The beverage industry has always been fast-paced, highly competitive, and is customer-driven. From managing production to tracking distribution and ensuring regulatory compliance, the beverage industry faces complex operational challenges in its day-to-day tasks. This is where beverage ERP systems come in.

It includes multiple stakeholders, including suppliers, manufacturers, distributors, and retailers. Integrating all beverage business processes into a single ERP platform enables automated inventory management, allows real-time production tracking, improves sales forecasting, and simplifies compliance with food standards. This blog explains how beverage ERP has revolutionized the industry and why it has become an essential tool for modern beverage companies.

This blog covers;

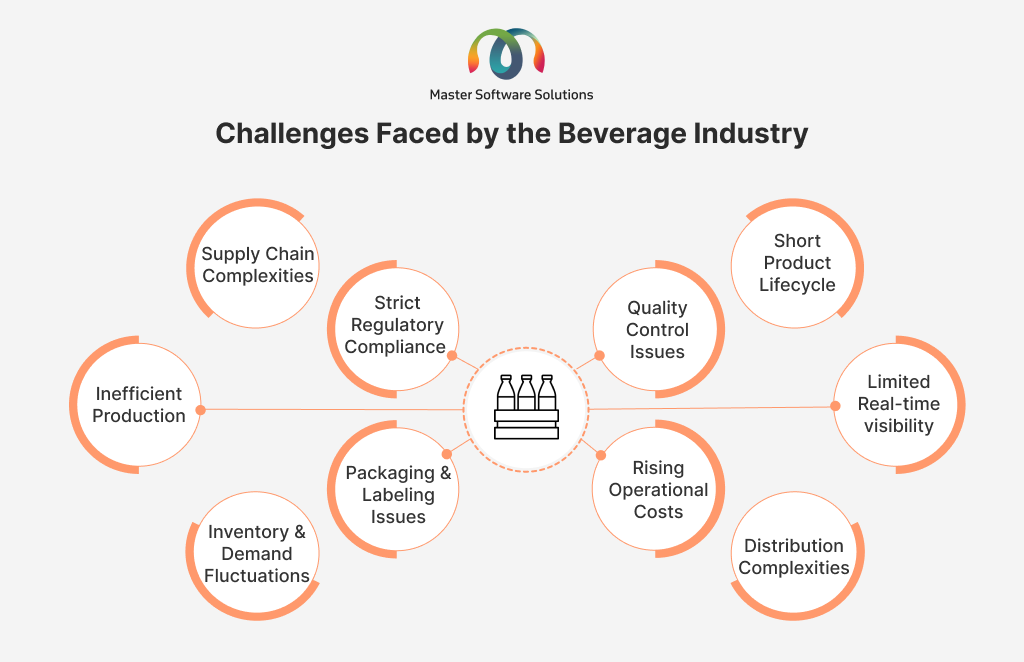

Challenges faced by the beverage industry

The beverage supply chain is one of the most complex supply chains. The industry is under consistent pressure to innovate, meet customer expectations, and maintain operational efficiency. The potential bottlenecks faced by the beverage industry are:

Supply chain complexities

Beverage businesses manage a multi-tier supply chain that involves raw materials, packing vendors, production facilities, and distribution channels. Disruptions at any point can result in delayed shipments, supplier shortages, or transportation issues, which can slow down production and impact delivery timelines. It is crucial to ensure smooth coordination between these moving parts.

Inefficient production

Outdated machinery or disconnected systems can lead to inefficiencies in scheduling, batch processing, and line utilization. The lack of automation and visibility can lead to production delays, downtime, or overuse of resources, reducing overall productivity and increasing costs.

Inventory and demand fluctuations

Consumer demand for beverages can be unpredictable due to seasonality, promotions, or shifting preferences. This makes maintaining optimal inventory levels difficult, leading to overstocking or understocking. Overstocking can lead to spoilage, especially for perishable drinks, while understocking can result in lost sales and customer dissatisfaction.

