Manufacturing businesses rely on efficiency, accuracy, and data-driven decision-making to compete in this dynamic landscape. As production lines grow more complex and customer expectations rise, manufacturing businesses need an integrated solution to manage everything from inventory and procurement to production planning and quality control. This is where Odoo ERP stands out.

Odoo’s modular, flexible, and cost-effective platform enables manufacturers to streamline operations, enhance visibility, and automate key business processes in a single system. However, implementing an Odoo ERP can be daunting without a clear roadmap.

This blog covers the entire process of implementing Odoo ERP for your manufacturing business, from planning and customization to training and post-deployment optimization.

Table of Contents

Understanding Odoo ERP for manufacturing

Odoo ERP (Enterprise Resource Planning) is an all-in-one business management software that helps organizations streamline and automate their operations. For manufacturing businesses, Odoo offers a comprehensive suite of integrated applications designed to manage the entire production lifecycle, from raw material procurement to finished delivery.

At its core, Odoo ERP brings all departments together under a single platform, ensuring real-time visibility and seamless communication between teams. This eliminates the need for multiple disconnected tools and manual data entry, reducing errors and improving productivity.

Essential Odoo ERP modules for the manufacturing industry

Implementing Odoo ERP in a manufacturing environment is most effective when the right combination of modules is used. Each module plays a critical role in streamlining operations, enhancing visibility, and driving efficiency across departments. Below are the essential

Odoo ERP modules for every manufacturing company to consider.

Manufacturing (MRP)

It manages bills of materials (BOMs), work orders, routings, and production scheduling. Real-time tracking of manufacturing orders ensures a smooth, efficient, and waste-free production.

Inventory management

This module supports multi-warehouse management, real-time tracking, batch and lot control, and barcode integration for raw materials, semi-finished goods, and finished products. This helps manufacturers reduce inventory costs and prevent stockouts or overstocking.

Purchase management

The purchase module automates the procurement process from supplier quotations to purchase orders and vendor management. When integrated with inventory and manufacturing, it ensures timely material availability depending on your production needs and reorder rules.

Sales management & CRM

Odoo’s sales and CRM modules help align production planning with customer demand. The manufacturer can forecast orders, track sales performance, and ensure that production aligns with confirmed and expected sales.

Quality management

The quality module allows you to define inspection points, quality control checks, and non-conformance reports (NCRs) at various stages, including procurement, production, and delivery.

Maintenance

This module focuses on preventive and corrective maintenance of machinery and equipment. It can automatically schedule maintenance and track performance, enabling businesses to minimize downtime and extend equipment lifespan.

Accounting and finance

Integrated accounting provides real-time visibility into production costs, inventory valuation, and profitability analysis. Automated journal entries, expense tracking, and cost control tools make financial management easier and more transparent.

Benefits of Odoo ERP for manufacturing businesses

Implementing Odoo ERP can transform the way manufacturing companies operate by integrating every aspect of the business into a single, intelligent platform. Here are the key benefits of Odoo ERP for the manufacturing industry.

Streamlined operations

The centralized Odoo ERP system eliminates redundant data entry and manual coordination, ensuring smooth and synchronized operations across the entire production chain.

Real-time visibility and control

Monitoring production status, tracking inventory levels, and analyzing performance metrics enables faster decision-making and immediate response to production issues or supply chain disruptions.

Improved production planning & scheduling

Odoo’s manufacturing module allows precise production scheduling, work order management, and resource allocation to reduce bottlenecks and optimize equipment utilization.

Enhanced quality control

Integrated quality management ensures multiple quality checkpoints, conducts automated inspection, and tracks non-conformities to maintain consistency and reduce rework or waste.

Reduced operations costs

Automation and better planning with Odoo minimize inefficiencies that lead to waste, overtime, or overproduction, and help lower overall operational costs.

Better inventory and supply chain management

Accurate, real-time insights into inventory levels and supplier performance ensure materials are always available when needed, reducing downtime and delays.

Data-driven decision-making

Odoo’s powerful analytics and reporting tools give management a clear picture of business performance, from production efficiency to profitability. This empowers leaders to make strategic, evidence-based decisions that drive growth.

Odoo ERP implementation challenges in manufacturing

While Odoo ERP offers powerful tools to streamline manufacturing operations, implementing it successfully requires careful planning, coordination, and change management. Manufacturing environments are often complex, and businesses face specific challenges during implementation.

