How Artificial Intelligence (AI) Is Helping The Dairy Industry?

The global dairy market is expected to be worth US$893 billion in 2022, with a projected increase to US$1,243 billion by 2028. Millions of households begin their day with a fresh glass of milk. Behind that lies a complex and delicate supply chain, where timing, temperature, and traceability are everything.

But what happens when unexpected delays, mismanaged inventory, or missed quality inspections threaten that journey?

In the dairy industry, a few hours can mean thousands of litres lost; simple dairy ERP software solutions are no longer enough. That’s where Artificial Intelligence steps in.

Imagine an ERP integrated with smart sensors that can detect milk spoilage before it happens, AI-powered algorithms optimizing delivery routes in real-time, and predictive tools managing fluctuating demand, all without human intervention. Master Software Solutions can help you implement AI into your dairy ERP to enhance its efficiency and your productivity.

This blog explains how artificial intelligence (AI) is transforming the milk supply chain from farm to fridge, ensuring freshness, efficiency, and profitability at every stage.

This blog covers;

Understanding the role of artificial intelligence in the dairy industry

The dairy industry is no stranger to the complexities, from timely milk collection and quality control to ensuring processing and distribution. With a rise in demand, shrinking margins, and growing consumer expectations for freshness and traceability, dairy businesses are now modernizing their operations.