Packaging and labeling issues

Packaging is critical for beverage marketing and compliance. Labelling errors, such as incorrect nutritional information, missed expiration dates, or barcode issues, can result in regulatory violations and product recalls. Additionally, managing multiple SKUs for various markets and package types complicates matters.

Strict regulatory compliance

The beverage industry is governed by strict food safety and regulations, including FSSAI, FDA, and ISO standards. Companies must accurately track their ingredients, production batches, and shelf life. Non-compliance with these regulations can lead to heavy fines, damaged reputation, or halted operations.

Quality control and product consistency

Customers want every bottle to deliver the same taste and quality. Maintaining consistency across batches, especially when scaling operations or working with multiple suppliers, is a constant challenge. Inadequate quality checks can lead to spoilage, safety issues, or damaged brand image.

Rising operational costs

Costs related to raw material, packaging, labor, and transportation continue to rise. Without efficient systems to monitor and optimize expenses, beverage companies struggle to maintain their profit margins.

Short product lifecycle

Trends in the beverage market change quickly as customers seek new flavours, healthier options, and more environmentally friendly packaging. This forces companies to innovate quickly, often shortening the lifecycle of the existing products and increasing the pressure on the R&D and marketing teams.

Limited real-time visibility

Production, inventory, sales, and distribution are just a few of the disjointed departments that many beverage companies run, and they use different tools. Decision-making is slowed down and real-time access to data is restricted by this setup, making it either difficult to respond to issues or leverage opportunities.

Distribution and logistics complexities

Delivering beverages to retail outlets, supermarkets, or directly to consumers involves route optimization, cold chain management, and coordination with third-party logistics providers. Managing returns, empty bottles, and delayed deliveries further complicates distribution efforts.

Adopting beverage ERP systems to streamline operations

ERP for beverage industry provides robust features and functionalities to simplify and optimize operations. It aims to improve business efficiency, throughput, and profits while reducing the overall expenses. The features and functionalities of ERP for the beverage industry are:

Batch and recipe management

The ERP system enables you to manage recipes and formulations for different products and flavors. They track batch production to ensure consistency, traceability, and compliance with food safety standards.

Real-time inventory management

Unifying business operations into a single ERP platform provides real-time tracking of raw material, packaging, and finished goods. This prevents overstocking or stockouts, helping reduce waste, especially for perishable ingredients, and ensuring inventory is aligned with demand.

Production planning and scheduling

The advanced planning tools of beverage manufacturing ERP allow manufacturers to schedule production runs based on sales forecasts, seasonal trends, or raw material availability. This minimizes downtime and maximizes machine and labor efficiency.

Quality control and assurance

The system includes built-in quality checks at various stages to ensure product consistency and compliance with regulatory standards. The system can flag deviations in pH levels, temperature, taste, or packaging integrity.

Regulatory compliance and traceability

You maintain detailed records for audits and ensure compliance with global food and beverage regulations. They provide complete product traceability, from raw material sourcing to distribution, which is helpful in case of recalls or inspections.

Packaging and labeling automation

Integrated labelling features generate and manage multiple label formats based on regional or product specifications. It reduces errors and ensures packaging adheres to regulatory and brand standards.

Demand forecasting and sales analytics

The system can analyze historical sales, seasonality, and market trends to generate accurate forecasts, enabling businesses to align their production, procurement, and distribution.

Multi-channel order management

You can integrate multiple ordering platforms (retail stores, distributors, or e-commerce platforms) with the system’s order tracking and processing. This enables efficient fulfillment, invoicing, and customer service.

Warehouse and logistics management

Beverage ERP integrates warehouse operations with transport planning, optimizing order picking, packing, and dispatch. It includes features such as route optimisation, GPS tracking, and return handling to help streamline the entire delivery cycle.

Finance and cost accounting

The system can consolidate financials across production, sales, and supply chain activities, enabling accurate cost tracking, margin analysis, budgeting, and real-time profitability insights.

Equipment maintenance scheduling

The preventive maintenance module tracks equipment health and schedules routine checks to avoid production breakdowns and reduce downtime.

