The dairy supply chain is one of the most complex supply chains, and a small hiccup can significantly impact yield. Manually managing your business operations increases the likelihood of errors, leading to higher losses. This is where an ERP system comes in. This blog focuses on the Odoo ERP platform and explores how it helps dairy manufacturing businesses.

What is Odoo for dairy manufacturing? – Odoo for dairy manufacturing businesses is a customized enterprise resource planning software specifically designed to manage dairy business operations, including production, sales, finance, inventory, CRM, quality control, supply chain management, distribution, and business intelligence.

Table of Contents

Three major challenges faced by dairy manufacturing businesses

There are three critical challenges faced in dairy manufacturing businesses that can reduce your overall efficiency, yield, and profits while increasing the costs. Here are the three challenges dairy manufacturing businesses face.

Supply chain management issues

In the dairy industry, supply chain challenges are complex due to the nature of the primary raw material: raw milk.

- Perishability and time sensitivity – Raw milk is highly perishable and must be collected, chilled, and processed in a timely manner. Delays in collection or transport directly impact quality and lead to immediate spoilage. This is one of the major challenges, as it demands an exceptionally reliable and time-bound logistics network.

- Quality variation and testing – Milk quality (fat, SNF, adulteration, and water content) varies based on the source, feed, and season. The milk collection source can be individual farmers or cooperatives. It is important to include real-time quality testing at every collection point, as the farmers or cooperatives are paid accordingly. The quality at the collecting points determines the product quality of the final yield.

- Seasonal fluctuations – Milk supply is not consistent. It may increase or decrease in certain seasons. Dairy manufacturers must adjust production schedules and storage capacity to handle this unpredictability.

Inefficient inventory management

Dairy products have a short shelf life, making traditional inventory models ineffective and posing significant financial risks.

- Short shelf life & spoilage risks – Dairy products, especially fresh items like fluid milk, yogurt, and paneer, have one of the shortest shelf lives in the food industry. Inefficient management directly results in losses due to spoilage, waste, and markdowns.

- Need for batch and expiry tracking – Unlike durable goods, every batch (lot) of dairy product must be tracked with a precise expiry date. Businesses must strictly implement a First-Expiry, First-Out (FEFO) inventory strategy to ensure older stock is sold first. Failure to do so can result in unsafe products reaching consumers or ending up as waste.

- Cold chain management – Dairy products require continuous, unbroken refrigeration (cold chain). Inventory management isn’t just about counting units; it is about monitoring the temperature of storage and transport units. Any disruption in the cold chain leaves the inventory unusable, resulting in financial losses.

- SKU complexity – A typical dairy processes one raw material (milk) into multiple Stock Keeping Units (SKUs), such as different fat-content milk variants, various cheeses, flavored yogurts, butter, and others. Managing production, packaging, and finished goods for this diverse product line adds significant complexity.

Strict safety and quality regulations

The dairy industry is one of the most heavily regulated sectors due to the health risks associated with microbial contamination and adulteration.

- Public health risks – Contaminated or improperly processed dairy products can lead to severe foodborne illnesses. This makes regulatory compliance non-negotiable and requires exhaustive documentation.

- Mandatory testing and documentation – Regulatory bodies (FSSAI in India, FDA in the US, or EFSA in Europe) require mandatory testing at various stages, from raw material arrival to final product packaging. This includes testing for pathogens, antibiotics, adulterants, and quality parameters. Manufacturers must maintain detailed records of these tests for every batch for years.

- Traceability – Regulators demand end-to-end traceability. If a contamination occurs, the manufacturer must be able to identify the specific collection route, processing batch, and distribution channel of the affected product. This requires robust, real-time data systems.

- Hygiene and sanitation standards – Processing plants must adhere to strict Good Manufacturing Practices (GMP) and maintain excellent sanitation. Monitoring and documenting cleaning cycles, equipment maintenance, and personnel hygiene are continuous regulatory requirements that demand sophisticated management systems and cultural compliance.

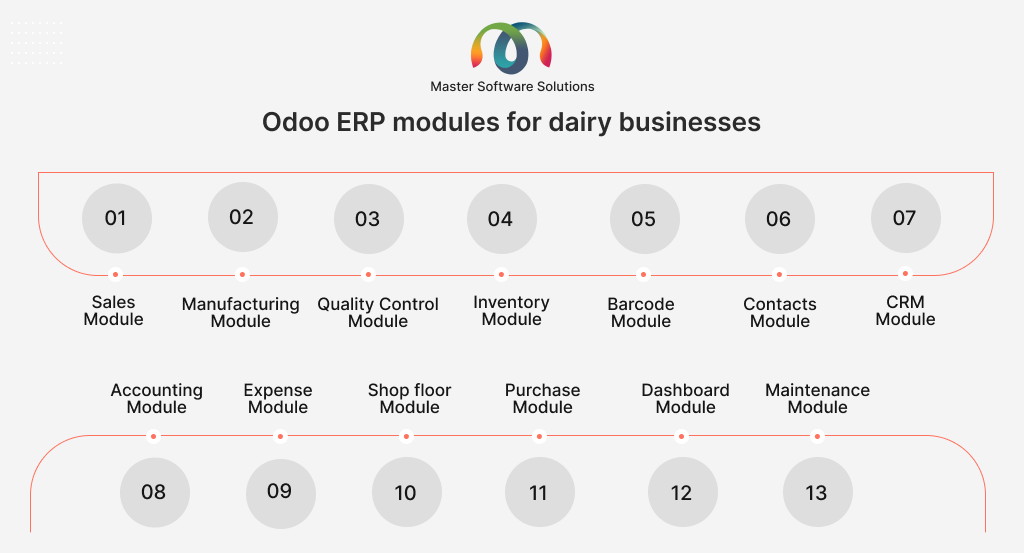

Odoo ERP modules for dairy businesses

The Odoo ERP system for dairy businesses provides all the essential modules that enable manufacturers to manage and track their end-to-end operations, improving yield. Master Software Solutions designed Odoo specifically for dairy manufacturing businesses. You can contact us if you are a dairy business seeking an enterprise-level solution. The Odoo ERP modules for the dairy industry are:

Sales module

The sales module helps dairy businesses manage orders from distributors, retailers, and direct customers. It streamlines quotation creation, order confirmation, pricing, and invoicing. You can track delivery status and customer payments, resulting in more efficient B2B and B2C transactions. For example, when a distributor orders 500 liters of milk or 100 boxes of cheese, the order is recorded and automatically linked with inventory and accounting.

