An efficient Odoo inventory management system is critical for seamless operations and customer satisfaction. If you are a retailer, distributor, or manufacturer, you’ll understand that juggling inventory levels, tracking movements, and optimizing storage can be a hassle. This blog explores how Odoo helps you manage your warehouse and its benefits.

Table of Contents

What is warehouse management?

Warehouse management involves efficiently managing and tracking day-to-day warehouse operations. Odoo enables warehouse management within the inventory module to optimize warehouse space, labor, and equipment, ensuring smooth and cost-effective storage of goods. Warehouse management includes:

- Receiving – Manage incoming goods, verify quantities and quality, and update inventory.

- Put-away – Set received goods into the designated storage location to maximize space and accessibility.

- Storage – Organize and manage inventory storage. Consider factors such as product type, turnover rate, and accessibility.

- Inventory management – Track and control the quantity and location of stock within the warehouse.

- Picking – Retrieving the right items and quantity from storage to fulfill customer demand.

- Packing – Prepare the picked item for shipment. Select appropriate packaging for safe transit.

- Shipping – Managing the outbound flow of goods. It includes labeling, loading into vehicles, and coordinating with carriers.

- Warehouse layout and design – Planning and optimizing the warehouse layout for efficient movement of goods.

- Labor management – Schedule and manage warehouse staff for efficient task completion.

- Safety and security – Implement and enforce safety procedures and security measures within the warehouse.

- Reporting and analysis – Track warehouse management key performance indicators (KPIs) to identify areas for improvement and make changes.

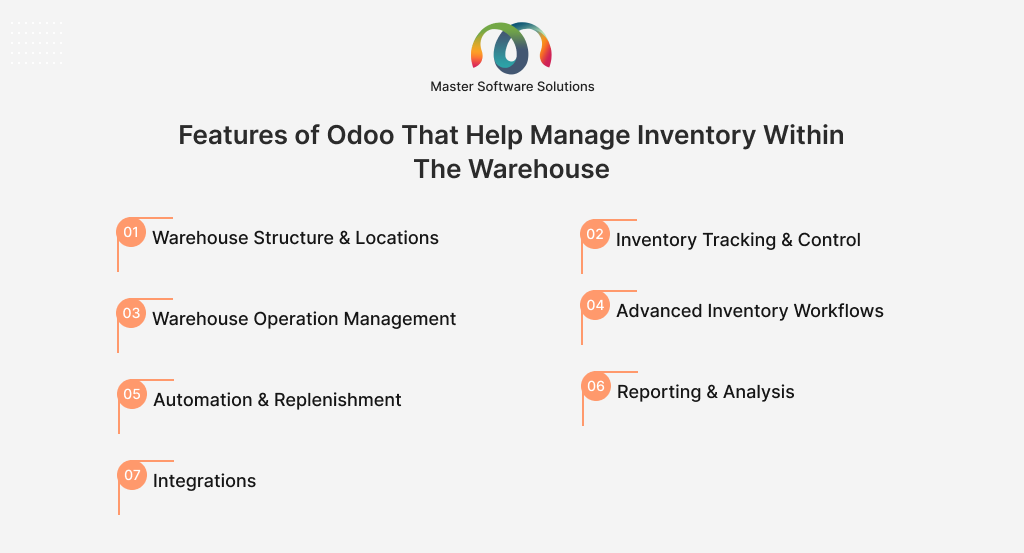

Features of Odoo that help manage inventory within the warehouse

Odoo offers various features within its inventory module to efficiently manage your warehouse. It provides robust features beyond basic tracking to optimize operations and inventory within the warehouse. The features of Odoo to manage inventory within the warehouse are:

Warehouse structure and locations

Odoo enables you to manage inventory across multiple warehouses from a single system. You can define storage locations within each warehouse for precise inventory placement and tracking.

Define location type, such as internal, vendor, customer, production, or transit. You can organize locations into a hierarchical structure for a clear view of the warehouse layout.

