The dairy supply chain is one of the most intricate supply chains. It requires complete visibility and traceability to ensure that high-quality milk and dairy products reach the end consumers. Managing such a complex supply chain needs an advanced enterprise resource planning system to track and manage the entire dairy supply chain. ERP software for dairy manufacturers is a specialized enterprise system that automates and streamlines, providing real-time visibility and traceability. This blog article explores the dairy ERP system and examines how it can help you manage your operations, ensuring efficiency, productivity, regulatory compliance, and customer satisfaction.

This blog covers:

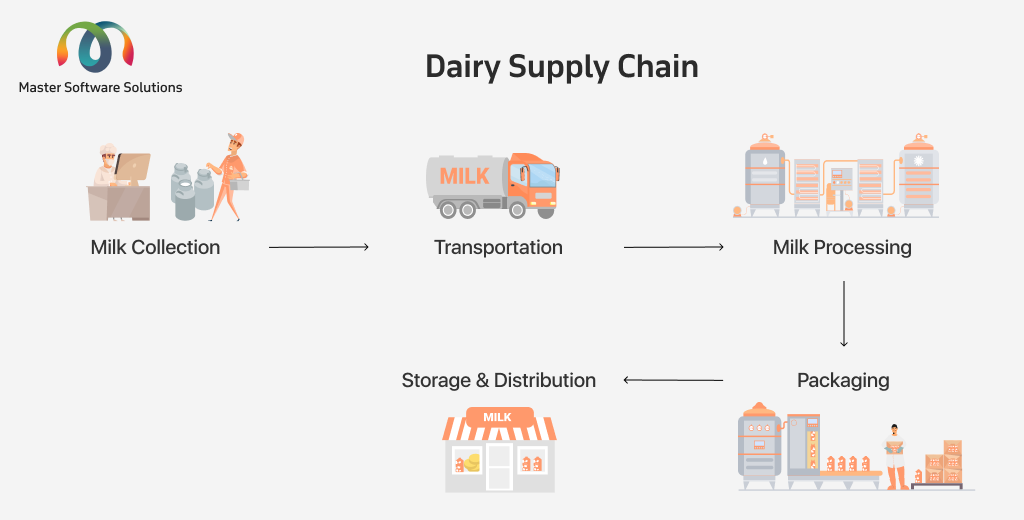

Understanding the dairy supply chain

In 2022, the dairy market value was estimated to be USD 893 billion and is anticipated to grow to USD 1,243 billion by 2028. The dairy supply chain contains the entire process of milk production, from farms delivering milk and dairy products to consumers. It involves multiple steps, including milk collection, processing, packaging, storage, and distribution, adding value at each step.

Milk collection

The dairy supply chain started at the dairy farms, where cows are milked. The milk is collected at milk collection centres, and the quality (SNF and fat) of milk from individual farmers is checked. The milk is collected in the bulk milk coolers (BMC).

Transportation

Milk collected from multiple milk collecting centres is transported to the milk processing plants via BMC-equipped trucks. Before the milk is collected, the quality is checked for each truck.

Milk processing

Once the quality of the milk is confirmed to be good, it is processed. Milk undergoes various processes, including pasteurization, homogenization, and cream separation, to produce other dairy products (butter, cheese, clarified milk, etc.). Based on these processes, various milk types (full-cream, skimmed milk, and low-fat) are created.

Packaging

After processing, dairy products are packed in various forms, including bottles, cartons, or bags. Packaging plays a crucial part in maintaining freshness and preventing contamination.

Storage & distribution

Milk and other dairy products are stored in refrigerated facilities to maintain their product quality. The distribution networks then deliver the products to retailers, supermarkets, and consumers.

What is a dairy ERP?

A dairy ERP system is a software platform that helps dairy businesses manage and integrate their core processes. The core processes in dairy ERP include milk collection or procurement, processing, quality control, inventory management, finances and accounting, delivery management, and customer relationship management.

