Coffee is the most consumed beverage, and the coffee supply chain is one of the complex supply chains for ERP software. It starts with growing and harvesting coffee beans, pulping, drying, distributing, roasting, packaging, dispatching, and delivering to customers (B2B and B2C). Efficiently managing such a complex supply chain requires a robust platform, such as an ERP software for the coffee industry.

This blog explores the coffee industry, the coffee supply chain, and ERP software for the coffee industry.

Table of contents:

Coffee industry – overview

The global coffee market size was estimated at USD 269.27 billion in 2024 and is projected to reach USD 369.46 billion by 2030, growing at a CAGR of 5.3% from 2025 to 2030. The coffee industry is a vast and complex market that includes the production, processing, distribution, and consumption of coffee. It is one of the most consumed beverages in the world. This industry is influenced by factors such as:

- Increasing demand for plant-based beverages

- Rising coffee culture

- Speciality and sustainably sourced coffee

Challenges faced in the coffee business without an ERP

Manually managing coffee businesses or using disparate systems is inefficient and can result in inaccurate data for inventory and production. This can lead to delays and customer dissatisfaction. The challenges coffee businesses face without an ERP are:

Manual production monitoring leads to inconsistencies in roasting profiles, reducing flavor, quality, and CSAT.

When production monitoring is done manually, there is a high risk of human errors in recording roasting times, temperatures, and bean quality. Even slight deviations in roasting profiles can impact flavor, changing the taste of batches from what customers expect. This leads to:

- The lack of consistency affects product quality and erodes customer trust and satisfaction (CSAT).

- Retailers and distributors may face increased complaints, returns, or reduced repeat purchases if coffee flavor varies from batch to batch.

- Without automated tracking, determining the root cause of production issues becomes difficult, resulting in reactive rather than proactive quality control.

Human-based quality checks are prone to errors, resulting in low-quality coffee, increased product recalls, and customer dissatisfaction.

Without an ERP system, many coffee businesses rely on manual, human-based inspections to maintain quality standards. While experienced staff can detect obvious defects, manual checks are inherently inconsistent and prone to oversight, especially when handling large volumes. These errors often lead to:

- Substandard coffee reaching the market increases the chances of product recalls or customer complaints.

- Product recalls result in financial losses due to wasted stock, increased logistics costs, and damage to brand reputation.

- Repeated encounters with inconsistent or poor-quality coffee lower satisfaction levels, impacting repeat sales and long-term loyalty.

- You can not proactively conduct quality checks, which makes you vulnerable to inefficiencies, compliance issues, and dissatisfaction.

Manually scheduling equipment maintenance could be flawed, resulting in inefficient energy usage and higher operational costs.

Coffee production relies heavily on specialized equipment, such as roasters, grinders, brewers, and packaging machines. To ensure smooth and efficient operations, this equipment requires timely maintenance. Maintenance schedules are manually recorded on spreadsheets, reminders, or operator memory, which can lead to mistakes and delays. This leads to:

- Inability to conduct timely maintenance may result in machines running inefficiently, consuming more energy than necessary, and increasing utility bills.

- Poor maintenance leads to unexpected breakdowns, production stoppages, and repair costs.

- Irregular maintenance shortens equipment lifespan, forcing businesses to make premature investments.

- An inefficient machine can compromise roasting precision or packaging quality. This leads to inconsistent products, increased waste, and dissatisfied customers.

Instinctive forecasting is prone to errors, resulting in overproduction or scarcity, product spoilage, or missed sales opportunities.

Accurate demand forecasting is important for balancing production, inventory, and distribution. Businesses rely on spreadsheets to plan supply, which often leads to inaccurate forecasting that fails to account for seasonal demand shifts, customer buying patterns, or market fluctuations.

When forecasting errors occur, two costly scenarios follow:

- Overproduction leads to excess stock, which increases storage costs and raises the risk of coffee beans or finished products going stale, causing spoilage and financial losses.

- Underproduction results in shortages, leaving distributors, retailers, and customers underserved. This not only creates missed sales opportunities but also drives customers towards competitors who can meet their demand.

Inconsistent forecasting also makes it difficult to streamline procurement of raw coffee beans, manage roasting schedules efficiently, or optimize distribution logistics. Over time, these inefficiencies hurt profitability, strain supplier relationships, and weaken customer trust.