Mobile and cloud access

Modern beverage ERP systems offer mobile-friendly dashboards and cloud-based access, allowing managers and field teams to monitor and manage operations remotely in real-time.

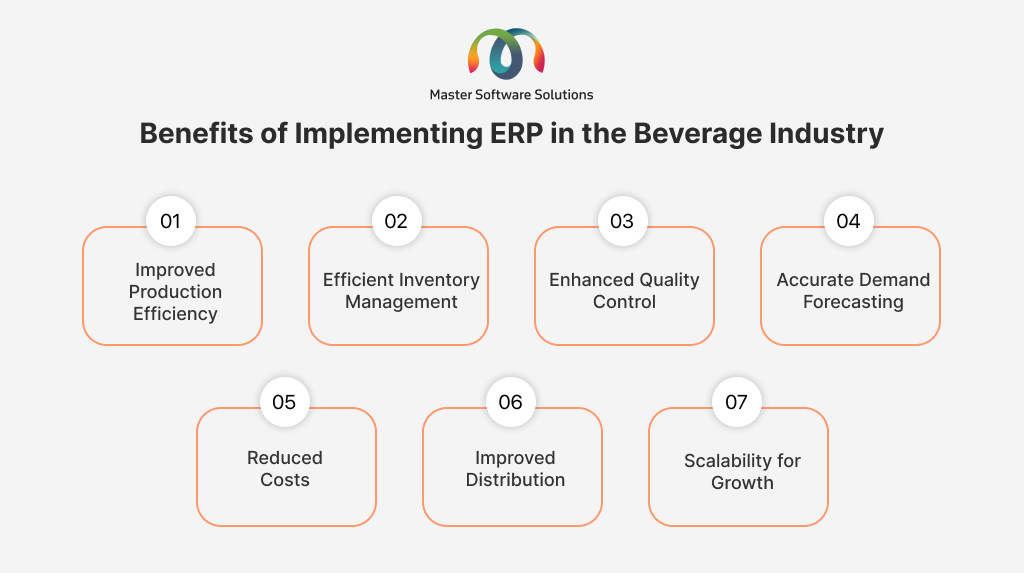

Benefits of ERP for the beverage industry

Implementing an enterprise resource planning system streamlines and optimizes business operations. It automates processes, improving data accuracy, and ensures the production and order fulfillment of the right products. The benefits of beverage ERP are:

Improved production efficiency

Automated scheduling, batch control, and real-time monitoring help optimize manufacturing workflows. This results in less downtime, more efficient resource utilisation, and faster turnaround on production orders.

Efficient inventory management

Real-time tracking of raw materials, packaging, and finished goods reduces the risk of overstocking or spoilage, especially for perishable ingredients, and minimizes waste through smarter stock rotation and forecasting.

Enhanced quality control

Integrated quality checks and compliance monitoring ensure that every batch meets regulatory and brand standards. This improves product consistency and reduces the risk of recalls or complaints.

Accurate demand forecasting

The ability to analyze trends, market data, and seasonal patterns provides accurate demand forecasts. This enables beverage companies to plan production and procurement more effectively, avoiding both shortage and excess inventory.

Reduced costs

Automating routine tasks, optimizing workflows, and minimizing errors help reduce labor costs, material waste, and overhead expenses, boosting overall profitability.

Improved distribution

Real-time order management, route optimization, and shipment tracking ensure timely delivery and better coordination with distributors. This improves customer satisfaction while reducing delivery errors.

Scalability for growth

As the beverage business expands through a new product line, region, or channel, ERP systems support additional users, processes, and integrations with disruption.

How does Master Software Solutions help the beverage industry?

Master Software Solutions is an IT service-based company that provides ERP consulting services for a wide range of industries, including the beverage industry. We provide ERP consultation, implementation, configuration, migration, and customization services. Our ERP services extend to ongoing support and maintenance. We work on ERP platforms such as Odoo and Microsoft Dynamics 365 to provide tailor-made ERP solutions for specific industries.