Metal fabrication and job shops deal with more complex processes, including quoting custom jobs, managing raw material, scheduling machines, tracking labor hours, and meeting tight delivery deadlines. Shops also struggle with inaccurate job costing, excess scrap, poor visibility of work-in-progress, and constant rescheduling when priorities shift.

Without metal fabrication ERP software, these tasks often become disjointed, leading to disruptions, costly errors, and missed opportunities. Manual spreadsheets and disconnected tools can’t keep up with the constant change in orders, materials, and production schedules.

This blog examines the unique challenges that metal fabrication shops and job shops face when operating without an ERP.

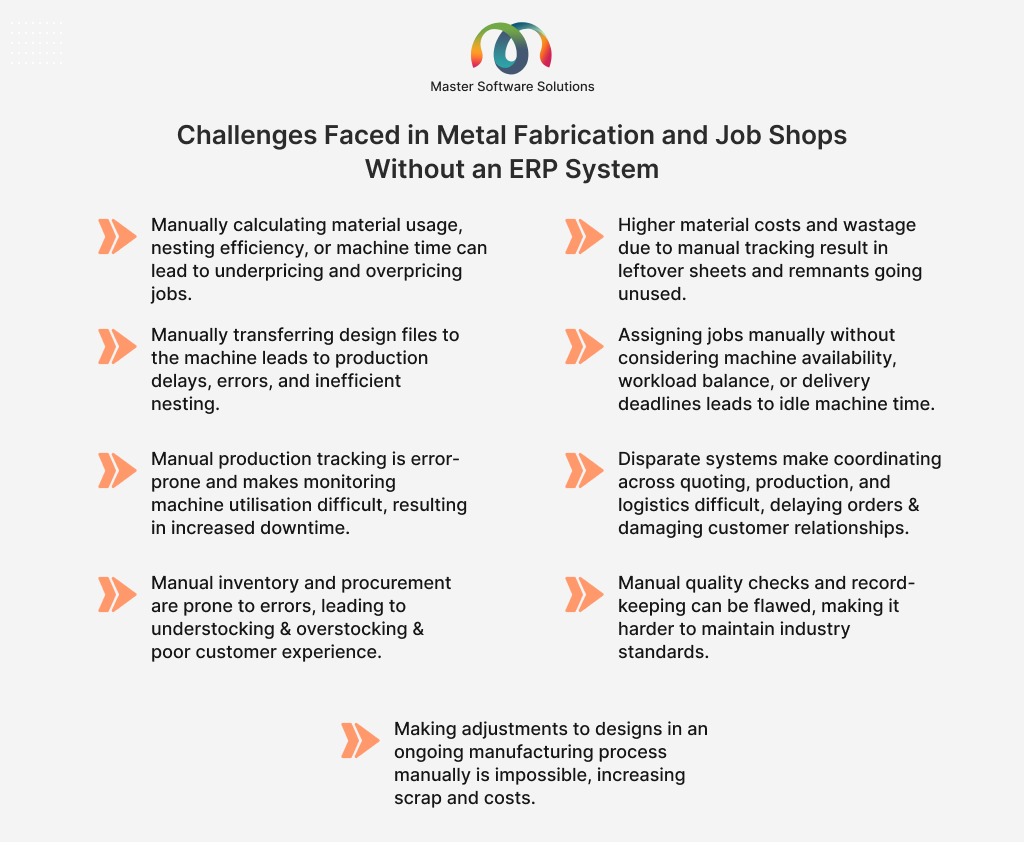

Challenges Faced in Metal Fabrication and Job Shops Without an ERP System

Metal fabrication and job shops rely on precision, speed, and cost control to ensure timely deliveries without compromising quality. From inaccurate quoting and excessive material waste to poor visibility across projects and constant production delays, the absence of an integrated system often leaves businesses relying on spreadsheets, manual entries, or disconnected software. Here are the common challenges metal fabrication and job shops face:

Manual batch & sub-batch management makes tracking material & defect detection difficult, leading to material losses & higher rework & scrap costs.

Manual batch and sub-batch management make it extremely difficult for fabricators to accurately track materials across the shop floor and detect them at the right stage. Since records are maintained in spreadsheets or on paper, the flow of raw material into sub-batches gets lost, and identifying which sub-batch carries defects becomes nearly impossible. This lack of visibility not only leads to unnecessary material losses but also increases rework and scrap rates, raising overall production costs and delaying deliveries.

Capturing, linking, and carrying heating numbers & MTRs through operations manually leads to errors, lost traceability, and audit risks.

Heat numbers and Mill Test Reports (MTRs) are critical for ensuring material traceability and compliance in industries such as aerospace, automotive, and oil & gas. However, when these are captured, linked, and carried forward manually through receiving, inventory, production, and shipping, errors and document mismatches become inevitable. Lost or misfiled MTRs disrupt the traceability chain, making it difficult to prove material compliance during audits or when responding to customer requirements. This not only increases compliance risks but also undermines customer confidence and exposes the business to audit failures.

Tariff-driven price fluctuations make bulk repricing error-prone, causing revenue loss, compliance risks, & customer disputes.

