The dairy industry is one of the rapidly evolving industries and is driven by rising customer demand, stricter quality regulations, and the need for greater supply chain transparency. In today’s dynamic marketplace, an Enterprise Resource Planning (ERP) system has become a crucial tool for managing day-to-day operations and achieving new levels of efficiency and supply chain traceability. ERP systems are smarter, connected, and tailored to meet dairy-specific challenges of production, processing, and distribution.

This blog explores the latest ERP trends transforming the dairy industry, from AI-powered forecasting to real-time milk traceability, mobile access, cloud deployment, and more. These trends reveal how ERP is helping businesses stay agile, compliant, and competitive in an increasingly complex dairy supply chain.

This blog covers:

What is ERP for the dairy industry?

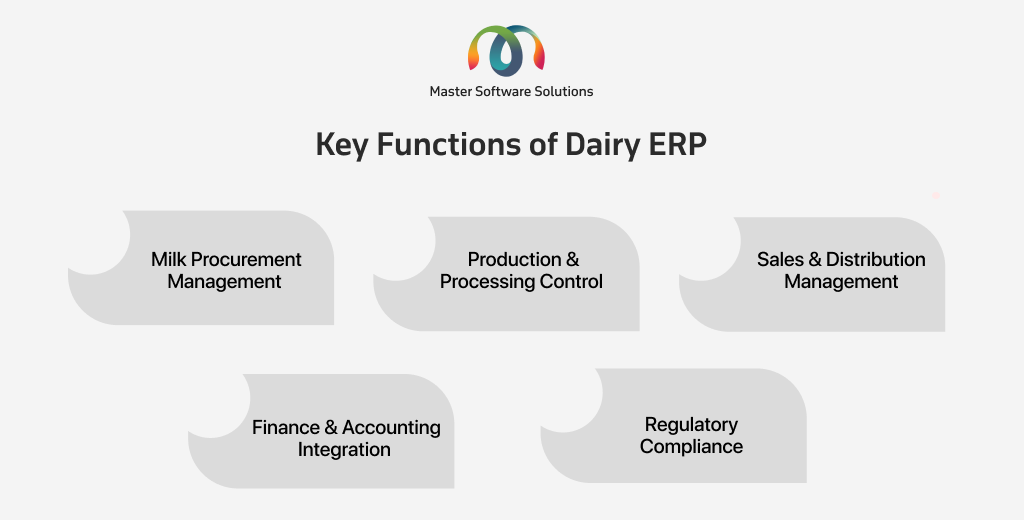

ERP (Enterprise Resource Planning) system for the dairy industry is a specialized software solution designed to streamline, automate, and manage the end-to-end operations of dairy businesses, from milk collection and processing to packaging, distribution, and sales. Unlike generic ERP, dairy-specific ERP platforms are tailored to address the unique challenges of the industry, such as milk perishability, batch tracking, quality control, seasonal fluctuations, and regulatory compliance. Key functions of dairy ERP:

- Milk procurement management – You can track milk collection from farmers or collection centres. The system automates quality checks, including fat/SNF content, temperature, and adulteration. It also calculates payments based on the milk quality and quantity.

- Production and processing control – The system can manage and handle processes like pasteurization, homogenization, and packaging. It can track yields, wastage, and by-products (cream, butter, or whey).

- Inventory and batch management – You can monitor raw materials, packaging items, and finished goods. It enables batch-wise traceability and expiration management.

Sales and distribution management – The system supports route planning, van sales, order fulfillment, and delivery tracking. It can handle both B2B (retailers or wholesalers) and B2C (home deliveries) channels. - Finance and accounting integration – The system automates billing, cost accounting, farmers’ payments, and compliance reporting.

- Regulatory compliance – The system ensures adherence to food safety standards (FSSAI, ISO, HACCP). It maintains audit trails and documentation for inspections.

Dairy businesses’ pain areas

Freshness, consistency, and compliance are non-negotiable in the dairy industry. From sourcing raw milk to delivering processed dairy products, dairy businesses must be able to manage a complex network of suppliers, logistics, quality checks, and the evolving market. Amid these complexities, dairy businesses face a range of operational and strategic challenges that can impact profitability and growth. Here are some of the most pressing pain points of a dairy business:

Fluctuating milk prices

Seasonal supply, global demand, government policies, and feed costs influence milk prices. These unpredictable fluctuations make it challenging for dairy businesses to forecast revenue, control costs, or maintain stable relationships with farmers.

