Running a dairy business from milk procurement and quality testing to production, packaging, inventory, and distribution requires precise management. This ensures freshness, safety, and profitability. Traditional methods or disconnected systems are insufficient for handling complex, fast-paced operations. This is where dairy ERP software comes into the frame.

The dairy ERP (Enterprise Resource Planning) integrates all critical processes into a single, unified platform. But what are those modules that make ERP so powerful? This blog will explore the key modules that help dairy businesses streamline operations, maintain quality standards, reduce waste, and make smarter business decisions.

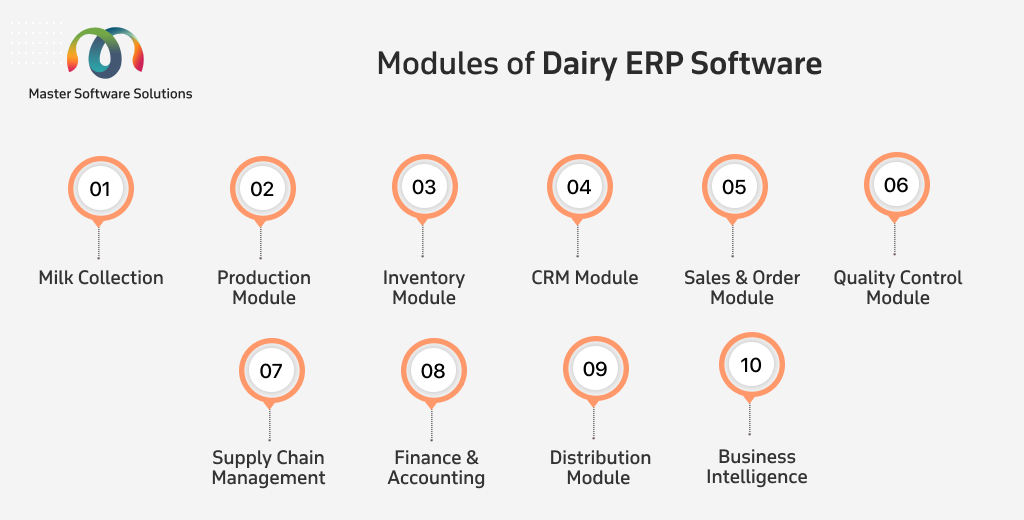

Modules of dairy ERP software

The dairy ERP system is a specialized platform that provides an end-to-end solution to manage, track, and trace your entire supply chain. It consists of multiple interconnected business management modules, providing a centralized platform. Here are the dairy ERP modules that help streamline operations:

Milk collection

The milk collection module is a core component of any dairy ERP system. It is designed to streamline and automate the milk procurement process from farmers, cooperatives, or collection centers. This module ensures accurate, real-time data capture and transparent transactions for efficient quality control and production planning. The features of the milk collection module are

- Farmer and vendor management – You can maintain a database of all the farmers, their profiles, supply history, and payment records.

- Milk quality testing integrations – Automatically records key parameters such as fat content, SNF (solid non-fat), temperature, and adulteration test results using integrated milk analyzers.

- Weightment automation – Capture the weight of milk received through weighbridges or electronic scales integrated with the ERP.

- Rate calculation engine – Automatically calculate payment based on quality parameters and predefined rate charts, ensuring fair and transparent compensation to suppliers.

- Shift-wise collection tracking – Record milk collection data for multiple (morning/evening) shifts with real-time updates across collection centres.

- Route and center management – Monitor milk collected by route or collection center to help optimize logistics and identify supply gaps.

- Receipts & acknowledgement – Generate instant receipts for every milk transaction to ensure transparency with farmers.

- Data sync & mobile support – Enable remote collection entries to sync data with the central ERP, even in low connectivity areas, via mobile apps or online data capture tools.

The milk collection module ensures accuracy and transparency in the procurement process, reduces manual errors and fraud, enables faster farmer payments, and builds trust. It also supports traceability of milk from farm to factory, enhancing quality control and production planning.

Production module

The production module in a dairy ERP system enables you to manage and monitor the entire milk processing lifecycle, from raw milk intake to the finished dairy products, including pasteurized milk, curd, butter, cheese, and ghee. It enables real-time tracking, quality control, and efficient resource utilization, ensuring every batch meets regulatory and consumer standards. Features of the production module are

- Production planning and scheduling – Plan daily or batch-wise production based on milk availability, product demand, and storage capacity.

- Recipe and BOM management – Define standard recipes and Bills of Materials (BOMs) for each dairy product, including quantity extracted, cultures, additives, and processing steps.