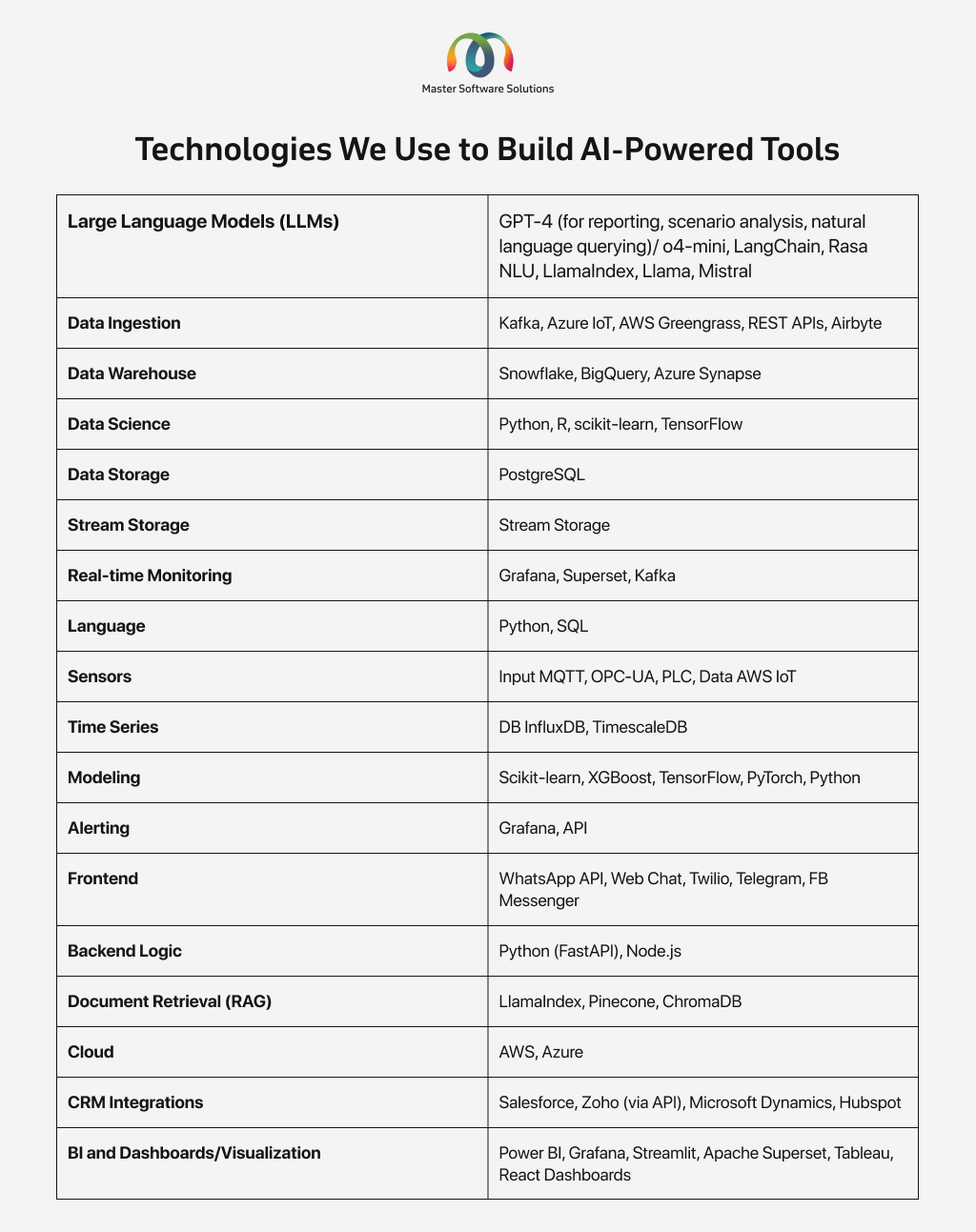

Artificial intelligence utilizes Machine Learning algorithms, computer vision, IoT, natural language processing, and big data analytics to perform actions from ERP software for dairy manufacturers.

- Machine learning can be used for demand forecasting, quality prediction, supplier performance analysis, and defect detection. Tools: TensorFlow, Scikit-learn, PyTorch, and AWS SageMaker.

- Computer vision can automate quality inspection and detect adulteration. Tools: OpenCV, YOLO, Google Vision AI, and Amazon Rekognition.

- The Internet of Things (IoT) is used for real-time tracking of temperature, humidity, and movement during transportation and storage. It can also monitor the health of the equipment in processing plants. Devices used: RFID tags, GPS trackers, temperature sensors, and pressure gauges.

- Natural language processing (NLP) is used for AI chatbots for customer service and farmer support, voice assistants for hands-free operations, and feedback analysis. Platforms: OpenAI, ChatGPT-4, LlamaIndex, and Rasa.

- Cloud computing is used to centralize data storage and processing, scalable AI development, and seamless integration between systems (ERP, CRM, logistics). Platforms: AWS, Microsoft Azure, Google Cloud Platform

- Big data analytics can help you analyze a large volume of the supply chain. It generates actionable insights and performance reports. Tools: Apache Hadoop, Spark, Snowflake, Power BI, and Tableau.

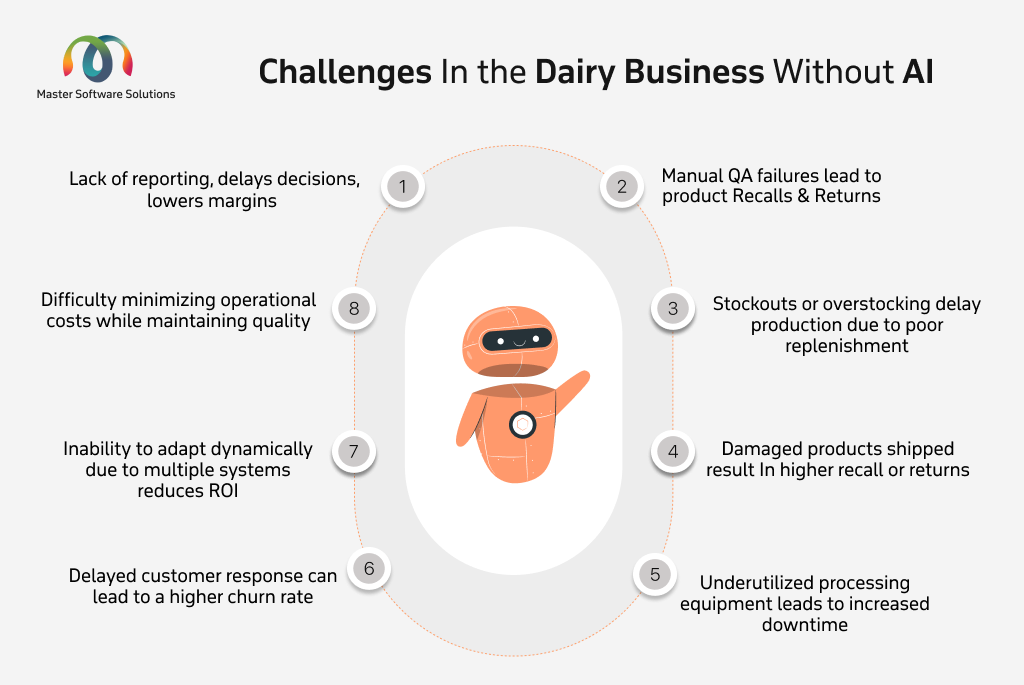

Challenges in the dairy business without AI

The dairy industry operates on tight timelines, delicate product conditions, and high customer expectations. Without AI, businesses face several challenges that impact efficiency, product quality, and profitability. Here is how the absence of AI can create dairy supply chain disruptions.