Tariffs force companies to quickly update bulk product prices, raw material costs, and customer orders due to the frequent and unpredictable changes in the cost of raw materials and completed goods. When handled manually, repricing at scale becomes highly prone to errors, leading to inconsistencies between quotes, invoices, and contracts. Such errors result in revenue leakage if increased costs are not passed on, compliance risks when prices deviate from agreed terms, and customer disputes that damage long-term relationships. For many fabricators, this makes managing profitability and trust an ongoing challenge.

Manually calculating material usage, nesting efficiency, or machine time can lead to underpricing and overpricing jobs.

In metal fabrication and job shops, every project is unique, requiring different materials, machine time, and labor hours. Without an ERP for the fabrication industry, job shops rely on spreadsheets or manual calculations to estimate costs for material usage, nesting efficiency, and machine runtime. This manual process is highly prone to errors and time-consuming.

For example, when calculating material requirements, failing to optimize nesting (the arrangement of parts on a sheet of metal) may lead to overestimating scrap, driving quotes higher than necessary. On the other hand, underestimating material waste or machine time can result in underpricing jobs, where the shop ends up spending more on production than it earns from the customers. Both these situations hurt profitability; overpricing customers drives customers away, while underpricing erodes margins and long-term sustainability.

Higher material costs and wastage due to manual tracking result in leftover sheets and remnants going unused.

In metal fabrication and job shops, raw materials such as steel, aluminium, or copper sheets account for a large portion of overall project costs. Efficient usage and accurate tracking of these materials directly impact profitability. However, without an ERP system, most shops depend on manual tracking methods, including spreadsheets, paper records, or operator memory, which are prone to errors and inconsistencies.

This often results in ineffective management of leftover sheets and remnants. For example, when a sheet is partially used for one project, the remaining piece may not be logged correctly or easily retrievable for future jobs. As a result, remnants sit unused in storage, while new sheets are ordered unnecessarily. Over time, this can result in increased material waste, working capital constraints, and excess inventory.

Additionally, without automated nesting and real-time visibility into available stock, shops struggle to optimize sheet usage across multiple projects. Poor nesting efficiency and mismanaged remnants mean higher scrap rates, escalating material costs, and slimmer margins. Ultimately, this lack of control makes it difficult for fabrication and job shops to stay competitive, especially when material prices fluctuate.

Manually transferring design files to the machine leads to production delays, errors, and inefficient nesting.

The fabrication and job shops heavily rely on the smooth transfer of design files, such as CAD drawings or CAM programs, to the machines on the shop floor. Without metal fabrication ERP software, this process is often done manually, using USB drives, emails, or printed drawings. While it may seem manageable, manual file handling introduces significant risks and inefficiencies.

Every manual step increases the likelihood of errors, such as loading the incorrect file version, transferring incomplete data, or using outdated designs for laser cutting and metal fabrication. These errors result in scrapped parts, rework, and wasted material, all of which drive costs and slow down delivery schedules.

Manual transfers also cause production delays. Operators may spend valuable time locating the right file, double-checking specifications, or waiting for updated instructions from engineering. Inefficient nesting becomes another issue; without integrated software, machine operators may not optimize how parts fit on a sheet, resulting in excessive scrap and higher material usage.

In a competitive fabrication environment, these inefficiencies quickly accumulate, causing shop floor disruptions, reducing throughput, and making it difficult to meet customer deadlines. An ERP system integrated with CAD/CAM nesting software for laser cutting streamlines this process by automating the file transfer, ensuring the right design reaches the right machine at the right time, while also improving nesting efficiency.

Assigning jobs manually without considering machine availability, workload balance, or delivery deadlines leads to idle machine time.

Assigning jobs to the machines is a critical step that directly impacts throughput and delivery timelines. Without an ERP system, this scheduling is often handled manually through spreadsheets, whiteboards, or verbal instructions. While simple in theory, manual job assignment overlooks key factors, like machine availability, operator capacity, workload distribution, and customer deadlines.

This results in your machines sitting idly while others are overloaded with back-to-back jobs. For example, one laser cutting machine may have no scheduled workday due to poor visibility of capacity, while another runs overtime to catch up on delayed orders. This imbalance leads to production disruptions, missed deadlines, and inefficient resource utilization.

Manual scheduling also makes it difficult to adapt when priorities change, such as urgent orders, machine breakdowns, or shortages. Reassigning jobs often requires reshuffling schedules on the fly, which introduces errors and further delays. Over time, these inefficiencies reduce overall equipment effectiveness (OEE), increase operating costs, and lower customer satisfaction due to late deliveries.

Manual production tracking is error-prone and makes monitoring machine utilisation difficult, resulting in increased downtime.

Monitoring production progress and machine utilization is critical to meeting deadlines, maximizing efficiency, and controlling costs. Without ERP software, production tracking is often manual, including relying on paper logs, spreadsheets, or verbal updates from operators. This approach is highly error-prone and provides little real-time visibility into the shop floor.

Manual tracking makes it difficult to know which machines are running, which jobs are in progress, and how long each task takes. This enables production managers to identify issues, balance workloads, or optimize machine schedules. Machines may sit idle due to miscommunication or delays in updating job status, while other equipment is overloaded.