No real-time production monitoring can delay responses to batch errors, shipping contaminated product, and increasing product recalls.

Maintaining consistency and safety across every batch is crucial. Businesses often lack real-time visibility into production processes, which means that errors such as incorrect roasting temperatures, contamination risks, or packaging defects are identified later in the cycle, sometimes after the product has already shipped. This results in:

- Delayed error detection puts both quality and safety at risk.

- Contaminated products reaching customers lead to widespread recalls, financial losses, and reputational damage.

- The lack of real-time visibility makes it difficult to identify the source of the problem.

- This also increases operational costs and weakens customer trust.

Manual mistakes in bean analysis before roasting result in over- or under-roasting, leading to inconsistent flavor scores and reducing customer satisfaction.

Coffee roasting is a precise process where the quality of beans must be carefully analyzed before roasting. Factors like bean size, moisture content, and origin determine the ideal roasting profile to achieve consistent flavor. Manual bean analysis is prone to errors, where the data can be miscalculated, overlooked, or inconsistently recorded. This directly affects the roasting process:

- Under-roasting can make the coffee taste flat or grassy, while over-roasting can produce bitter, burnt flavours.

- Inconsistent quality can damage the brand’s reputation.

- Replicating successful roasting profiles or identifying the cause of remedial action is challenging.

- Lack of control can lead to increased waste, limited scalability, and reduced market competitiveness.

Paper-based inventory tracking is prone to errors & may cause stockouts or overstocking, leading to dispatch delays, order cancellations & impacting ROI.

Businesses relying on paper-based tracking or a basic spreadsheet compromise accuracy and visibility. Manual records are vulnerable to miscounts, delays in updates, and misplaced data, making it difficult to track stock levels in real-time. This lack of accuracy creates two major risks:

- Stockouts occur when demand exceeds the recorded inventory, resulting in missed dispatch deadlines, canceled orders, and dissatisfied customers.

- Overstocking ties up capital in excess inventory, increases storage costs, and risks product spoilage, especially since coffee has a limited freshness cycle.

Dispatch delays and order cancellations weaken customer trust, while wasted or unsellable stock reduces ROI. Paper-based systems make it nearly impossible to track inventory across multiple warehouses or distribution points, further amplifying inefficiencies. Over time, these challenges can lead to poor demand planning, higher operational costs, and reduced market competitiveness.