Instinct-driven decisions cause delays & poor customer experience.

Traditional dairy operation decisions are made manually, whether it is planning production schedules, routing delivery vehicles, or responding to disruptions. These decisions are based on experience rather than real-time data, resulting in slow and reactive processes. This causes delays in responding to demand fluctuations, equipment breakdowns, and route changes, which can lead to missed deliveries, wasted milk, and dissatisfied customers.

Example: If a milk chiller stops during the night due to technical issues and there is no AI alert system, staff may discover it too late, leading to significant spoilage and losses.

Lack of reporting delays decisions, lowers margins

Dairy businesses that do not use AI-powered monitoring systems frequently lack real-time visibility into what is happening. Issues such as transport delays, temperature breaches, or supply shortages might not be detected immediately. These blind spots can cause delays, product spoilage, and lost sales opportunities, resulting in financial losses and reduced revenue.

Example: A delayed milk tanker delivery to traffic might go unnoticed, impacting the entire production timeline for that day.

Manual QA failures lead to product racalls & returns

Manual quality checks are labor-intensive and prone to human errors. Without AI tools such as computer vision defect detection or machine learning-based quality analysis, it is hard to ensure uniform product quality. Variations in fat content, adulteration, or microbial contamination may occur in the absence of AI defect detection, leading to regulatory problems, product recalls, and harm to a brand’s reputation.

Example: A batch of milk contaminated due to improper storage may still be packaged and dispatched if not identified through AI-based inspection.

Stockouts or overstocking delay production due to poor replenishment

Inventory in the dairy industry must be managed with precision as milk and related products are highly perishable. Manual tracking is inefficient and prone to errors, resulting in stockouts, overstocking, or product wastage due to expiration. Overstocking leads to waste, while stockouts mean lost revenue. Without AI-driven inventory forecasting, replenishment decisions are often inaccurate. This leads to product spoilage and missed sales opportunities, ultimately resulting in financial losses.

Example: a lack of visibility into the expiration dates of stored milk can result in the delivery of expired stock.

Damaged products shipped result in higher recall or returns

Without AI-powered traceability, it is challenging to trace milk batches from farm to shelf, slowing down investigations during product recalls. This leads to businesses taking longer to identify affected batches, resulting in wider recalls, increased liability, and reputational damage. Shipping damaged or spoiled products can result in customer dissatisfaction and hampers brand image.

Example: In a contamination case, if you can’t trace the batch origin, you may need to recall more products than necessary.

Underutilized processing equipment leads to increased downtime

Without AI, production machines are often maintained reactively, only when something breaks down. Also, there is no optimization of machine usage based on demand trends. This increases downtime, raises maintenance costs, and underuses processing capacity.

Example: A pasteurizer (pasteurization processing machine) runs at full capacity even when the demand is low, wasting energy and resources.

Delayed customer response can lead to a higher churn rate

Handling customer service manually, whether for order changes, complaints, or enquiries, leads to slow responses. For a B2C or subscription-based model, this can cause customer dissatisfaction. This results in low customer experience and low retention. The businesses can miss opportunities for upselling or timely resolutions.

Example: A customer wants to pause their subscription, but a delay in manual handling results in unnecessary delivery and wasted product.

Inability to adapt dynamically due to multiple systems results in reduced ROI

Without AI, processes such as milk collection, chilling, packaging, and delivery are scheduled in advance with little flexibility. It is impossible to adapt dynamically to real-time factors. This makes processes inefficient, especially during unexpected changes such as a spike in demand or a vehicle breakdown, reduces ROI and increases the operational costs.

Example: If one delivery route becomes unavailable, the system can’t automatically reroute the delivery truck to maintain the cold chain.

Difficulty in minimizing operational costs while maintaining quality

Operations require a larger workforce, longer processing times, and involve more waste and inefficiency. Without AI, it is difficult to minimize costs while maintaining quality. Due to this, the margin reduces, especially in competitive markets. Businesses need to spend more to maintain service levels, which increases expenses and lowers revenue.