The ERP system is a centralized platform that consolidates your entire business data, enabling you to track any updated information in real-time. Milk, being a perishable item and a daily morning necessity for most households, requires proactive supply chain monitoring to ensure high-quality products. The dairy ERP system aims to provide real-time visibility and traceability, allowing for easy product recall in the event of an issue.

Challenges dairy businesses face without an ERP system

Using multiple software solutions or manually operating dairy businesses can be tedious, inefficient, effort-consuming, costly, and flawed. You may relate to the below-mentioned challenges if you are managing your business manually or through multiple systems. The challenges dairy businesses face without ERP are:

Manual production planning leads to manual errors, misreporting quantities, quality, and processing delays.

It is impossible to manually track milk collection from multiple sources (farmers or cooperatives), making the process complex and error-prone. Manual data records can lead to misreporting quantities, quality inconsistencies, and processing delays. The lack of data centralization makes it difficult to align milk usage with the production needs, leading to overproduction or underutilization of resources.

Errors in inventory updates lead to stockouts/overstocking, delaying deliveries, & missing sales opportunities.

Dairy products have shorter shelf lives, making efficient inventory management crucial. Manual inventory management makes tracking perishable products across multiple storage locations, leading to spoilage, waste, or stockouts. Inaccurate inventory data can hinder production planning and timely order fulfillment, impacting profits and customer satisfaction.

Manual management limits supply chain visibility, leading to unnoticed disruptions, delays & increased costs.

Monitoring raw materials and finished products is impossible in the complex dairy supply chain with so many stakeholders (milk suppliers, cold logistics, retailers, and distributors). Manual management lacks transparency, leading to delays, increased delivery costs, and poor traceability during product recalls or quality audits.

Human-based compliance & quality checks are prone to errors & frequent recalls, leading to the delivery of low-quality milk and low CSAT.

The dairy industry is subject to strict and complex food safety and hygiene regulations. Maintaining inspection records, batch tracking, and quality checks manually is time-consuming and inconsistent.

Using multiple systems or manual operations can lead to human errors and inaccurate data, resulting in production and delivery issues.

Relying on fragmented systems or spreadsheets for production, finance, sales, and procurement results in data silos. The data is entered manually on multiple sheets or systems, leading to human errors, duplication, and wasted time.

Manually tracking finances is time-consuming and prone to errors, making cash flow unmanageable and impacting overall revenue.

Scaling your business operations, such as adding new products or expanding distribution channels, can become a bottleneck with manual systems. Managing higher-order volumes, more suppliers, or multiple plants without a centralized ERP system can result in operational chaos, missed selling opportunities, and poor customer service.

Disparate systems cannot adapt to growing data, resulting in operational chaos, missed opportunities, and poor service.

Building and maintaining relationships with retailers, distributors, and end consumers is inefficient with a manual system. It is challenging to handle pricing, discounts, complaints, and delivery schedules, which result in customer dissatisfaction and business loss.

Instinct-based forecasting is prone to inaccuracy, resulting in under- or over-production, missing selling opportunities, & wastage.

It is impossible to track business operations when managing manually or without a centralized system. Businesses are unable to track real-time inventory levels, sales trends, and production output. This makes it hard to forecast demand, plan production cycles, or adjust to market shifts, resulting in overproduction, waste, or lost sales.