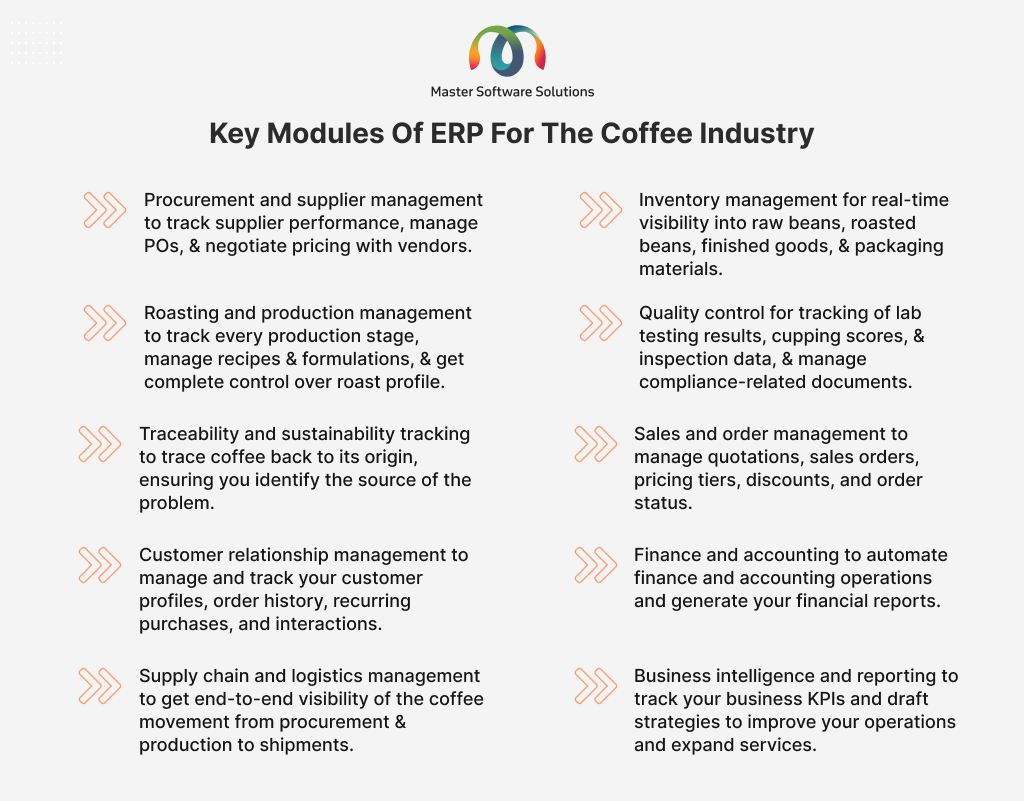

Key modules of ERP for the coffee industry

The enterprise resource planning system offers various modules that provide an end-to-end solution for your coffee business. The key ERP modules for the coffee industry are:

Procurement and supplier management to track supplier performance, manage POs, & negotiate pricing with vendors.

This module manages the sourcing of green coffee beans, flavoring ingredients, packaging materials, and equipment. You can track supplier performance, manage purchase orders, negotiate pricing, and ensure timely, high-quality raw material delivery. The system can also handle import documentation and certifications if beans are procured internationally.

Inventory management for real-time visibility into raw beans, roasted beans, finished goods, & packaging materials.

Effective inventory control is crucial to maintain the freshness of the product. It provides real-time visibility into raw beans, roasted beans, finished goods, and packaging materials. The system supports FIFO/ LIFO, expiry tracking, batch management, and automated reordering, minimizing waste and ensuring product quality.

Roasting and production management to track every production stage, manage recipes & formulations, & get complete control over roast profile.

This module provides complete control over roast profiles, batch sizes, and equipment scheduling. You can track every production stage, from roasting to grinding and packaging, while maintaining consistency, quality, and traceability. You can also manage recipes and track the production costs.

Quality control for tracking of lab testing results, cupping scores, & inspection data, & manage compliance-related documents.

ERP ensures that each batch meets flavor, aroma, moisture, and other quality parameters. You can track lab testing results, cupping scores, and inspection data. The system can isolate and flag the batch if it fails the quality check. You can maintain documents for audits, certifications, and food safety compliance in the system.

Traceability and sustainability tracking to trace coffee back to its origin, ensuring you identify the source of the problem.

The system enables you to trace coffee back to its origin, including the coffee farm, certifications, shipping history, production history, and production details. You use this information for labeling, ethical sourcing documentation, and customer trust-building.

Sales and order management to manage quotations, sales orders, pricing tiers, discounts, and order status.

This module consolidates sales, ordering, and fulfillment processes. You can manage quotations, sales orders, pricing tiers, discounts, and order status, ensuring timely order fulfillment and stock availability across all channels.

Customer relationship management to manage and track your customer profiles, order history, recurring purchases, and interactions.

You can manage customer profiles, order history, communications, and loyalty programs. You can also track the customer feedback, recurring purchases, and interactions across B2B and B2C clients. The system enables you to offer personalized marketing, retention strategies, and proactive service. This is specifically useful for subscription-based coffee services.

Finance and accounting to automate finance and accounting operations and generate your financial reports.

The ERP software for coffee businesses automates accounting operations, including billing, invoicing, tax calculations, bank reconciliation, and expense tracking. It can automatically generate financial reports, including cash flow and balance sheets, for budgeting, pricing decisions, and compliance with financial regulations.

Supply chain and logistics management to get end-to-end visibility of the coffee movement from procurement & production to shipments.

You can optimize delivery routes, transportation, and storage. This ensures that roasted coffee gets delivered quickly and fresh while coordinating bean import shipments and warehousing. It also helps reduce delivery costs and monitor third-party logistics.

Business intelligence and reporting to track your business KPIs and draft strategies to improve your operations and expand services.

Integrated ERP systems collect data from all departments and provide a dashboard, reports, and insights to aid decision-making. This can help you monitor sales performance, inventory health, customer trends, and operational costs, enabling you to make proactive, data-driven business decisions.