Inventory tracking and control

The Odoo ERP system offers real-time inventory visibility across all locations. You can integrate a barcode scanner to efficiently and accurately track stock from the time it is received till it is shipped. Track stock using lot and serial number tracking, essential for quality control, recalls, and warranty management.

The system enables expiration date management to implement FIFO/FEFO picking strategies and minimize wastage. You can manage and track different packaging units at various levels.

Warehouse operation management

You can define put-away rules and implement strategies for stock removal, picking waves and batches, packing management, and shipping management. Automate the direct incoming goods to an optimal storage location, based on factors such as product category, volume, and accessibility. Implement strategies like First-in, First-out (FIFO), Last-in, First-out (LIFO), and the closest location to optimize storage.

Advanced inventory flows

Odoo allows you to define push and pull rules to configure complex inventory workflows between locations and warehouses, including direct delivery (dropshipping) and cross-docking. The system can help you streamline the movement of stock between your warehouses. You can manage raw materials flow to subcontractors and receive finished goods receipts. The system allows you to define specific steps for inbound deliveries.

Automation and replenishment

You can set replenishment rules, defining minimum and maximum stock levels to trigger automatic purchase. You can plan production based on demand forecasts and inventory levels. Receive replenishment alerts for low stock levels.

Reporting and analysis

Track the financial value of your inventory with different costing methods. Auto-generate reports on current stock level, inventory movement, and stock turnover. Analyze future stock levels based on sales and purchase orders. Gain meaningful insights into warehouse efficiency and performance.

Integrations

You can integrate the inventory module for warehouse management with other Odoo apps, such as sales, purchase, manufacturing, and other modules. The system also supports integration with third-party systems such as e-commerce platforms (Adobe Commerce, Shopify, WooCommerce), CRMs (HubSpot, Salesforce), and accounting systems (Xero, Zoho, QuickBooks).

Types of locations in Odoo warehouse management

There are various locations in Odoo warehouse management that you can determine for efficient management. Each location in Odoo serves a specific purpose. The types of locations in Odoo warehouse management are:

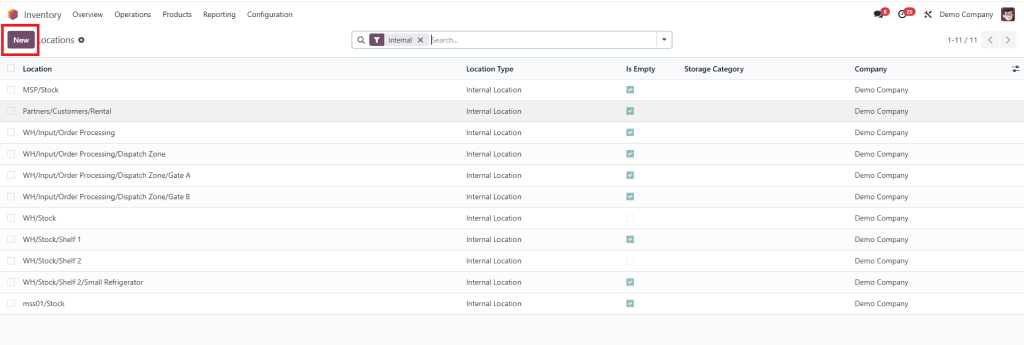

Internal location

They are the physical storage areas within your warehouse. They include shelves, aisles, and bins. The items stored in these locations are considered part of your inventory.

Vendor location

It is a virtual location that presents the source of your products and is stored with your vendor. These items are not considered part of your inventory.

Customer location

It is a virtual location that represents the destination of the product you are selling to your customers. These items are no longer part of your inventory.

Inventory loss

The virtual location is used to account for inventory discrepancies, including lost or damaged products. Increased count in this location reduces your stock level.

Production

The virtual area is also known as a staging area for raw materials consumed in manufacturing and for the output of finished products.