- Batch processing and monitoring – Track each production batch in real-time, including pasteurization, homogenization, separation, fermentation, and packaging stages.

- Yield management – Conduct quality tests (fat, SNF, microbial, etc.) at every stage and ensure compliance with food safety regulations (FSSAI, ISO, etc.).

- Production cost – Calculate real-time production costs, including raw materials, labor, utilities, and packaging. It helps with cost control and setting optimal pricing.

- Wastage and by-product management – Record and analyze production losses and by-products such as whey or skim milk for further utilization or disposal.

- Integration with inventory and sales module – Automatically updates finished goods inventory and triggers stock availability for the distribution and sales team.

The production module ensures consistent product quality, improving operational efficiency and production accuracy. It also reduces waste, downtime, and manual errors.

Inventory module

The inventory module in a dairy ERP system allows dairy businesses to gain complete visibility and control over their raw materials, packaging materials, semi-finished goods, and finished dairy products. It ensures accurate stock tracking, reduces wastage, and supports timely procurement and production planning, all of which are vital for managing perishable items with limited shelf life. Key features of the inventory module:

- Multi-warehouse & location management – Track inventory across multiple warehouses, cold storage facilities, distribution points, and production units.

- Real-time stock trading – Monitor the stock level of raw milk, additives, packaging materials (bottles, pouches, cartons), and finished product in real-time.

- Batch and expiration tracking – Manage products using batch numbers, manufacturing dates, and expiration dates to ensure FIFO (first-in, first-out) and reduce spoilage.

- Reorder alerts & safety stock management – Set minimum stock levels and receive alerts for timely replenishment to avoid stockouts or overstocking.

- Goods receipt and issue management – Track all incoming (purchase, transfers) and outgoing (production use, sales dispatch, wastage) inventory transactions.

- Stock valuation and costing – Automatically calculate inventory value based on methods (FIFO, LIFO), or weighted average, helping with accurate financial reporting.

- Production & sales integrations – Update inventory when raw materials are consumed in production or finished goods are sold/distributed.

- Wastage & spoilage recording – Track and analyze inventory losses due to spoilage, leakage, or expiration to improve future planning and reduce losses.

The inventory module of dairy ERP enhances accuracy and product traceability, preventing stockouts, overstocking, and expiry losses. It supports efficient production planning and procurement. Automated inventory management reduces manual errors and wastage, and a centralized database improves cost visibility and operational efficiency.

CRM module

The CRM module of ERP software for dairy industry helps dairy businesses manage and nurture relationships with distributors, retailers, institutions, and end customers. It provides a centralized platform to track customer interactions, manage sales pipelines, respond to inquiries, and deliver personalized experiences, ultimately driving customer satisfaction and loyalty in a competitive market. The features of dairy ERP CRM are

- Customer database management – Maintain profiles of all B2B and B2C customers, including contact details, order history, preferences, credit limits, and communication records.

- Lead and opportunity tracking – Capture leads from various channels (website, email, sales calls), quality them, and manage them through the sales funnel.

- Order and complaint tracking – Track customer orders, monitor delivery status, and manage service requests or complaints with timely resolution.

- Sales, billing, & support integrations – Sync customer data with sales and billing modules for seamless quoting, invoicing, and service management.

- Performance analytics & reporting – Analyze customer retention, sales conversion rates, satisfaction levels, and campaign effectiveness through detailed dashboards and reports.

- Customer segmentation & targeting – Segment customers based on behavior, geography, or buying patterns for targeted promotions or campaigns.

The CRM module strengthens customer relationships and brand loyalty, improving sales conversion and customer retention. The system enables you to respond quickly to queries and complaints. It supports data-driven marketing and personalized engagement. It also enhances visibility for sales team performance and customer trends.

Sales & order module

The sales and order management module is a vital part of this ERP that allows businesses to handle their entire sales process, from creating orders to fulfillment and invoicing. Given the shorter shelf life of dairy products, this module ensures accurate order tracking, timely deliveries, efficient dispatching, and a smooth customer experience. The features of the sales and order management module are

- Multi-channel order management – Capture and manage orders from various channels, including direct sales, mobile sales apps, distributor portals, and call centers.

- Customer-specific pricing – Apply custom pricing, volume discounts, credit terms, and promotional offers to a customer category or contract.

- Real-time product availability – Check store availability before confirming orders to avoid delays or rejection.

- Route and delivery schedules – Assign orders to delivery routes and schedule dispatches based on geography, customer type, or time preference.

- Recurring orders and subscription handling – Manage standing orders or subscription-based deliveries for customers who need a regular milk supply.