Example: A dairy plant using manual scheduling may overproduce during low demand, resulting in financial losses and product waste.

How can AI help you improve your dairy business operations?

AI is transforming dairy production by automating complex tasks, predicting issues before they arise, and enabling smarter, real-time decisions across the production line. From optimizing daily schedules and maintaining equipment to ensuring consistent product quality and reducing energy costs, AI is helping dairy businesses operate more efficiently and sustainably. Here is how AI is helping dairy businesses improve operations

AI-optimized schedules align production with demand, ensuring optimal stocks

AI for production planning generates dynamic production schedules based on historical data, current inventory levels, demand forecasts, and resource availability. Implementing AI to automate and optimize production schedules minimizes idle time, reduces bottlenecks, and ensures production aligns closely with real-time demand. Optimized production helps prevent product spoilage due to overproduction and ensures that you have sufficient stock to fulfil customer demands on time, improving customer satisfaction.

Real-time quality issue detection ensures product quality consistency, lowering product recalls

Using AI-powered sensors and computer vision, you can proactively monitor milk quality throughout the production process. AI in quality control prevents defective batches from being processed, ensuring consistent product standards and reducing rework or recalls. Real-time quality control reduces the likelihood of product recalls and financial losses, ensuring that product quality remains within regulatory parameters. This also helps you maintain consistent product quality, improving customer experience.

AI-based inventory storage monitoring for better stock rotation, prevents spoilage

AI in inventory management tracks stock levels, shelf life, and movement of raw materials and finished products using real-time data from IoT devices. Automated inventory management reduces spoilage, increases space utilisation, and ensures better stock rotation and replenishment planning. This reduces stockouts and overstocking, minimizing the chances of product spoilage and missed sales opportunities, which can ultimately lead to increased costs.

Equipment predictive maintenance to reduce unplanned downtime, prevent production delays

AI can detect early signs of equipment wear or failure by analyzing vibration, temperature, and usage data, reducing unplanned downtime, lowering repair costs, and enhancing equipment efficiency and reliability. This ensures that your production doesn’t halt and ensures timely order fulfillment, improving customer reliability.

Real-time milk batch tracking and traceability for quick recalls and to improve customer satisfaction

Integrating AI and blockchain can help you track every batch of milk from collection to final delivery, enhancing transparency, improving regulatory compliance, and speeding up recall processes if needed. This ensures consistent product quality and improves customer satisfaction.

AI-based energy optimization, ensuring energy-efficient operations, reduces cost

AI monitors and controls energy consumption across processing units, identifying patterns and suggesting optimization. This can help you reduce utility costs, support sustainability goals, and ensure energy-efficient operations. AI-based energy optimization can help you achieve sustainability and lower your operational costs.

Demand forecasting for accurate inventory management reduces product spoilage

Machine learning algorithms forecast customer demand by analyzing sales history, market trends, and external factors, enabling accurate production planning, reducing overproduction, and minimizing waste. This prevents stockouts and overstocking of products, ensuring optimal stock levels for timely order fulfillment.

Actionable insights to make real-time data-driven decisions, improve resilience

AI centralizes and processes data from various departments to provide actionable insights and automated decision-making, reducing response times, aligning operations with real-time conditions, and ensuring proactive business strategies. This enables your business to recover quickly from any disruption, reducing financial losses and strengthening resilience.

Where is AI used in the dairy supply chain?

AI is implemented across the dairy supply chain to automate operations, improve forecasting, and enhance decision-making. Here is how and where AI agents are integrated into different stages of the supply chain.

Forecasting procurement and production needs

AI production models can forecast future demand by analysing historical sales, market trends, seasonality, and external factors (such as weather or holidays). Artificial Intelligence production optimizes the amount of raw milk to be procured and processed, avoiding overproduction or shortage. Forecasting future demands reduces product spoilage chances and missed sales opportunities, reducing losses and improving profits.

Raw material planning based on past consumption

Machine learning algorithms study past consumption patterns of customers, packaging materials, additives, and energy usage. It suggests optimal reordering schedules and prevents stockouts or excess storage of perishable items, reducing wastes and financial losses due to missed sales opportunities.