Transit location

It is a virtual location that is used to track your goods during inter-company or inter-warehouse transfers. These items are not considered to be part of your inventory.

View

It is a structural, virtual location used for organizing and creating a hierarchy of other locations within a warehouse. It doesn’t contain products.

Physical locations

This is a parent “view” location that groups all the customers and vendor locations.

Partner locations

A parent “view” location that can group all the locations within a warehouse.

Virtual locations

A parent “view” location that groups all the virtual locations, such as inventory loss, transit, and production.

Configurable locations in Odoo involve these steps:

These are the locations that you can configure from the Odoo inventory module. These locations enhance the system functionalities for effective warehouse management.

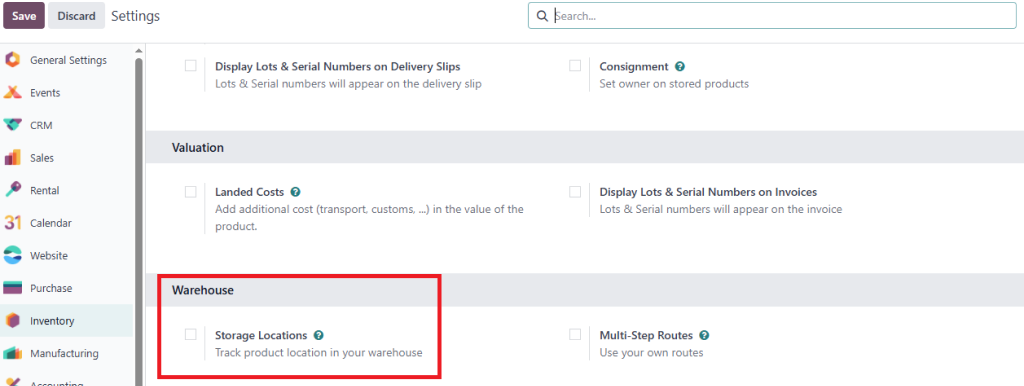

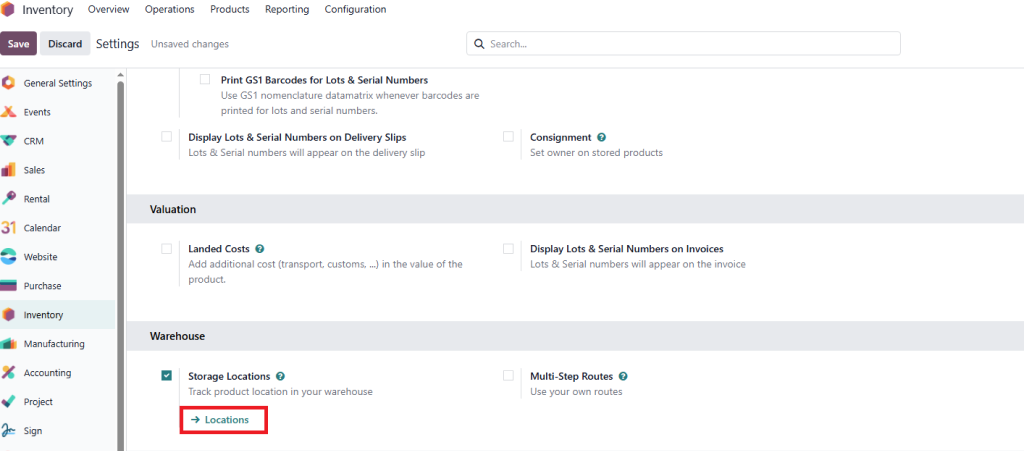

Enable storage locations

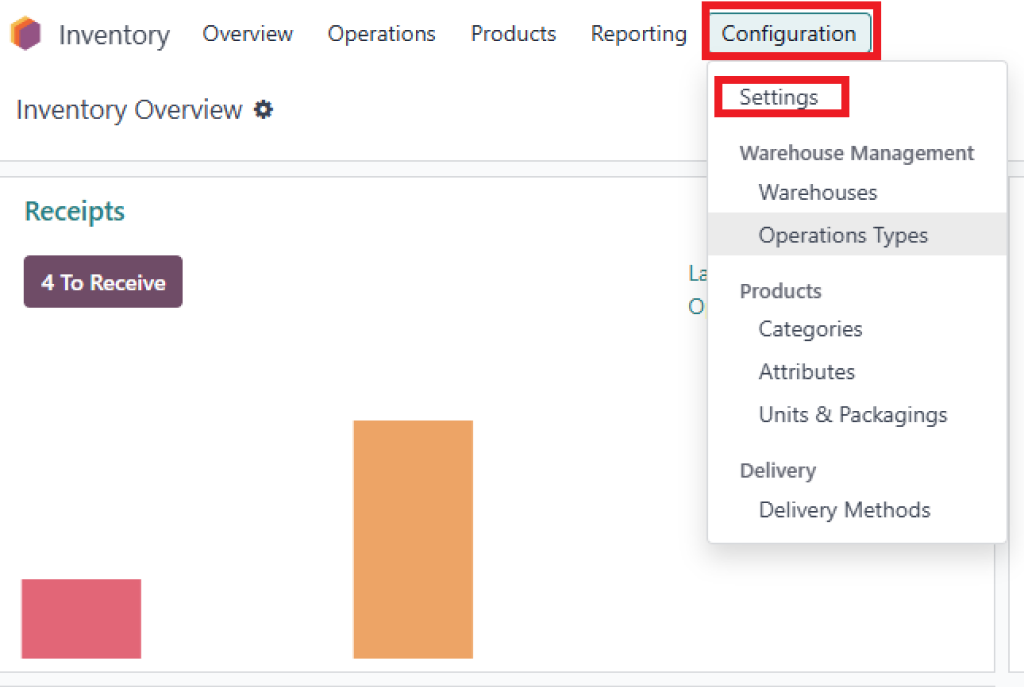

- Go to the Inventory module.

- Click on Configuration.

- Go to Settings and under the Warehouse section, enable Storage Locations.

- Click Save.

Create a new location.

- Go to the Inventory Module.

- Click on Configuration.

- Go to Locations and click on Create.

Define location details

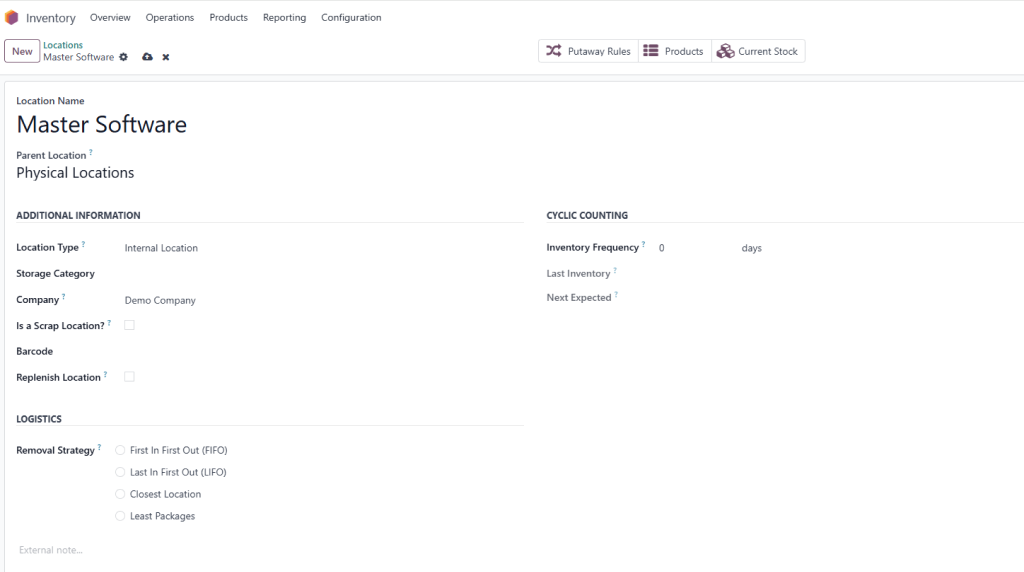

- Location Name – Give your location a descriptive name.