Supply chain complexities

The dairy supply chain involves multiple touchpoints, from farmers and chilling centres to processing units and distribution networks. Coordinating all these elements while ensuring freshness and efficiency adds significant complexity.

Quality control demands

Maintaining consistent quality across perishable and sensitive products, including milk, cheese, and yoghurt, is critical. Factors such as temperature control, hygiene, and contamination detection require continuous monitoring and robust ERP systems to ensure high milk quality.

Evolving customer demands

Consumers prefer fresh, organic, value-added dairy products with transparent sourcing. Meeting these preferences while managing operational constraints requires agility and innovation.

Traceability

In the case of quality issues or recalls, dairy businesses must quickly trace batches back to their origin. The lack of real-time traceability can lead to compliance violations and damage to brand reputation.

Shorter shelf-life

Most dairy products have a short shelf life, leaving little scope for errors in production or delays in distribution. Any inefficiency can result in spoilage and lost revenue.

Regulatory compliance

The dairy industry is heavily regulated. Compliance with food standards (FSSAI, ISO, or HACCP) necessitates extensive documentation, reporting, and audit readiness.

How can ERP help dairy businesses?

ERP systems unify operations, eliminate manual errors, and drive smarter decision-making across procurement, production, inventory, distribution, and finance. Here is how ERP empowers dairy businesses to overcome operational challenges and achieve sustainable growth

Real-time visibility

ERP provides a centralized dashboard with real-time data on inventory, production, milk collection, quality tests, and sales. This enables managers to make quick, informed decisions and respond proactively to changes in demand or supply chain disruptions.

Efficiency & productivity

Automating routine tasks such as farmer payments, procurement, order processing, and reporting, ERP reduces manual workload and human errors, freeing up time and resources for strategic activities.

Optimal inventory levels

ERP helps track stock levels of raw milk, ingredients, packaging material, and finished goods. It enables accurate forecasting and replenishment, minimizing both stockouts and overstocking, which is critical for products with a short shelf life.

Streamlined production

It manages production planning, batch processing, yield tracking, and by-product utilization. ERP ensures the right quantity is produced at the right time, avoiding both shortages and wastage.

Quality checks

Quality control checkpoints, such as fat/SNF content, temperature, contamination, and shelf life, can be integrated into the production workflow. ERP ensures only compliant batches move forward, reducing the risk of recalls or consumer complaints.

Cost control

ERP offers granular visibility into costs across procurement, production, and distribution. Identifying inefficiencies and automating cost tracking can help dairy businesses improve profitability and reduce waste.

Sustainability and transparency

Modern dairy ERP systems support traceability, eco-friendly packaging monitoring, and responsible sourcing. They help businesses align with sustainability goals and provide transparency to consumers and regulators.

Latest ERP trends in the dairy industry

As technology advances and consumer expectations evolve, the dairy industry is undergoing a significant digital transformation. Modern dairy ERP systems have evolved and become intelligent, adaptive platforms that enable full-scale automation, traceability, compliance, and business optimization. Let us explore these latest trends in the dairy industry and how they are reshaping operations.

AI-powered processes

The integration of artificial intelligence has transformed the dairy industry, allowing businesses to work more efficiently. It has added intelligence and automation to ERP systems, optimizing operations. Key applications of AI in dairy ERP are:

- Demand forecasting – AI utilizes historical sales, seasonality, and weather data to predict future demand for milk and dairy products, helping optimize production planning.

- Predictive maintenance – Integrating sensors with ERP can predict when dairy equipment (pasteurizers or chillers) may need maintenance, reducing downtime.

- Route optimization – AI helps plan the most efficient delivery routes based on real-time traffic, customer preferences, and perishability of products.

- Smart procurement – AI algorithms analyze procurement trends and suggest optimal times and vendors for raw material purchase, considering price fluctuations and lead times.

Implementing artificial intelligence helps reduce operational costs, lower wastage and spoilage, improve accuracy and efficiency, and enable businesses to make informed decisions.