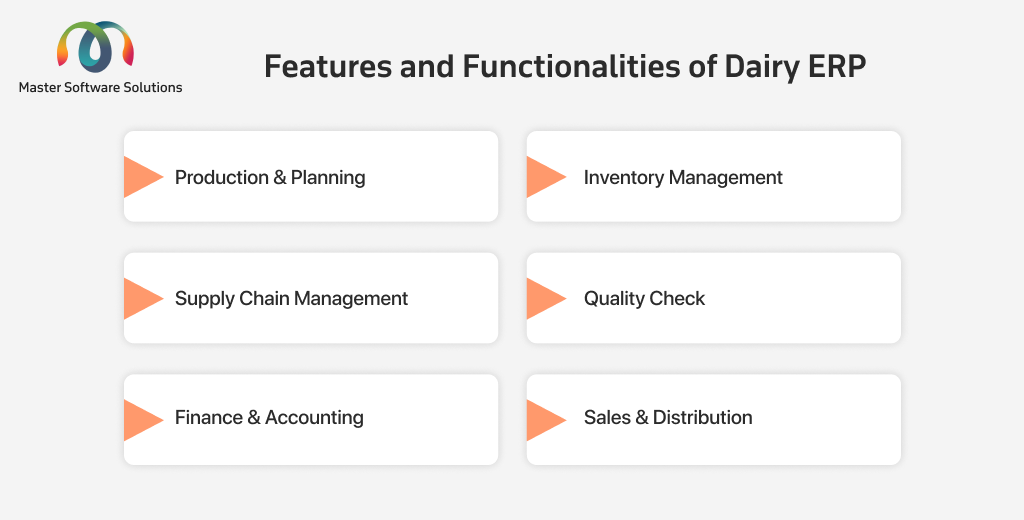

Features and functionalities of dairy ERP

Advanced ERP features and functionalities help B2B and B2C businesses simplify operations, increase efficiency, and improve customer satisfaction. They automate your entire dairy workflow from milk collection and processing to packaging and delivery. The features of the dairy ERP system are:

Production and planning for milk collection, production scheduling, milk utilization, & quality control.

Production planning plays an important role in the dairy industry due to its perishable nature. A dairy ERP system streamlines the entire production lifecycle, from procurement to processing and packaging. You can plan production based on customer demand, inventory levels, and supply availability. The system also allows you to track milk intake from multiple sources, capturing essential quality parameters such as SNF and fat content. You can automate scheduling and real-time production monitoring.

Inventory management to automate purchases, real-time reporting, Bill of Materials, & implement FIFO/FEFO.

ERP systems offer real-time visibility into raw materials, packaging items, and finished goods across warehouses and cold storage facilities. It empowers you to implement inventory management strategies such as FIFO (first-in, first-out) or LIFO (last-in, first-out), minimizing product spoilage. The system enables batch tracking, automates stock updates, and sends reorder alerts, ensuring that the products are always fresh and available without overstocking.

Supply chain management to track inventory, procurement, logistics, orders, warehouse, & supplier/vendor relationships.

The dairy supply chains involve various operations, such as milk collection, vendor procurement, cold storage logistics, and distribution. An ERP software integrates all these operations into a single platform, offering real-time visibility and enabling coordination between supply and demand. You can schedule milk collection routes, monitor transporter performance, and ensure timely deliveries. You can also track supplier deliveries, contract compliance, and inbound raw material.

Quality check to record and track milk quality (SNF/Fat), manage audit documents for FSSAI or ISO, & packaging check management.

The dairy industry requires adherence to strict food safety regulations. Complying with these strict regulations needs quality checks at various points, such as during milk collection, production, and packaging. You need to record key test results, like fat/SNF levels, bacterial counts, temperature, and acidity. The system allows you to record these tests and proactively monitor them. It can automatically isolate non-compliant batches and generate non-conformance reports. Additionally, it also helps you maintain audit-ready documentation for certification, such as FSSAI, ISO, or HACCP.

Finance & accounting to automate invoicing and financials data updates, timely farmer/vendor payments, & bank reconciliation.

A dairy ERP software integrates finance and accounting across procurement, production, inventory, and sales. This provides the finance team with a real-time view of business expenses and payments. It automates invoicing, payment collection, vendor payments, and expense tracking. The system can easily generate a profit and loss statement, balance sheets, and cash flow reports with accurate and up-to-date data.

Sales & distribution for timely subscription & one-time order processing, delivery planning, & route optimization.