Complex business processes and customization needs

Manufacturing companies often have unique workflows, production methods, and reporting requirements. These procedures might not be compatible with standard Odoo modules right out of the box, necessitating module configuration and customization.

Solution

Conduct a thorough process analysis before implementation. Work with experienced Odoo consultants like us to tailor the system while maintaining scalability and avoiding unnecessary custom code.

Data migration difficulties

Migrating data from legacy systems, such as spreadsheets or outdated software, can be time-consuming and error-prone. Inaccurate or incomplete data migration can lead to reporting errors, production delays, or compliance issues.

Solution

Clean and validate data before migration. Create a structured migration plan and test data integrity thoroughly in a staging environment before going live.

User resistance and lack of training

Employees accustomed to old systems may resist change, especially if the new ERP interface is complex. Without proper training, adoption rates can drop, leading to inefficiencies and frustration.

Solution

Involve end-users early in the implementation process and provide hands-on training sessions and user manuals. Demonstrating how Odoo simplifies daily tasks can boost acceptance and confidence.

Integration with existing systems

Manufacturers often use specialized software for areas such as machine monitoring, CAD, or PLC systems. Integrating Odoo with these tools can be technically challenging and may require third-party connectors or custom APIs.

Solution

Identify integration needs during the planning phase. Use Odoo’s API capabilities and work with technical experts to ensure smooth, real-time data exchange between systems.

Inadequate change management and project oversight

ERP implementation is not just a technical project but is a strategic organizational change. Without clear leadership, communication, and project management, timelines can slip, and system adoption can falter.

Solution

Assign a dedicated implementation team with defined roles and responsibilities. Establish milestones, regular progress reviews, and feedback loops to keep the project aligned with business goals.

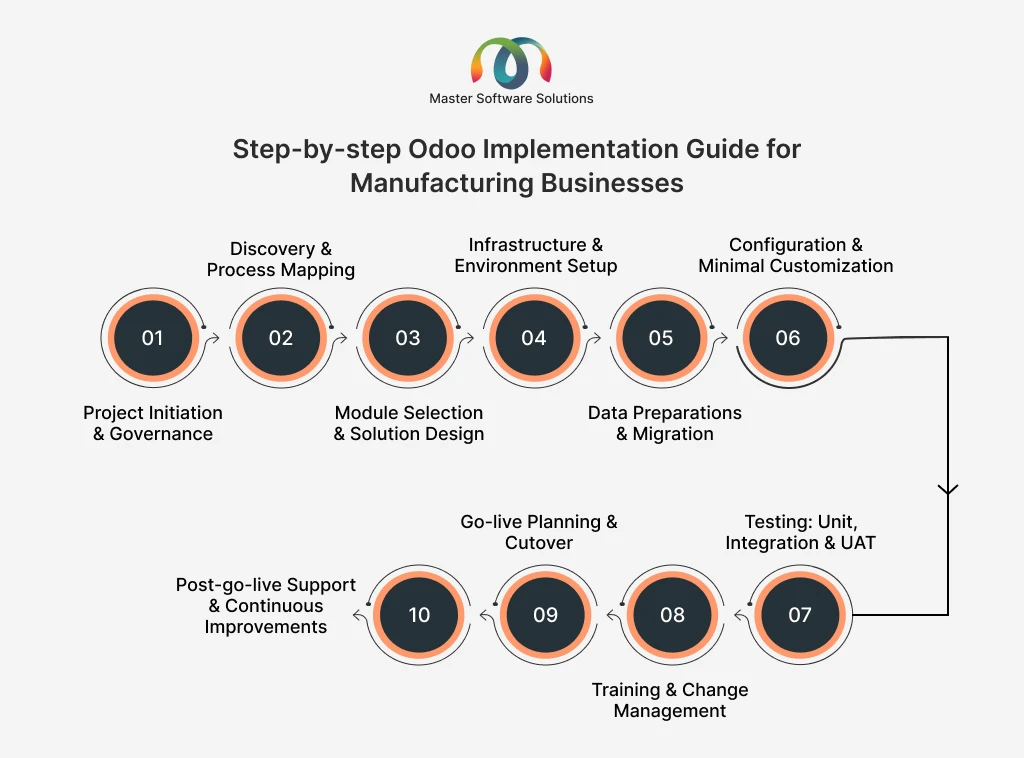

Step-by-step Odoo implementation guide for manufacturing businesses

Below is a practical, actionable implementation roadmap you can drop into your project plan. Here is what to do, who should own it, deliverables/checklists, common pitfalls, and mitigation, so nothing important gets missed.