- Parent Location – Create a hierarchical structure to specify the warehouse or another location that this new location belongs to.

- Location Type – Choose an appropriate location type from the dropdown menu.

- Company – Select the company to which the warehouse and location belong.

- Is a Scrap Location? – Check this box if this location is specifically for storing scrapped or damaged goods.

- Barcode – You can assign a barcode to a location for easy identification and scanning.

- Replenish Location – Enable this if you want this location to be a destination for replenishment routes.

- Removal Strategy – Define the strategy for how items should be removed (FIFO, LIFO, or closest location) from this location in the logistics section.

- Inventory Frequency – Set the scheduled inventory counting frequency from the cyclic counting section.

How does warehouse management work in Odoo ERP?

Odoo ERP lets you easily set up a single or multiple warehouses for seamless warehouse management. You can add as many warehouses to your company as required.

Step-by-step workflow of the warehouse management system in Odoo:

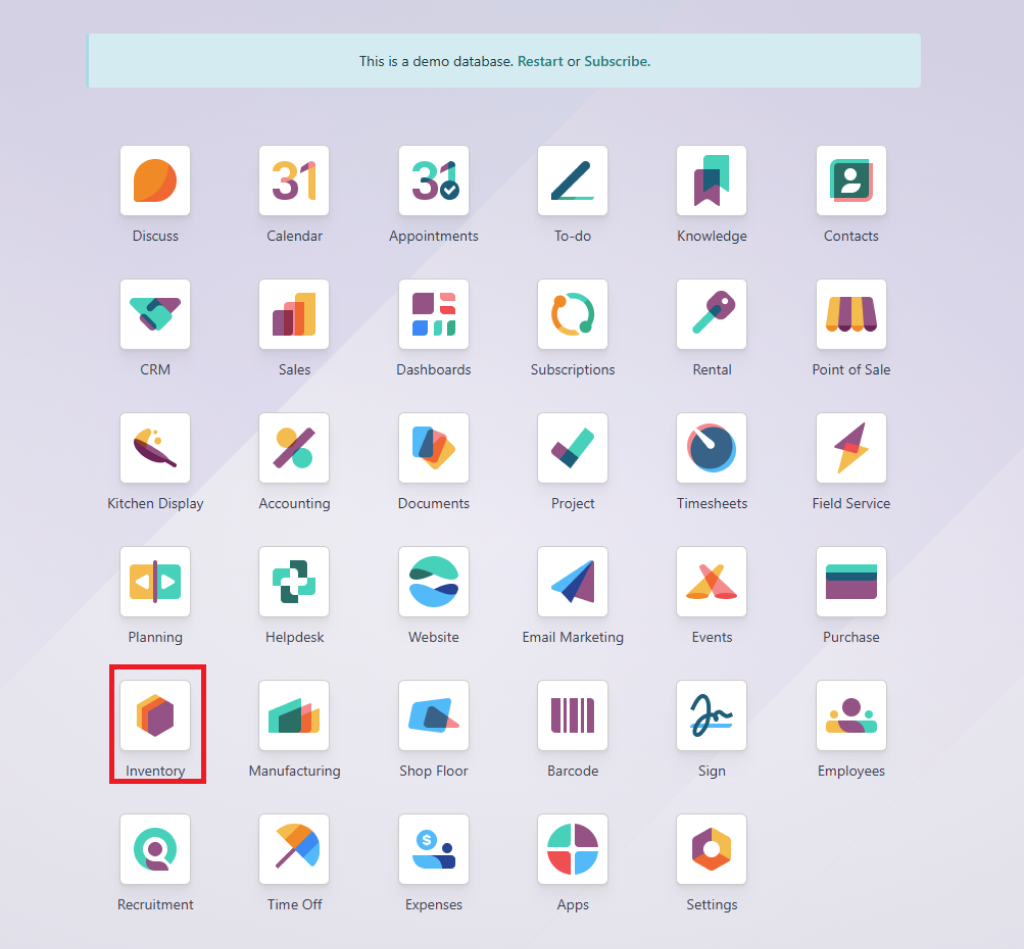

1: Log in to your Odoo account and click “Home Menu” to select the Inventory App.

