The dairy industry operates in a uniquely demanding environment where efficiency, quality, and speed are crucial for success. From managing perishable raw materials and ensuring product quality to maintaining compliance and controlling operational costs, dairy businesses face complex challenges daily. With increased competition and evolving consumer demands, legacy systems are no longer effective.

A report suggests that 66% of organizations that implement ERP systems said their ERP systems have improved the efficiency of their operations.

This is where enterprise resource planning platforms come in. Many ERP implementation companies, such as Master Software Solutions, have customized ERP platforms, like Odoo or Microsoft Dynamics 365 Business Central, to meet the specific needs of dairy businesses.

This blog explores how ERP implementation can enhance efficiency in the dairy value chain, enabling dairy businesses to operate more profitably and competitively in an increasingly digital market.

Table of Contents

Understanding the ERP system in the context of the dairy industry

An enterprise resource planning (ERP) system is an integrated software platform designed to unify and streamline core business processes across an organization. In the context of the dairy industry, ERP addresses the sector’s unique operational complexities, including handling perishable raw materials, managing quality variations in milk, and maintaining strict regulatory compliance.

The dairy-focused ERP systems are tailored to manage end-to-end operations, from milk procurement at collecting centers to processing, packaging, distribution, and financial reconciliation. The system provides dairy businesses with:

- Real-time data capture in milk quantity, quality parameters, pricing, and farmer payments.

- Production planning, batch tracking, inventory and cold chain management, quality control, and traceability.

- Real-time visibility and actionable insights.

A dairy ERP software is a foundational technology that enables operational efficiency and scalable growth in modern dairy enterprises. The system:

- Ensures transparency and accuracy at the procurement stage.

- Eliminates data silos and manual interventions that can lead to inefficiencies and errors.

- Enables businesses to respond quickly to demand fluctuations, reduce waste, Optimize costs, and ensure consistent product quality.

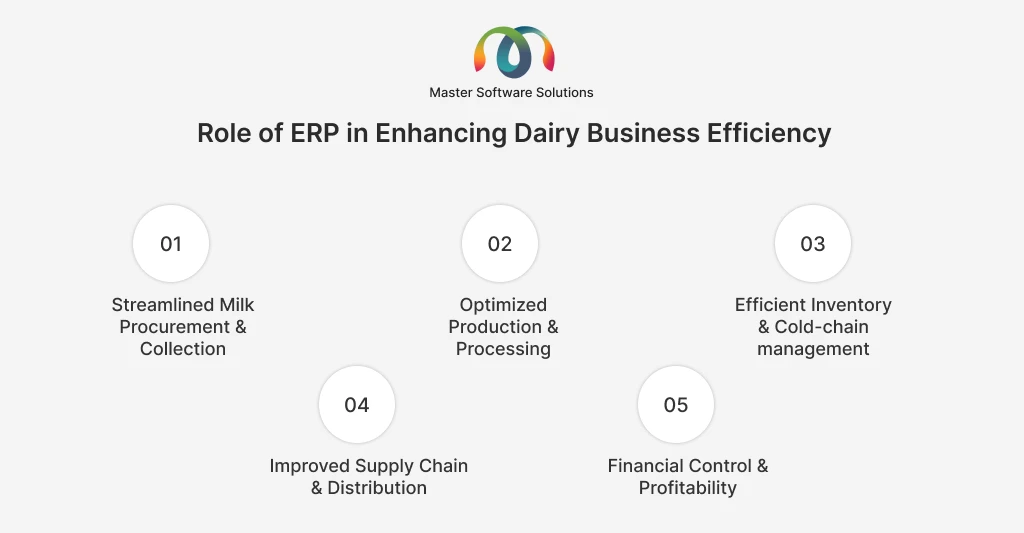

Role of ERP in enhancing dairy business efficiency

ERP software for the dairy industry plays a crucial role in improving operational efficiency across the entire dairy value chain. The system integrates procurement, production, inventory, logistics, and finance into a unified digital platform. This enables businesses to operate with greater efficiency, transparency, and control. Below is a detailed explanation of how ERP enhances efficiency in key functional areas of a dairy business.

Streamlined milk procurement and collection

Milk procurement is the foundation of dairy operations and one of the most complex processes, due to variations in quality, daily volume fluctuations, and payment structures of farmers. An ERP system digitizes and standardizes milk collection processes. It can capture real-time data at milk collecting centers, including quantity, fat and SNF content, and quality test results.

The ERP system automates farmer management, payment calculations, incentives, and deductions, reducing manual errors and payment delays. Real-time visibility into procurement volumes and quality trends helps dairy businesses to better plan production, strengthen farmer relationships, and ensure consistent raw material supply.