Project initiation & governance

Goal: Set up leadership, scope, and success criteria.

Actions:

- Appoint a project sponsor (executive), project manager, and functional leads (manufacturing, inventory, purchasing, quality, IT, and finance).

- Define project scope (modules, factories/sites, languages, and currencies).

- Establish governance (steering committee, weekly cadence, and escalation path).

- Define success metrics/KPIs (e.g., production on-time %, inventory turns, order lead time, data accuracy).

Deliverables/checklist

- Project charter (scope, objectives, and stakeholders).

- RACI matrix.

- KPI definitions and reporting owner.

Pitfalls & mitigation

Too-broad scope: use phased rollouts (MVP first)

Weak sponsorship: secure executive time commitment up front.

Discovery & process mapping

Goal: Capture existing processes and requirements; identify gaps.

Actions:

- Map end-to-end manufacturing processes: procurement -> incoming QC -> MRP/BOM -> routing -> work orders -> QC -> shipping -> invoicing

- Document exceptions and special processes (make-to-order, configure-to-order, co-packaging, and subcontracting).

- Capture non-functional requirements: uptime, integrations, regulations, traceability, and lot/batch needs.

Deliverables/checklist

- As-is process maps and pain points.

- To-be process maps aligned to Odoo capabilities.

- Requirements traceability matrix.

Pitfalls & mitigation

- Skipping frontline input: workshops with floor supervisors/operators.

- Unclear requirements: validate with real transactions/examples.

Module selection & solution design

Goal: Choose standard Odoo modules and design solutions for requirements.

Actions:

- Pick core modules: Manufacturing (MRP), Inventory, Purchase, Sales/CRM, Quality, Maintenance, and Accounting. Add project, PLM, or IoT where needed.

- Design data model: Warehouses, locations, routes, BOM structure, routing steps, work centers, shifts, and cost methods.

- Design integrations: PLC/SCADA, machine data, e-commerce, EDI, barcode systems, CAD/PLM, payroll.

Deliverable/checklist

- Functional design document (FDD)

- Integration matrix (system, data exchanged, frequency, and owner).

- Security & access plan (roles/permissions).

Pitfalls and mitigation

Over-customizing instead of configuring: prefer standard Odoo features and document justified customizations.

Infrastructure & environment setup

Goal: Prepare environments and infrastructure for development, testing, and production.

Actions:

- Provision environments: development, staging (UAT), and production.

- Decide on Hosting: Odoo Online vs. Odoo.sh vs. self-hosted (cloud/VPS) and configure backups and monitoring.

- Configure basic system settings: companies, currencies, units of measure, sequences, and users.

Deliverables/checklists

- Environment access matrix and credentials (secure store).

- Backup & restore plan.

- Performance monitoring plan.

Pitfalls & mitigation

Insufficient test environment parity -> mirror production settings where possible.

Data preparations & migration

Goal: Clean, map, and migrate master and transactional data safely.

Actions:

- Identify data to migrate: products (with variants and attributes), BOMs, routings, suppliers, customers, inventory balances (by lot/batch), open POs/SOs, work orders, and charts of accounts.

- Clean and standardize data (SKUs, units, naming)

- Create migration mapping (source field -> Odoo field) and transformation rules.

- Test migrations to staging: validate with stakeholders.

Deliverables/checklist

- Migrating the mapping spreadsheet.

- Data quality report.

- Reconciliation templates for opening balances.

Pitfalls & mitigation

- Migrating garbage data: enforce cleansing rules and have sign-offs on migrating samples.

- Missing lot/batch history needs: determine retention vs. snapshot strategy.

Configuration & minimal customization

Goal: Configure Odoo and implement only required customizations.

Actions:

- Configure MRP: BOM types, routings, work centers, operation durations, and production order rules.

- Configure inventory: routes (make-to-stock and make-to-order), barcode rules, and serial/lot tracking.

- Configure quality & maintenance workflows and alerts.

- Implement integrations and lightweight custom modules only when necessary. Keep custom code isolated and documented.

Deliverables/checklist

- Configuration checklist per module.

- Customization document (purpose, owner, tests, and upgrade plan).

- API/integration endpoints documentation.