Generating real-time KPI reports for management

AI aggregates operational data from multiple systems (production, inventory, logistics) to generate dashboards and performance reports. It provides management with real-time visibility into efficiency, yield, and downtime metrics for quicker decision-making. The ability to make real-time decisions empowers you to quickly respond to issues, preventing hefty losses and damage to the brand image.

Detecting Production drop trends (yield tracking)

AI monitors yield over time, spotting subtle decline or anomalies that humans may miss. This automated yield management helps identify issues such as equipment inefficiency, quality deviations in raw milk, or process bottlenecks. This enables you to track yield at every stage, ensuring minimum losses, enhancing production, and improving revenue.

Predictive maintenance for machines & equipment

AI uses sensor data (vibration, temperature, and noise) to predict when machines like homogenizers, chillers, and pasteurizers may fail. It automatically schedules maintenance before breakdown occurs, reducing downtime and repair costs and ensuring production continuity. This ensures reliable and timely deliveries, improving customer experience.

Customer support & complaint resolution bots

AI-powered chatbots and voice assistants handle customer enquiries, orders, and complaints across websites, apps, or messaging platforms. It delivers immediate responses, increases customer satisfaction, and reduces the support team’s efforts, particularly in direct-to-consumer dairy models.

AI agents used in the dairy industry

AI agents are intelligent systems that can autonomously monitor, analyze, and act on data to perform tasks, make decisions, and optimize processes. These agents are integrated across various operations to enhance productivity, quality, and efficiency. They are integrated with ERP systems such as Odoo, SAP, or Microsoft Dynamics Business Central. Here are the types of AI agents used in the dairy supply chain, categorized by module.

Milk collection & procurement module

AI Agents Used:

- Milk Quality Analysis Agent: Uses sensors and AI to assess fat content, SNF, and detect contaminants.

- Dynamic Pricing Agent: Suggests procurement prices based on quality, market rates, and volume trends.

- Farmer Yield Prediction Agent: Predicts expected milk quantity based on historical farm data.

Production and processing module

AI Agents Used:

- Production Planning Agent: Optimizes daily/weekly production schedules based on supply & forecast.

- Batch Monitoring Agent: Detects anomalies in pasteurization, homogenization, and cooling.

- Energy Optimization Agent: Minimizes energy usage by smartly controlling equipment cycles.

Quality control module

AI Agents Used:

- Vision-based Defect Detection Agent: Detects impurities or packaging errors using cameras.

- Real-time QC Agent: Monitors pH, temperature, and microbial levels using IoT sensors and AI.

- Compliance Audit Agent: Flags non-compliance and auto-generates QC reports.

Inventory management module

AI Agents Used:

- Expiry Tracking Agent: Tracks shelf life and prioritizes dispatch based on FEFO (First Expiry First Out).

- Stock Replenishment Agent: Predicts when stock needs to be reordered, avoiding overstocking/stockouts.

- Cold Storage Monitoring Agent: Maintains and adjusts optimal storage conditions in real-time.

Sales & order management module

AI Agents Used:

Demand Forecasting Agent: Predicts sales volume by geography, season, and customer behavior.

Order Recommendation Agent: Suggests promotions or upsells based on past orders.

Route Optimization Agent: Plans the most efficient delivery routes for perishable products.

Customer Relationship Management (CRM) Module

AI Agents Used:

AI Chatbot Agent: Answers queries, takes orders, and provides updates via WhatsApp, web, or app.

Customer Sentiment Analysis Agent: Analyzes feedback and reviews to identify areas of improvement.

Churn Prediction Agent: Flags customers likely to drop off based on usage or interaction trends.

Finance & accounting module

AI Agents Used:

- Invoice Matching Agent: Auto-verifies bills across delivery and purchase records.

- Fraud Detection Agent: Flags irregular transactions, overpayments, or inconsistencies.

- Cost Optimization Agent: Recommends areas to reduce overhead based on margin analysis.

Supply chain & distribution module

AI Agents Used:

- Logistics Forecasting Agent: Predicts delays or issues in the distribution network.

- Cold Chain Integrity Agent: Ensures temperature is maintained during transit via real-time tracking.

- Route Disruption Agent: Suggests alternative paths in case of traffic/weather disruptions.