These inefficiencies result in increased downtime, missed deadlines, and poor overall equipment performance (OEE). Without accurate data, managers cannot make informed decisions to improve productivity or prevent delays, which ultimately affects delivery timelines and profitability.

Disparate systems make coordinating across quoting, production, and logistics difficult, delaying orders & damaging customer relationships.

Job shops offer metal fabrication, bench pressing, tube cutting, and welding, and rely on tight coordination between quoting, production, and logistics to deliver custom orders on time. Without an integrated ERP, bending and welding job shops waste time juggling quotes in spreadsheets, scheduling production in disconnected software, and tracking logistics with manual logs. This fragmentation creates data silos, making it difficult to share accurate information across departments.

For example, the sales team might provide a quote without realizing the current workload on machines or the availability of materials. Production teams may start jobs without clarity on delivery deadlines, while logistics may not be aware of the schedule changes until it is too late. This lack of synchronization delays orders, causes last-minute rescheduling, and execution errors.

The consequences are significant. Late deliveries and inaccurate commitments damage customer trust, reduce repeat business, and harm the shop’s reputation. Additionally, staff spend extra time reconciling data between systems, which reduces efficiency and increases the risk of human errors.

Manual inventory and procurement are prone to errors, leading to understocking & overstocking & poor customer experience.

Metal fabrication and job shops utilize raw materials such as steel, aluminium, and specialty alloys, which are essential for completing jobs on time and within budget. Without an ERP system, inventory and procurement are often managed manually, using spreadsheets, paper logs, or separate procurement software. This manual approach is highly error-prone and can easily lead to understocking, overstocking, or mismanaged materials.

Understocking occurs when materials run out unexpectedly, production delays occur, or urgent, costly purchases are required to meet deadlines. Overstocking, on the other hand, ties up capital in unused inventory and increases storage costs, while older material may become obsolete or unstable. Both scenarios directly affect operational efficiency and customer satisfaction, as delays or compromised quality can result in missed delivery dates and frustrated clients.

Manual tracking also makes it difficult to maintain visibility of stock across multiple warehouses or shop locations. This lack of real-time information prevents production planners from efficiently scheduling jobs or optimizing material usage. Ultimately, errors in inventory and procurement reduce profitability, increase waste, and negatively impact the customer experience.

With an ERP system, inventory is tracked in real-time, procurement is automated, and alerts can be set for low stock or expiring materials. This ensures the right materials are available at the right time, reducing errors, improving efficiency, and enhancing customer satisfaction.

Manual quality checks and record-keeping can be flawed, making it harder to maintain industry standards.

Upholding higher quality standards in job shops and metal fabrication is crucial for long-term company reputation, regulatory compliance, and increased customer satisfaction. Without an ERP system, teams manually perform quality checks and maintain records on paper or scattered spreadsheets. This manual approach is prone to human error, omissions, and inconsistent documentation.

For example, inspection may miss minor defects, record measurements incorrectly, or fail to update records promptly. Over time, this can lead to undetected quality issues, rework, or even delivery of defective parts to customers. In industries where traceability is essential, such as aerospace, automotive, or medical components, flawed records make it difficult to prove compliance with standards or trace defects back to their source.

Manual quality management also slows down processes. Workers spend extra time cross-checking data, reconciling records, or verifying measurements, which reduces shop floor efficiency. Inconsistent or incomplete documentation increases the risk of customer disputes, returns, and damage to the shop’s reputation.

Making adjustments to designs in an ongoing manufacturing process manually is impossible, increasing scrap and costs.

In metal fabrication and job shops, changes to a design can arise at any stage, whether due to customer requests, engineering updates, or unforeseen material or machine constraints. Without laser cutting software solutions, manufacturers find it extremely difficult to adjust ongoing processes, since they depend on manual communication, printed drawings, or disconnected standalone software.

This lack of flexibility often leads to errors, rework, and material waste. For example, if a customer requests a last-minute modification to a part’s dimensions, the production team may struggle to implement the change quickly. Machines may continue to cut or bend metals according to the original design in manual updates, creating scrap parts. Reworking these parts requires more labor, materials, and machine time, which increases costs.

Manual adjustments increase the risk of miscommunication. Operators may misinterpret updated instructions, use outdated files, or fail to document changes properly, which can compound errors across multiple jobs. Over time, this inefficiency reduces throughput, increases operational costs, and impacts delivery timelines, ultimately affecting customer satisfaction and profitability.

Bottom-line

Operating a metal fabrication or job shop without an ERP system exposes businesses to inefficiencies at every stage, from quoting and material management to production scheduling, quality control, and delivery. Implementing metal fabrication ERP software addresses these challenges by centralizing operations, automating key processes, and providing real-time insights across quoting, production, inventory, and logistics.

Master Software Solutions offers ERP implementation services to manufacturing industries, including metal fabrication and job shops, automotive parts & accessories, electronics, and chemicals & fertilizers. We work on ERP platforms such as Odoo and Microsoft Dynamics 365 to build custom ERP solutions to cater to their specific requirements.