Dairy products must be delivered quickly and efficiently. The system allows you to manage sales orders from retailers, wholesalers, and direct consumers. It supports dynamic pricing, promotional offers, and discount structures. You can assign delivery routes and schedules to the field agents with real-time tracking of dispatch and returned goods. Offering mobile access to the delivery person enables them to update order status and collect digital payments.

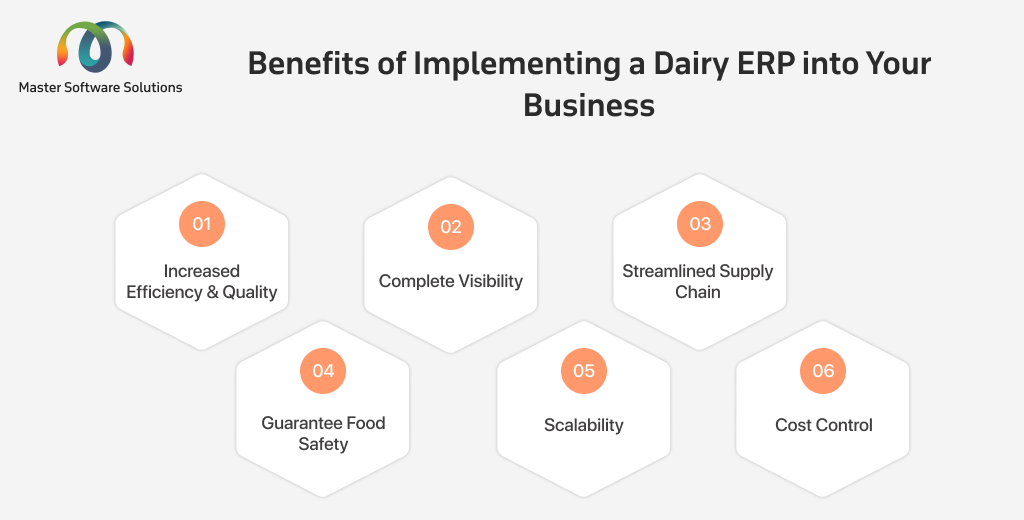

Benefits of implementing a dairy ERP into your business

The dairy ERP system’s comprehensive features and functionalities automate operational workflow and improve efficiency and customer satisfaction. The benefits of implementing a dairy ERP into your business are:

Real-time quality checks prevent frequent product recalls, ensuring high-quality products are delivered & improving customer experience.

In the dairy industry, even a minor lapse can lead to product contamination, costly recalls, and loss of customer trust. A dairy ERP integrates real-time quality checks directly into the production processes, ensuring that every stage, from milk collection and pasteurization to packaging, is monitored and recorded.

- Prevents frequent recalls – Automated checks reduce human errors and quickly flag quality issues before the product leaves the facility.

- Maintain compliance – Continuous monitoring ensures adherence to food safety standards and regulatory requirements.

- Deliver high-quality products – Catching issues early ensures that only safe and consistent products reach the market.

- Improve customer experience – Reliable quality builds trust, strengthens brand reputation, and fosters customer loyalty.

Production planning and scheduling streamline milk production, ensuring timely and accurate manufacturing.

Implementing a dairy ERP aligns raw material availability, processing capacity, and customer demand, streamlining production planning and scheduling. The system automates production schedules, ensuring that milk and dairy products are manufactured at the right time, in the right quantity, and with consistent quality.

- Timely production – Automates planning to meet daily demand without delays.

- Accurate manufacturing – Reduces errors in batch sizes and product variations.

- Resource optimization – Ensures equipment, labor, and raw milk are utilized efficiently.

- Reduced wastage – Minimizes overproduction and spoilage through demand-driven schedules.

- Higher customer satisfaction – Consistent and on-time deliveries build stronger trust with distributors and retailers.

Digitalized compliance ensures all your documents are stored in one place for seamless audits.

Complying with food safety and regulatory standards is critical for dairy businesses. Managing this manually often leads to misplaced documents, human errors, and stressful audits. The dairy ERP software digitizes all the compliance processes. All certifications, quality resorts, inspection logs, and regulatory documents are stored in a centralized digital repository. This ensures:

- Easy access – Auditors and managers can quickly retrieve required documents without the hassle of searching for paperwork.