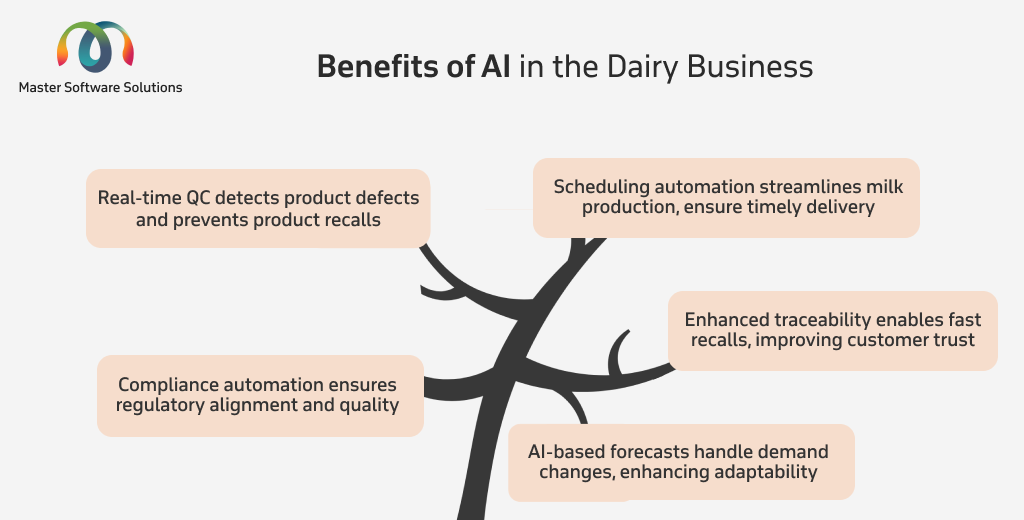

Benefits of AI in the dairy business

Artificial intelligence is transforming the dairy industry by automating critical processes, improving decision-making, and ensuring product quality and safety. Here are the key advantages AI offers across dairy operations

Real-time QC detects product defects and prevents product recalls

AI-powered sensors and computer vision systems continuously analyze milk parameters, including temperature, fat content, and microbial load during collection and processing. It immediately detects deviations in quality, preventing defective batches from progressing, reducing spoilage, and maintaining product integrity. This ensures delivering high-quality products, improving customer satisfaction and retention rates.

Scheduling automation streamlines milk production, ensure timely delivery

AI agents optimize processing schedules, monitor equipment performance, and automate routine handling tasks such as pasteurization timing, packaging, and cold storage transitions. This increases production efficiency, minimizes manual errors, and reduces energy, resource usage, and operational costs. Automating production schedules prevents overproduction or underproduction, mitigating the chances of stockouts and overstocking, which can lead to product spoilage and missed sales opportunities. This ultimately results in heavy financial losses.

Compliance automation ensures regulatory alignment and quality

AI for compliance helps businesses in meeting strict regulatory standards (FSSAI, ISO, HACCP) by tracking key quality metrics, automating reporting, and maintaining audit-ready records. Automated compliance reporting ensures consistent product quality, avoids penalties, and builds consumer trust through adherence to compliance protocols. This also ensures that you deliver quality products, improving customer satisfaction and brand image. Additionally, it helps minimize the chances of product recalls and returns.

Enhanced traceability enables fast recalls, improving customer trust

With AI integrated into blockchain and IoT systems, dairy businesses can trace each batch, recording every touchpoint in the supply chain. This enables quick and targeted product recalls, increases consumer confidence, and supports ethical and sustainable sourcing affirmations. This enhances customer satisfaction for those who are health-conscious and eager to know the origin of their products. Many large businesses, like Walmart, provide customers with a QR code on the product packet so they can see the entire journey of that product.

AI-based forecasts handle demand changes, enhancing adaptability

AI predicts demand, manages inventory, plans delivery routes, and schedules procurement, all in real time, reducing stockouts and overproduction, improving delivery efficiency, lowering operating costs, and enhancing responsiveness to market changes. This ultimately improves your customer satisfaction rates and ROI.

Conclusion

Integrating artificial intelligence in the dairy supply chain has become a competitive necessity. From accurate demand forecasting and optimized procurement to predictive maintenance and enhanced customer service, AI is transforming how dairy businesses operate, make decisions, and deliver consistent product quality.

Master Software Solutions provides comprehensive AI services to the dairy industry, including AI agent development, AI chatbot development, robotic process automation consultation, workflow automation services, and business process automation services. Let us help you automate your operations, improve efficiency, and unlock new levels of performance across your supply chain. Contact us today to explore how our AI solutions can transform your dairy business.