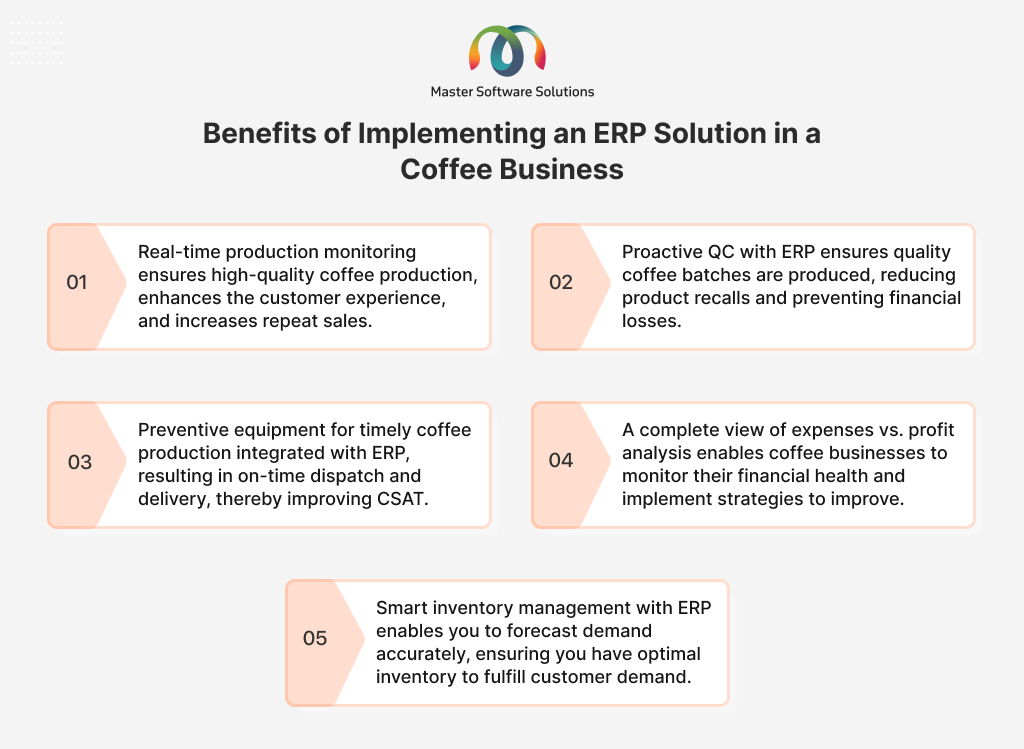

Benefits of implementing an ERP solution in a coffee business

The advanced features and functionalities of coffee ERP software streamline operations, ensuring data consistency and adherence to food safety regulations. The benefits of implementing an ERP solution in your coffee business are:

Real-time production monitoring ensures high-quality coffee production, enhances the customer experience, and increases repeat sales.

With ERP-enabled real-time production monitoring, coffee businesses can instantly track roasting and quality parameters, ensuring consistent flavor and minimizing. This results in higher product quality, happier customers, and increased customer loyalty. The benefits are:

- Maintains consistent quality – Tracking roasting temperature, batch times, and quality metrics in real-time prevents errors like over-roasting, ensuring a uniform flavor profile.

- Reduces waste and recalls – You can detect deviations immediately, allowing quick corrective action, minimizing defective batches, and reducing product losses and costs.

- Improves customer experience – It guarantees customers get the same taste and quality in every order, building trust and satisfaction, and leading to stronger brand loyalty.

- Boost repeat sales – Consistency in product quality encourages customers to repurchase, increasing long-term relationships with both retail and wholesale buyers.

- Enhances efficiency & profitability – It improves efficiency and profitability by providing managers with real-time insights that allow them to optimize production, reduce downtime, streamline operations, and increase overall profitability.

Proactive QC with ERP ensures quality coffee batches are produced, reducing product recalls and preventing financial losses.

Implementing an ERP solution equips coffee businesses with proactive quality control tools that go beyond manual checks. Automating inspections and tracking key parameters in real-time ensures only high-quality coffee batches reach customers. This reduces the risk of product recalls, prevents wastage, and protects profitability while strengthening customer trust. Key benefits are:

- Automated quality checks – Monitors roasting, grinding, and packaging against set standards to ensure product consistency.

- Early error detection – Identifies deviations in real-time, preventing defective batches from shipping.

- Reduced product recalls – Minimizes large-scale recalls, saving costs and protecting brand reputation.

- Financial protection – Prevents losses from wasted raw material, refunds, and rework.

- Customer trust & loyalty – Consistent high-quality coffee builds confidence, repeat purchases, and stronger brand loyalty.

