw material, and misaligned cuts of bends. Additionally, manual transfers slow down change management, as every design update requires manual re-entry or file replacement at each machine, which can disrupt workflow and cause rework.

These inefficiencies not only waste time and materials but also extend turnaround cycles, affect schedules, and reduce overall equipment effectiveness (OEE).

Key KPIs impacted are:

- Production Throughput: Decreases as the machines sit idle during file transfers or corrections.

- Rework and Scrap Rate: Increases when incorrect or incomplete files result in material waste.

- First-pass Yield (FPY): Drops because more jobs require corrections due to setup or nesting errors.

- Material Utilization Efficiency: Declines when nesting layouts aren’t optimized due to outdated files.

- Overall Equipment Effectiveness (OEE): Falls as setup and correction time increase.

- Order Lead Time: Increases due to manual file management, which delays production start times.

- On-time Delivery Rate: Declines when production errors or rework push back delivery schedules.

Increased downtime

In the metal fabrication or job shop environment, real-time visibility into production activities and machine performance is critical for maintaining efficiency. However, when production tracking is done manually through paper logs, spreadsheets, or verbal reporting, it becomes prone to errors, omissions, and delays in data entry.

Managers cannot accurately monitor operator efficiency and machine utilization without automated tracking, leading to increased downtime. Breakdowns, idle times, or delays often go unnoticed until production disruption occurs, making it impossible to respond proactively. This reactive approach results in prolonged downtime, missed delivery commitments, and higher maintenance costs.

Moreover, inconsistent or incomplete production data makes it harder to analyze performance trends or identify underutilized assets. Over time, these inefficiencies reduce throughput, limit capacity planning, and impact overall profitability.

Key KPIs impacted are:

- Machine Utilization Rates: Declines due to untracked idle time and inefficient scheduling.

- Downtime Percentage: Increases as issues remain unresolved until they are resolved or until they escalate.

- Overall Equipment Effectiveness (OEE): Falls as availability and performance metrics differ.

- Production Throughput: Decreases because bottlenecks and delays are not detected in time.

- On-time Delivery Rate: Drops when unmonitored downtime causes missed deadlines.

- Mean Time to Repair (MTTR): Increases since maintenance teams respond later to breakdowns.

- Operator Productivity: Declines due to a lack of visibility into individual or shift-level performance.

Understocking & overstocking

In metal fabrication and job shop operations, manually managing inventory levels and procurement cycles using spreadsheets or isolated systems results in significant inefficiencies. Without real-time data on material consumption, purchase orders, or reorder points, teams often struggle to maintain the right stock balance.

This lack of visibility frequently results in understocking (causing production delays when materials run out) or overstocking (tying up capital in unused inventory). Inaccurate manual entries, delayed purchase updates, or poor demand forecasting only worsen the issue. Such inconsistencies lead to missed deadlines, disrupted production schedules, and ultimately, a poor customer experience.

Moreover, without a centralized system, coordination between procurement, inventory, and production departments becomes fragmented, leading to duplicated orders, vendor delays, and costly last-minute purchases.

Key KPIs impacted are:

- Inventory Turnover Ratio: Declines when excess stock accumulates due to poor planning.

- Stockout Rate: Increases when materials aren’t replenished on time.

- Carrying Costs of Inventory: Rise as surplus inventory occupies storage space and capital.

- Procurement Lead Time: Lengthens because purchase requests and approvals are managed manually.

- Production Downtime: Increases when materials are unavailable for scheduled jobs.

- Order fulfillment Rate: Drops due to missed delivery deadlines caused by material shortages.

- Customer Satisfaction Score (CSAT): Declines when late deliveries or incomplete orders affect service quality.

- Working Capital Efficiency: Decreases when funds are locked in non-moving stock.

Manual Design Adjustments

In metal fabrication and job shop environments, customer requirements and design specifications can change at any stage of production. However, in a traditional setup without ERP integration, making real-time design modifications during an ongoing manufacturing process is nearly impossible.

When design updates or corrections are needed, whether due to a customer’s last-minute change or an operator’s discovery of an error, the process becomes manual and disruptive. Production must stop, design files must be manually revised, and machines must be reset or reprogrammed. This downtime leads to scrapped materials, lost productivity, and increased operating costs.

Without a system that synchronized design revisions with production data, even small adjustments can create inconsistencies between what was designed, scheduled, and actually produced. These disconnects can also impact delivery timelines and customer satisfaction, especially in made-to-order operations where precision and agility are critical.

The KPIs impacted are:

- Scrap and Rework Rate: Increases due to discarded partially processed materials.

- Production Downtime: Rises as jobs are paused to update or reload design files manually.

- Change Order Response Time: Lengthens because revisions aren’t seamlessly communicated to production.

- Machine Utilization Rate: Drops as equipment sits idle during reconfiguration or manual updates.

- Order Lead Time: Extended due to delays in reprocessing and reprogramming.

- Material Yield Rate: Decreases because partial assets or components are wasted.

- On-time Delivery Rate: Declines when production restarts push back delivery schedules.

- Customer Satisfaction Index: falls when changes cannot be accommodated quickly or cost-effectively.

Bottom-line

For metal fabrication and job shop businesses, operational efficiency, precision, and agility are essential to stay competitive in a demanding market. Managing complex processes, such as production scheduling, material tracking, pricing updates, and design revisions, requires an integrated system. This can result in inefficiencies, rising costs, and missed deadlines.

Implementing an Odoo ERP system allows you to integrate all of these business processes and manage them from a single system. If you are a metal fabrication business and want to implement Odoo ERP, contact us.

Master Software Solutions is an official Odoo partner that provides end-to-end Odoo services, including consulting, implementation, development, migration, and ongoing support. We can help you transition from your previous system to the new Odoo ERP system.