Pitfalls & mitigation

- Feature creep via customizations: gate custom features through an impact review.

- Testing: unit, integration & UAT

Goal: Validate system behavior broadly and with end users.

Actions:

- Unit test configurations and custom modules.

- Integration tests for data flows (E.g., PO -> inventory -> MRP).

- Prepare UAT scenarios using real business cases (normal and exception flows).

- Execute UAT with end users; log and prioritize defects.

Deliverables/checklist

- Test script & acceptance criteria.

- Defect log with priorities and owners.

- UATs sign off on documents.

Pitfall & mitigation

- Insufficient realistic testing: use actual orders/BOMs and simulate peak loads.

Training & change management

Goal: Ensure users know how to use the system and adopt new processes.

Actions:

- Run role-based training sessions (shop floor, planners, purchasers, QC, and Finance).

- Provide quick-reference guides and on-screen help for common tasks such as creating work orders, validating production, and counting inventory.

- Run a pilot with a small team/site to refine training and procedures.

Deliverables/checklist

- Training materials and recordings.

- Super-user list and escalation paths.

- Change the impact communication plan.

Pitfalls & mitigations

Too little hands-on training: emphasize workshops and showing, not just slide decks.

Go-live planning & cutover

Goal: Move from old systems to Odoo with minimal operational disruptions.

Actions:

- Describe the big-bang versus phased cutover strategy (by plant, product line, or module).

- Freeze period for transactional data before cutover (define what is frozen).

- Execute the final data load, reconcile opening balances and inventory, and validate critical transactions.

- Have a rollback plan and on-call support.

Deliverable/checklist

- Cutover runbooks (detailed step-by-step activities and owners).

- Verify important transactions and complete the reconciliation of opening balances and inventory.

- Have a rollback plan and on-call support.

Deliverables/checklist

- Cutover runbook (detailed step-by-step activities and owners).

- Final reconciliation checklist.

- Emergency rollback instructions.

Pitfalls & mitigation

Rushed cutover: have a dry run and a clear freeze window; ensure staff coverage for critical days.

Post-go-live support & continuous improvements

Goal: Stabilize operations, measure success, and iterate improvements.

Actions:

- Provide hypercare support with super-users and vendor/partner on-call.

- Monitor KPIs and user feedback; prioritize quick wins and backlog items.

- Plan enhancements (additional modules, deeper integrations, & automation).

- Establish a governance model for change requests and upgrades.

Deliverables/checklists

- Hypercare support roster and SLA.

- Post-launch review report and improvement roadmap.

- Upgrade and maintenance schedule.

Pitfall & mitigation

- Assuming “done” at go-live: maintain a prioritized backlog and a continuous improvement cadence.

Master Software Solutions: Odoo consulting services for the manufacturing industry

Implementing Odoo ERP in a manufacturing environment requires deep industry knowledge, precise configuration, and experienced guidance. That is where Master Software Solutions (MSS) comes in. As a trusted Odoo consulting and implementation partner, we help manufacturing businesses leverage Odoo to streamline operations and achieve digital transformation.

Our expertise in Odoo for manufacturing

Master Software Solutions has a proven track record of delivering tailored Odoo ERP solutions designed specifically for manufacturing companies of all sizes, from small workshops to large-scale production plants. Our team of certified Odoo consultants, developers, and business analysts understands the complexities of modern manufacturing processes and delivers efficiency, quality, and profitability. Our Odoo Consulting Services Include:

- Business Process Analysis & ERP Strategy: We assess your current workflows, identify inefficiencies, and create a roadmap for successful Odoo adoption.

- Odoo Implementation & Customization: From core MRP and Inventory modules to advanced integrations, we tailor Odoo to match your exact manufacturing requirements.

- Data Migration & Integration: Seamless migration from legacy systems and integration with third-party tools such as PLC, IoT, and MES platforms.

- Training & User Adoption: Comprehensive training programs ensure your team is confident and efficient using Odoo’s modules and workflows.

- Support & Continuous Improvement: Post-implementation support, version upgrades, and optimization to ensure long-term value and scalability.

Master Software Solutions is an official Odoo partner that can help you transform your manufacturing operations into a seamless, data-driven ecosystem. We help you unlock efficiency, reduce costs, and stay competitive in an evolving market, from production planning to quality assurance. Are you ready to optimize your manufacturing with Odoo ERP? Contact us today to schedule a free consultation with our Odoo expert.