Manufacturing module

The manufacturing module of Odoo ERP software manages the entire milk processing and production workflow, from pasteurization and homogenization to packaging dairy products like butter, yogurt, or cheese. It enables production planning, tracks raw material consumption, and ensures traceability from raw milk to finished goods. For example, you can define a Bill of Materials (BoM) for yogurt production, including milk, cultures, sugar, and packaging materials, and monitor batch production.

Quality control module

This module of Odoo dairy ERP ensures product consistency and compliance with the dairy industry regulations. It allows businesses to define and automate quality checkpoints during production, packaging, and dispatch. For example, you can set up quality tests for fat content, temperature checks, and microbial limits before releasing each batch.

Inventory module

The inventory module helps manage raw materials (such as raw milk, cultures, and flavoring), semi-finished goods, and finished products across multiple warehouses. It supports lot and batch tracking, FIFO/FEFO management, and automated stock replenishment. For example, when milk stock drops below a threshold, the system can automatically trigger a purchase order or production batch.

Also read: How Artificial Intelligence (AI) Is Helping The Dairy Industry?

Barcode module

The barcode module improves warehouse accuracy and efficiency by enabling scanning of products, raw materials, and lots during receipt, production, or delivery. For example, workers can scan a barcode to identify the milk batch, track movement, or validate deliveries without manual entry.

Contacts module

The contact module stores information about all stakeholders, including suppliers (the farmers and packaging vendors), distributors, retailers, and customers. It provides a centralized view of communication history and relationship details. For example, you can view a retailer’s full transaction history or a supplier’s contract details from one screen.

CRM (Customer Relationship Management) module

The CRM module helps manage leads, opportunities, and customer relationships. It enables the sales teams to follow up with distributors, supermarkets, or corporate clients efficiently. For example, track a lead from a new cafe chain interested in bulk milk supply, set reminders for follow-ups, and convert them into a customer.

Accounting module

The accounting module handles all financial transactions, including sales invoices, supplier bills, payroll, and taxes. It integrates with sales and purchase modules to automate accounting entries. For Example, when a sales order is confirmed and delivered, the corresponding invoice and payment record are automatically generated.

Expense module

The expense module allows dairy employees to record and get reimbursement for travel, logistics, or utility-related expenses. It helps the finance team to monitor operational costs efficiently. For example, a driver can submit fuel receipts from milk delivery trips for approval and reimbursement.

Shop floor module

This module gives real-time visibility of the production floor. Operators can log work orders, report progress, and track machine performance directly from tablets or terminals installed on the floor. For example, supervisors can monitor ongoing pasteurization or packaging batches in real time.

Purchase module

The purchase module automates procurement of raw milk, cultures, packaging materials, and cleaning chemicals. It streamlines vendor management, purchase orders, and supplier billing. For example, when milk supply runs low, the system can automatically create a purchase order to the local farmer cooperative.

Dashboard module

The dashboard module provides real-time business insights, including production status, stock levels, sales performance, and financial summaries in a visual format. For example, the system alerts you when a pasteurizer is due for maintenance, minimizing downtime and ensuring food safety compliance.

Maintenance module

The maintenance module ensures all dairy equipment (pasteurizers, chillers, and packaging lines) is regularly serviced, preventing breakdowns. It supports preventive and corrective maintenance scheduling. For example, the system alerts you when a pasteurizer is due for maintenance, minimizing downtime and ensuring food safety compliance.

Additional Odoo modules for efficient dairy manufacturing

Master Software Solutions has developed Odoo plugins to enhance Odoo’s functionalities. We have also integrated them with our custom Odoo ERP for dairy businesses. Here are the Odoo plugins.

Route optimization

You can plan and optimize your multi-stop delivery route to reduce turnaround time for your drivers. It also offers real-time driver tracking, enabling you to monitor the driver’s performance. The route optimization plugin can help you reduce last-mile delivery costs while improving efficiency and productivity.

B2B sales benchmarking tracking

This plugin is specifically for businesses with a B2B customer base that have predefined trading agreements, which include payment terms, delivery schedules, pricing structures, return policies, quality standards, order minimums/maximums, and service level agreements (SLA). B2B sales benchmarking tracking enables you to track and monitor defined benchmark sales from a specific customer.

B2B volume-based pricing

This plugin automatically adjusts the price slab predefined by you based on past sales. You can define a discounted price for your customer if the sales exceed the minimum quantity for the current month. You can define multiple prices for a single product. The B2B volume-based pricing automatically applies prices to the sales orders. The pricing is updated only concerning the current month’s order quantity status.

To explore other Odoo plugins by Master Software Solutions, CLICK HERE.

Implementing Odoo for dairy manufacturing business – Master Solution Solutions

Master Software Solutions is an IT service-based company that offers Odoo consulting services, including implementation, migration, module development, customization, integrations, and support and maintenance services. We have already customized the Odoo ERP system for dairy manufacturing business operations, making implementation easier and faster. Contact us to learn more about our dairy ERP system.