Blockchain integration

Blockchain brings transparency and trust to the dairy supply chain by recording every transaction in a secure, tamper-proof digital ledger. Integrating blockchain into ERP enables end-to-end product traceability, essential in quality-sensitive industries such as dairy. Blockchain key applications are

- Source-to-shelf tracking – From milk collected at the farm to final product delivery, every step is traceable via a blockchain ledger.

- Tamper-proof quality records – Quality checks, test results, and certifications are securely stored and can be accessed at any time.

- Simplified recall management – In the event of contamination or a defect, blockchain enables quick and accurate traceback of affected batches.

- Consumer transparency – Brands can offer QR codes on packaging that let customers view product origin, quality standards, and freshness in real-time.

Blockchain implementation can increase consumer trust, enhance food safety compliance, and simplify audits and regulatory reporting.

Advanced customization

Generic ERP systems often lack the flexibility and features needed by dairy businesses. Today’s ERPs are being custom-built or deeply customized to address the dairy sector’s unique needs. At Master Software Solutions, we offer tailor-made dairy ERP for manufacturers, enabling dairy businesses to streamline their entire dairy supply chain. Key custom ERP modules include

- Milk collection & farmer management – Tracks milk received from multiple farmers or cooperatives, automates fat/SNF testing, and calculates payments based on quality.

- Batch processing & by-product management – Manages processing of raw milk into multiple products (curd, ghee, butter, cheese) and tracks by-product utilization.

- Shelf-life monitoring – Automatically flags items about to expire and optimizes stock rotation.

- Chilling centre & tanker integration – Integrates with chilling centers and GPS-enabled tankers to track real-time temperatures and movement of raw milk.

- Mobile access for field agents – Sales reps and procurement agents can access data and update transactions directly from the field via a mobile ERP interface.

Other emerging trends

Beyond AI, blockchain, and advanced customization, several other technological innovations are reshaping how ERP systems support dairy businesses. These emerging trends have catered to the needs for mobility, connectivity, agility, and sustainability in a highly competitive and perishability-driven environment. Here are some of the emerging trends in ERP for dairy businesses:

Cloud-based ERP

They are hosted on the internet rather than on-premises servers, which makes them accessible from anywhere with an internet connection. Advantages of cloud-based ERP are:

- Anywhere, anytime access – Perfect for dairy businesses with multiple plants, distribution centers, or field operations. Managers and staff can log in from offices, plants, or even milk chilling centers.

- Scalability – Easily add new users, locations, or features as the business grows.

- Lower IT costs – Reduces the need for in-house servers and IT maintenance.

- Automatic updates – The software is always up-to-date with the latest features and security patches.

Cloud dairy ERP systems enable better coordination between milk collection centers, processing plants, warehouses, and delivery teams.

IoT (Internet of Things) integration

IoT devices, such as sensors, RFID tags, GPS trackers, and temperature monitors, can be integrated with ERP systems to deliver real-time data on physical conditions and the movement of goods. Use cases of IoT integration with ERP are:

- Temperature monitoring – Sensors in milk tankers and cold storage units track and report real-time temperature to ensure freshness.

- Milk tank level sensors – Automatically record milk volumes in storage tanks or chilling units.

- GPS in milk tankers and delivery vans – Enables route tracking and live updates on vehicle location and delivery status.

- Machine performance monitoring – Sensors on dairy processing equipment detect inefficiencies or maintenance needs.

IoT device integrations can prevent spoilage and ensure quality, improve fleet and asset management, and enhance automation and response time.

Sustainability and compliance reporting

With increasing pressure to reduce environmental impact, ERP systems are evolving to support sustainability tracking and regulatory compliance management. Features of sustainability and compliance reporting in ERP are:

- Energy and water usage monitoring – Tracks water consumption per batch or production line.

- Waste logs management – Monitors and reduces product, water, or packaging waste.

- Regulatory documentation – Generates reports required by FSSAI, HACCP, ISO, and other food safety authorities.

The sustainability and compliance reporting in ERP aligns with global sustainability goals, prepares businesses for ESG (Environmental, Social, and Governance), and enhances brand value for eco-conscious consumers.

How does Master Software Solutions help dairy businesses?

Master Software Solutions is an IT service-based company that provides end-to-end digital transformation services to a range of industries, including the dairy industry. We offer ERP consulting and AI business process & consultation services to help you smartly navigate the complex dairy market landscape and stand out from the competition. Are you a dairy business owner seeking to level up your operations? Schedule a Consultation with us.