Preventive equipment for timely coffee production integrated with ERP, resulting in on-time dispatch and delivery, thereby improving CSAT.

An ERP system helps coffee businesses automate and schedule preventive maintenance, ensuring machines like roasters, grinders, and packaging units run at peak efficiency. Reducing the risk of unexpected breakdowns ensures that production runs smoothly, and orders are processed and delivered on time. This consistent service reliability lowers operational costs and strengthens customer loyalty. Key advantages are:

- Automated maintenance scheduling – ERP tracks machine usage and schedules timely upkeep to avoid breakdowns.

- Consistent production flow – Prevents sudden downtime, ensuring roasting and packaging stay on schedule.

- On-time dispatch and delivery – Reliable equipment supports timely order fulfillment and smooth logistics.

- Cost savings – Reduces emergency repair costs and extends equipment lifespan.

- Higher customer satisfaction scores (CSAT) – Customer receive their orders in time, improving trust, repeat sales, and brand loyalty.

A complete view of expenses vs. profit analysis enables coffee businesses to monitor their financial health and implement strategies to improve.

An ERP system centralizes all financial data, covering procurement, production, distribution, and sales into a unified platform. With this complete visibility, coffee businesses can compare expenses against revenue in real-time, identify areas of overspending, and spot their most profitable products or customers. This transparency enables decision-makers to implement cost-cutting measures, fine-tune pricing strategies, and increase overall profitability while maintaining long-term financial stability. Key advantages are:

- Centralized financial data – Consolidates expenses, sales, and revenue streams for accurate analysis.

- Real-time profits vs. expense insights – Provides instant visibility into cash flow and profit margins.

- Informed decision-making – Identifies cost leaks and guides strategy for better resource allocation.

- Improved profitability – Helps refine pricing, reduce waste, and optimize investments.

- Sustainable business growth – Maintains financial health while supporting smarter long-term strategies.

Smart inventory management with ERP enables you to forecast demand accurately, ensuring you have optimal inventory to fulfill customer demand.

ERP can help businesses automate inventory management and align it with real-time demand data. Instead of relying on guesswork, ERP utilizes historical sales trends, seasonal demand patterns, and customer behavior for an accurate demand forecast. This ensures that the right amount of stock is always available, avoiding overstocking, which causes waste, and understocking, which leads to missed sales opportunities. This results in smoother operations, cost savings, and stronger customer satisfaction. The key advantages:

- Accurate demand forecasting – Utilizes data analytics to predict future demand based on sales trends and seasonality.

- Optimal inventory levels – Ensures you always have the right amount of stock to meet customer needs.

- Reduced wastage – Prevents overstocking that can cause beans or finished products to go stale.

- Improved order fulfillment – Minimizes stockouts, ensuring customers always get their orders on time.

- Higher profitability – Balances supply and demand effectively, cutting unnecessary costs and boosting sales.

How does Master Software Solutions help coffee businesses?

Master Software Solutions is an IT service-based company that offers ERP consulting services. Our ERP services include consulting, implementation, customization, integration, development, and migration. We work with Odoo erp, Microsoft Dynamics erp and Trakop delivery magnement software to provide your business with the right solution that aligns with your workflow.

Odoo

Odoo is an ERP platform that provides end-to-end solutions for your entire business. It contains interconnected modules, including procurement, inventory management, production management, quality control, sales management, finance and accounting, supply chain management, and distribution.

We offer Odoo consulting services, including implementation, migration, customization, consulting, integration, website development, module development, and support and maintenance.

Microsoft Dynamics

Microsoft Dynamics is an ERP platform powered by Microsoft. It offers advanced and robust features and functionalities for larger enterprises. It can help you optimize business operations, boost productivity, accelerate sales processes, and enhance customer experience.

We provide comprehensive Microsoft Dynamics 365 consulting services, including customization & integration, migration, CRM modernization, development and engineering, managed services, and business process consulting.

TrakOp

TrakOp, or Track Your Operations, is a subscription-based, scheduled delivery system. The system enables you to manage B2B and B2C businesses. It consists of an admin panel and mobile apps for the customers and drivers. TrakOp is our in-house project that focuses on helping subscription-based businesses, like dairy, bottled water, and coffee.

If you own a coffee business and would like to integrate ERP solutions into your operations, schedule a call, and a member of our team will contact you.