Optimized production and processing

In dairy processing, efficiency depends on precise production planning, yield optimization, and minimal losses. ERP systems support batch-wise production management, recipe formulation, and real-time monitoring of processing activities. The system enables dairy manufacturers to track input-to-output ratios, identify losses at each stage, and improve overall yield.

Production planning modules within a dairy ERP system help align milk availability with demand forecasts, ensuring optimal capacity utilization and reducing downtime. ERP also supports quality checks at each production stage, ensuring consistency in taste, texture, and safety while minimizing rework and wastage.

Efficient inventory and cold-chain management

Managing perishable dairy inventory is a major challenge in the dairy industry. ERP systems provide real-time visibility into inventory levels across raw materials, work-in-progress, and finished goods. They track batch numbers, expiry dates, and shelf life, enabling First-Expiry-First-Out (FIFO) inventory management to reduce spoilage and wastage.

ERP also supports cold-chain management by monitoring storage conditions and inventory movement across warehouses and distribution points. Maintaining accurate stock data and automating replenishment planning in dairy businesses helps avoid stock-outs, reduce overstocking, and ensure product freshness throughout the supply chain.

Improved supply chain and distribution

ERP systems enhance supply chain efficiency by integrating demand forecasting, order management, logistics, and distributor operations. ERP also facilitates distributor and retailer management by providing visibility into orders, returns, and receivables, resulting in better service levels and stronger channel relationships.

Financial control and profitability

ERP brings financial discipline and transparency to dairy operations by integrating accounting, costing, and financial reporting with operational data. It enables real-time tracking of procurement costs, production expenses, logistics costs, and overheads, providing a clear view of profitability at product, plant, and channel levels.

Automated financial processes, including invoicing, payments, reconciliations, and statutory reporting, reduce manual effort and errors. With accurate and timely financial insights, management can identify cost leakages, improve margin control, and make informed decisions. Ultimately, ERP dairy helps dairy businesses achieve sustainable profitability while supporting scalable growth.

Compliance, quality, & traceability

Compliance, quality assurance, and traceability are critical pillars of dairy operations due to strict food safety regulations, high consumer sensitivity, and the perishable nature of dairy products. An ERP system enables businesses to meet regulatory standards, maintain product quality, and achieve end-to-end traceability across the supply chain. Ways ERP helps with compliance, quality, and traceability:

Regulatory compliance management

Dairy businesses must comply with multiple local and international regulations related to food safety, hygiene, labeling, and environmental standards. ERP systems embed regulatory requirements directly into operational workflows, automating compliance. This includes maintaining mandatory records for milk procurement, processing, storage, and distribution, as well as generating audit-ready reports for regulatory authorities.

ERP also supports compliance with standards such as FSSAI, ISO, HACCP, and other food safety frameworks. It ensures proper documentation, approval workflows, and process controls. Automating alerts and validations helps mitigate the risks of non-compliance, penalties, or operational disruptions.

Quality control and assurance

Maintaining consistent product quality improves brand reputation and consumer trust. ERP systems enable quality management at every stage of dairy operations, from raw milk collection to product dispatch. Quality parameters such as fat, SNF levels, microbial counts, and temperature readings can be recorded, monitored, and analyzed in real time.

The dairy ERP solutions facilitate batch-wise quality testing, deviation tracking, and strategy management. Integrating quality data with procurement and production processes enables businesses to quickly identify quality issues, minimize rejections, and ensure that only compliant products move forward through the supply chain.

End-to-end traceability

Traceability is crucial for managing product recalls, addressing quality complaints, and ensuring transparency across the dairy value chain. ERP systems link raw milk sources, processing batches, storage locations, and distribution channels, providing complete batch and lot traceability within a single platform.

In the case of a quality issue or recall, ERP enables rapid identification of affected batches and their distribution points, significantly reducing response time and potential financial loss. This level of traceability not only protects consumers but also strengthens regulatory confidence and brand credibility.

Risk mitigation and recall readiness

Integrating compliance, quality, and traceability into a unified ERP platform, dairy businesses can proactively manage risks rather than react to issues after they occur. Real-time monitoring, automated alerts, and comprehensive audit trails ensure recall readiness and operational resilience.

Overall, ERP systems provide the structure, visibility, and control to maintain high standards of safety and quality while ensuring that regulatory requirements are efficiently and consistently met.