- Accuracy – Automates recordkeeping, reduces human errors, and ensures all data is up-to-date.

- Time savings – Audits become faster and smoother with organized, searchable records.

- Risk reduction – Minimizes the chances of non-compliance penalties and strengthens trust with customers and regulators.

Digitalizing compliance management with dairy ERP simplifies audits and fosters operational transparency, protecting the brand’s credibility in a highly regulated market.

Automating finances and accounting enables you to track all transactions and analyze profit vs. expense for improved cash flow.

An ERP for the dairy business automates the entire accounting process, from recording transactions to generating financial statements, ensuring accuracy and efficiency. With ERP, every sale, purchase, and expense is tracked in real-time and consolidated in a centralized ledger. This enables business owners and managers to easily compare profit vs. costs, identify areas of overspending, and optimize resource allocation. Automated invoicing, payables, and receivables also reduce payment delays, strengthening overall cash flow. Key outcomes:

- Clear visibility into profitability at all times.

- Reduced errors and compliance risks.

- Faster financial decision-making with real-time insights.

- Improved cash flow through streamlined collections and payments.

Offering a personalized customer experience fosters stronger relationships, which increase repeat sales and retention rates.

A dairy ERP allows businesses to capture and analyze detailed customer data, including purchase history, delivery schedules, payment preferences, and product choices. With this centralized visibility, dairy businesses can personalize services, for example, offering tailored promotions, flexible delivery plans, or subscription models that fit each customer’s needs.

- Stronger relationships – Customers feel valued when services align with their preferences.

- Higher retention rates – A seamless and personalized experience reduces churn.

- Repeat sales growth – Satisfied customers are more likely to reorder regularly and even increase order volumes.

Delivering personalized customer experiences through ERP, dairy businesses not only improve customer satisfaction but also create long-term loyalty that fuels sustainable revenue growth.

Optimized inventory management ensures you have optimal stock to fulfill customer demand and not miss selling opportunities.

Overstocking leads to spoilage and wasted costs, while understocking results in missed sales and dissatisfied customers. An ERP system solves this by providing real-time visibility into stock levels across warehouses, production units, and distribution points. It tracks raw milk, processes products, and packages materials, ensuring you always know what needs replenishment. With demand forecasting and automated reordering, ERP helps maintain the right stock levels without overburdening storage. Impact on business:

- Prevents product wastage due to over-production.

- Ensures timely product availability to meet customer demand.

- Reduces storage costs and improves cash flow.

- Enhances customer satisfaction and trust by ensuring on-time delivery.

Partner with Master Software Solution for efficient dairy ERP implementation

Master Software Solutions is an IT service provider that offers ERP consulting services, including customizations, integrations, implementation, development, and migration from legacy systems for the dairy industry. We have experienced ERP professionals who work on ERP platforms such as Odoo and Microsoft Dynamics 365 to provide you with tailored solutions.

Odoo

Odoo is a comprehensive ERP system for small and medium-sized businesses to automate and streamline their operations. It consists of multiple business management applications, including purchase, inventory, sales, CRM, supply chain management, manufacturing, finance and accounting, quality checks, and delivery.

Microsoft Dynamics 365

Microsoft Dynamics 365 is an end-to-end platform for larger dairy enterprises to consolidate their operations, improving efficiency, productivity, and profitability while reducing overheads. It includes management modules such as inventory management, customer relationship management, supply chain management, manufacturing management, quality checks, and delivery.

TrakOp

TrakOp is a subscription-based scheduled delivery system for dairy startups to manage and track their orders, inventory, finances, delivery planning, route optimization, customer management, and reporting. This is our in-house product, specifically designed for dairy businesses that offer milk and dairy products as subscription products.

If you are a dairy business owner and want to implement ERP solutions in your business, schedule a call with us.