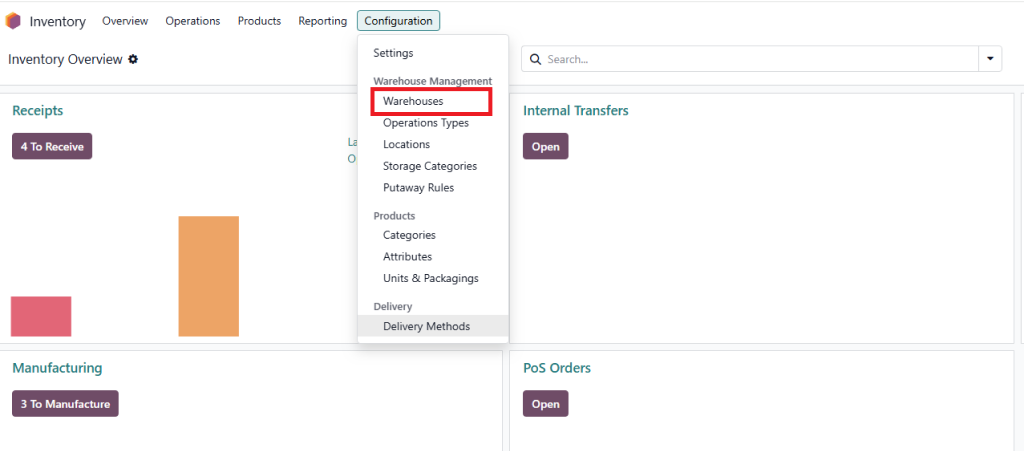

2: Click “Configuration” and go to “Settings”.

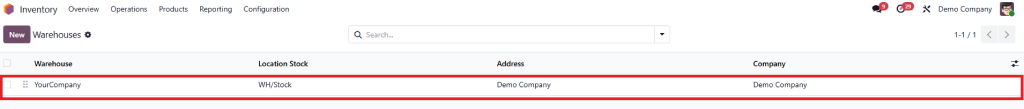

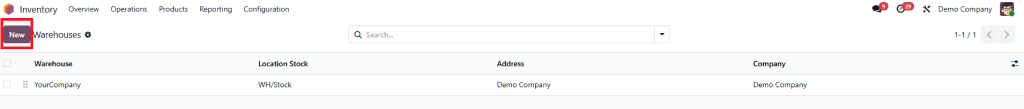

3: Go to the Configuration > Warehouses.

You can see the default warehouse for your company.

4: Click on “Warehouses” under the “Warehouse Management” Section of “Configuration”. Click on “New” to create a new Warehouse. Add the warehouse name, short name, and select address.

Updating Warehouse Configuration

You can set the Incoming and Outgoing Shipment processes. You can also choose to enable or disable resupply processes.

Click on “Location” under the “Warehouse Management” section of “Configuration” and click on “New”.

Add Location Name, Parent Location, additional information, cyclic inventory, and logistics strategy.

Manage the warehouse system in Odoo with Master Software Solutions

Master Software Solutions is a certified Odoo Ready Partner that offers end-to-end Odoo consulting services, including implementation, migration, development, integrations, and ongoing support and maintenance. We can help you seamlessly implement Odoo into your business. Schedule a call to discuss your business and explore how we can assist.