- Sales order lifecycle tracking – Monitor each order from confirmation to dispatch, delivery, and billing with real-time status updates.

- Invoicing & integration with finance – Generate sales invoices automatically upon delivery confirmation, and sync with accounting modules for receivable tracking.

- Returns and order cancellation – Handle returns due to damages, expiry, or order mismatches with proper tracking and inventory adjustments.

This module enables faster order processing, on-time deliveries, and minimizes order errors, stockouts, and missed sales. The system also helps you improve customer satisfaction through accurate fulfillment. It simplifies subscription management and recurring billing, offers sales insights and performance tracking by product, region, or customer.

Quality control module

The quality control (QC) module is a vital component of the ERP system, ensuring that every drop of milk and every dairy product meets strict industry standards for safety, freshness, and consistency. From raw milk collection to final packaging, this module helps businesses to implement quality checks, maintain compliance, and uphold brand trust. Key features of the quality control module are

- Quality parameter – Define quality criteria for raw milk and finished product, including fat, SNF, pH level, temperature, microbial load, color, taste, and shelf life.

- Milk quality testing at collecting centers – Capture test results directly from the milk analyzer at procurement points for real-time quality assessment and payment grading.

- In-process quality checks – Monitor critical points during pasteurization, homogenization, fermentation, and packaging to ensure consistency and prevent contamination.

- Finished product inspection – Conduct final checks on packaged products for compliance with regulatory standards and internal specifications.

- Automated alerts and hold mechanisms – Automatically flag non-compliant batches and prevent them from moving to the next stage or entering distribution.

- Lab testing & sample management – Record and track lab samples, test results, batch numbers, and any corrective action taken.

- Traceability & compliance reporting – Maintain end-to-end traceability of raw materials, processes, and final products to support food safety audits and compliance with standards like FSSAI, ISO, and HACCP.

- Integration with other modules – Seamlessly integrate with procurement, production, inventory, and sales modules to ensure only quality-verified products move through the supply chain.

The quality control module ensures consistent product quality and consumer safety, helping achieve regulatory compliance with ease. It reduces product recalls, customer complaints, and losses and enhances brand reputation and market competitiveness. The system provides real-time visibility into quality issues and solution actions.

Supply chain management

The supply chain management (SCM) module in a dairy ERP system plays a vital role in ensuring the smooth and timely flow of raw milk, materials, and finished dairy products across the value chain. From farmer to processing units and on to retailers or end customers, this module provides end-to-end visibility, coordination, and optimization of procurement, production, logistics, and distribution activities. This minimizes delays, reduces waste, and ensures product freshness. Features of the supply chain management module

- Procurement planning and vendor coordination – Plan and manage procurement of milk, additives, and packaging materials from multiple suppliers and cooperatives, ensuring quality and timely delivery.

- Demand forecasting – Use historical data, seasonal trends, and sales forecasts to plan procurement and production, aligning supply with demand.

- Logistics & route optimization – Plan and optimize milk pickup routes from collection centers and delivery routes for finished products, reducing fuel costs and delivery time.

- Cold chain management – Manage and monitor cold storage units, transportation temperature, and shelf life requirements to maintain the quality of perishable dairy products throughout the dairy supply chain.

- Supplier & transporter management – Manage contracts, rate agreements, delivery schedules, and performance metrics for all supply chain partners.

- Real-time tracking and alerts – Get real-time updates on stock movement, delayed shipments, and delivery status to quickly address disruptions.

- Handle returns and reverse logistics – Track returned goods due to damage or expiration and integrate them into inventory and quality workflows for proper resolution.

- Compliance & documentation management – maintain transport permits, quality certifications, and traceability documents required for regulatory compliance and audits.

The supply chain management module of an ERP software for the dairy industry enhances supply chain visibility and coordination and reduces logistical costs, wastage, and delays. This ensures product freshness, quality, and traceability. It can align procurement, production, and distribution efficiently, ensuring timely deliveries and improving customer satisfaction. The system enables you to make data-driven decisions to adapt to market fluctuations.

Finance & accounting

The finance and accounting module helps businesses manage cash flow, control costs, and maintain compliance with industry regulations and tax laws. This module seamlessly integrates with procurement, sales, inventory, payroll, and production modules to provide a real-time, accurate financial picture. These aspects are essential for making strategic business decisions in the fast-moving dairy sector. Key features of the finance and accounting module are

- General ledger management – Records and manages all financial transactions across departments, with automated postings from other ERP modules.