Also Read: Odoo for Dairy Manufacturing: Revolutionizing the Dairy Industry

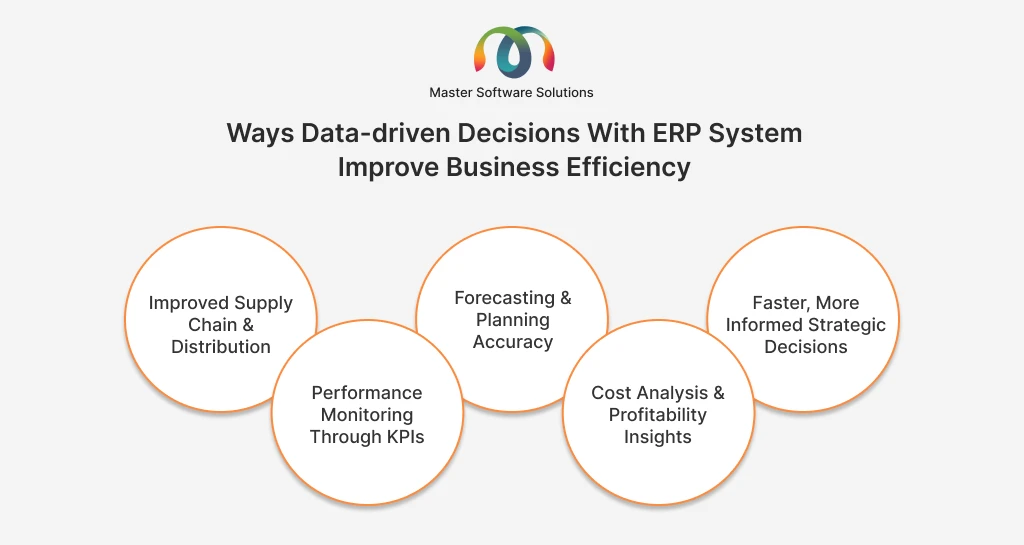

Data-driven decision-making with ERP

In the dairy industry, margins are tight and operational variables change daily, making timely and accurate decision-making crucial. An ERP system consolidates data from procurement, production, quality, inventory, distribution, and finance into a single platform. This integrated data environment enables dairy businesses to move from institution-based decisions to data-driven, strategic decision-making. Ways data-driven decisions with ERP for the dairy industry improve business efficiency.

Real-time visibility across operations

ERP software for the dairy industry provides real-time dashboards and reports. They offer real-time visibility into key operational metrics, including milk procurement volumes, quality parameters, production yields, inventory levels, sales performance, and financial status. Decision-makers can monitor as they happen, quickly identify deviations, and take corrective action before issues escalate. This real-time insight is particularly valuable in managing perishable products and fluctuating demand.

Performance monitoring through KPIs

The dairy ERP enables the definition and tracking of key performance indicators (KPIs) specific to dairy operations, such as milk yield variance, processing losses, spoilage rates, on-time delivery performance, and product-wise margins. Continuous monitoring of these KPIs enables management to assess operational efficiency, benchmark performance across plants or collection centers, and drive continuous improvement initiatives.

Forecasting and planning accuracy

The dairy ERP software utilizes historical data and trend analysis to forecast demand and plan production. This helps businesses align milk procurement, processing schedules, and distribution plans with actual market demand. Improved forecasting reduces overproduction, minimizes wastage, and ensures optimal utilization of processing and cold storage capacity.

Cost analysis and profitability insights

ERP integrates operational data with financial information, enabling detailed cost analysis across procurement, production logistics, and sales. Management can evaluate profitability at the product, customer, region, or channel level. These insights support informed pricing decisions, cost optimization strategies, and investment planning.

Faster, more informed strategic decisions

The dairy ERP system provides accurate, timely, and actionable insights, reducing decision-making cycles and improving responsiveness to market changes. Whether it is adjusting procurement strategies based on quality trends, reallocating inventory to high-demand regions, or launching new products, the ERP software empowers dairy businesses to make data-based decisions.

Conclusion

In an industry where operational efficiency, product quality, and regulatory compliance impact profitability, ERP implementation has become a strategic investment. Integrating milk procurement, production, inventory, cold-chain management, supply chain operations, finance, and quality control into a unified system enables complete visibility and tighter control across the dairy value chain. This reduces waste, improves productivity, supports compliance, ensures data-driven decision-making, and supports sustainable growth.

If you are looking to improve efficiency, enhance traceability, and gain better control over your dairy operations, now is the time to invest in ERP implementation. Master Software Solutions provides customized ERP solutions tailored to cater to the unique demands of dairy businesses. Contact us to discuss your dairy business.