- Accounts payable & receivable – Track supplier invoices and payments (milk vendors, packaging suppliers), and manage receivables from distributors, retailers, and institutional buyers.

- Milk payment reconciliation – Automatically calculates and processes milk procurement payments/cooperatives based on fat/SNF rates and delivery records.

- Banking and cash flow management – Handle bank transactions, reconcile statements, and monitor cash inflows and outflows for better liquidity planning.

- Asset and expense management – Track and depreciate fixed assets (processing machines, delivery trucks) and manage operating expenses.

- Budgeting and forecasting – Prepare budgets, compare actual performance vs. budgeted figures, and generate financial forecasts for growth planning.

- Taxation & compliance – Automatically calculates GST, TDS, and other applicable taxes, generates tax reports, and supports audit processes.

- Financial reporting and dashboards – Generate balance sheets, profit & loss statements, cash flow reports, and customized financial KPIs for decision-making.

This module provides accurate, real-time financial insights and automates milk payment processing and invoice generation. It helps ensure regulatory and tax compliance and supports audit readiness and financial transparency. The system improves cost control, profitability analysis, and budget discipline.

Distribution module

The distribution module manages the movement of finished dairy products from the production facility to wholesalers, retailers, institutions, and end consumers. It focuses on speed, accuracy, and freshness, ensuring that dairy products are delivered through optimized routes with real-time visibility and complete traceability. Key features of the distribution module in dairy ERP

- Route planning and optimization – Create and manage efficient delivery routes based on geography, order volume, vehicle capacity, and delivery schedules to minimize travel time and fuel costs

- Vehicle and driver management – Assign vehicles and drivers to delivery tasks, track vehicle availability, and monitor driver performance and delivery efficiency.

- Order consolidation and load planning – Combine multiple orders for the same route and plan vehicle loads based on product types (milk curd, butter, and delivery priority)

- Cold chain monitoring – ensure proper temperature control throughout the delivery process to preserve the quality and shelf life of perishable products.

- Integration with sales and inventory – sync with sales orders and inventory levels to ensure accurate dispatch and reduce stockouts or over-commitments.

The distribution module ensures on-time, efficient delivery of perishable products and improves route performance, and reduces logistics costs. It helps you to maintain product quality through cold chain integrity. This module supports accurate billing, returns handling, and inventory control.

Business intelligence

The business intelligence (BI) module in the dairy ERP system empowers you with real-time, data-driven insights across all processes, from procurement and production to sales, distribution, and finance. It transforms raw operational data into actionable dashboards, reports, and forecasts that help optimize performance, reduce waste, and uncover growth opportunities in a highly competitive and perishable-driven industry. Features of business intelligence are

- Real-time dashboards – visualize key performance indicators (KPIs) across departments, including milk quality trends, production yield, sales performance, route efficiency, and farmer payments in real-time.

- Custom reports and data visualization – Generate customized reports using charts, graphs, and pivot tables for detailed analysis of procurement, inventory, sales, and financial metrics.

- Forecasting & predictive analytics – Analyze historical data to forecast demand, milk supply patterns, seasonal fluctuations, and future sales, enabling better procurement, production, and inventory planning.

- Profitability analysis – Track profitability by product, region, customer segment, or channel to identify top-performing SKUs and underperforming areas.

- Exception reporting and alerts – Automatically detect anomalies such as a sudden drop in milk quality, missed deliveries, production inefficiencies, or rising costs. It can also trigger alerts for quick resolution.

- Role-based access – Provide tailored insights to different teams, executives, plan managers, sales teams, and finance departments, based on their specific data needs.

- Integration with other modules – This can pull data from across the ERP (milk collection, quality, inventory, sales, finance) to provide a unified view of the business.

The business intelligence module enables data-driven decision-making at every level and improves operational transparency and accountability. It also supports better forecasting, planning, and resource allocation. This helps identify trends, risks, and opportunities, driving efficiency, profitability, and competitive advantage.

Conclusion

Adopting a comprehensive dairy ERP system with customized modules can help you gain real-time visibility, boost operational efficiency, and make data-driven decisions. Each module of the dairy ERP system works together to streamline processes, reduce manual errors, and ensure consistent product quality. The right system can help you drive profitability and growth, and stay ahead in a competitive and quality-sensitive market.

Master Software Solutions provides end-to-end ERP consulting services that include ERP implementation, customization, integration, migration, and ongoing support and maintenance. We work on Odoo and Microsoft Dynamics 365 to provide tailored solutions for your dairy business. If you are a dairy business seeking to improve your operational efficiency and productivity, schedule a call to discuss.