ERP stands for Enterprise Resource Planning. ERP systems are comprehensive solutions for managing an organization’s finances, operations, and data. The operations include the processes of various departments, including sales, inventory management, production, accounting, and quality control.

This blog examines the ERP system for bottled water manufacturing and how it enables businesses to streamline their end-to-end processes.

This blog covers:

Understanding the bottled water supply chain

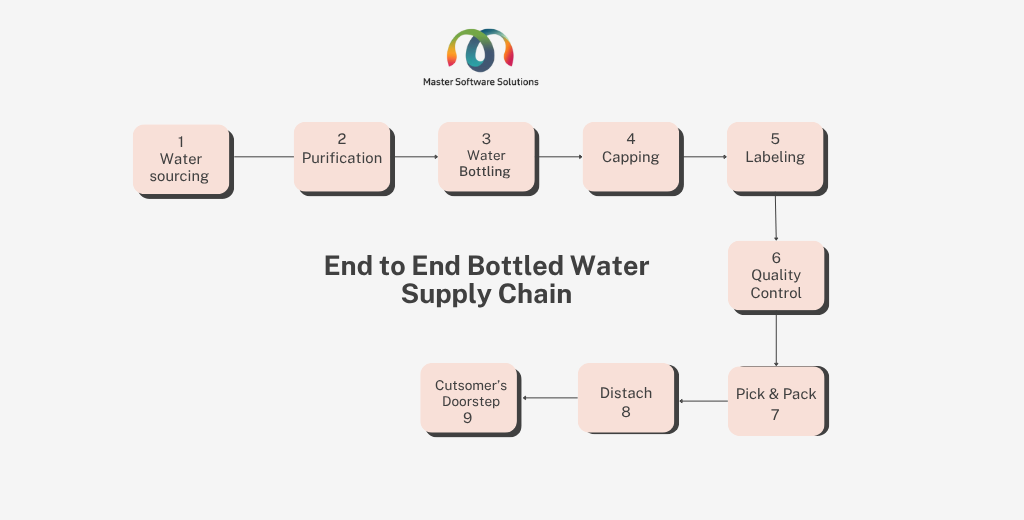

The global bottled water market size was estimated at USD 348.64 billion in 2024 and is projected to reach USD 509.18 billion by 2030, growing at a CAGR of 6.4% from 2025 to 2030. The bottled water supply chain includes a series of interconnected steps that ensure clean, safe, and reliable water is supplied to the consumers. Steps included in the bottled water supply chain are:

- Water sourcing – The water is sourced from natural springs, wells, or municipal supplies.

- Purification – After the water is collected, it is filtered and purified through processes, including reverse osmosis, UV treatment, or ozonation, to meet the water health standards.

- Bottling – The water is filled into plastic bottles or glass containers, sealed, and labeled.

- Distribution – The water bottles are distributed through wholesalers, retailers, or directly to consumers via vending or delivery services.

Logistics play a crucial role in maintaining the water quality and shelf life, especially with storage and transportation conditions. The water bottle end-of-life phase includes recycling, disposing of, or returning plastic bottles, highlighting the importance of sustainability within the bottled water supply chain.

Understanding the bottled water supply chain helps businesses optimize efficiency and helps consumers make informed choices about environmental impacts and water safety.

What is bottled water ERP?

A bottled water ERP is an enterprise resource planning system specifically configured and customized for bottled water businesses. The system consolidates multiple processes into a single platform, such as production management, inventory leveling, sales and distribution, CRM, finance and accounting, compliance and traceability, and mobile app integration.

This ERP aims to improve operational efficiency, provide better demand forecasting and inventory control, enhance customer satisfaction, and reduce errors and manual work while reducing overheads.

This comprehensive system empowers businesses to manage their end-to-end operations in a more integrated, transparent, and scalable way.

Challenges without ERP for bottled water businesses

The ERP connects data, systems, and its users, simplifying processes and boosting collaboration. Managing and gaining complete visibility into processes is difficult without a technological solution. Manual business management is inefficient and can lead to inaccurate data and delayed processes. Challenges faced by bottled water businesses without an ERP are:

Manual water quality checks are prone to human errors, which can lead to safety risks, costly recalls, and brand damage.

Ensuring water quality is crucial for safety and compliance. However, when this process is done manually, it increases the risk of human errors during testing, recording, and reporting. Mistakes, including incorrect pH readings, missed contaminants, or faulty data entry, can easily go unnoticed without an integrated ERP system.

These errors can allow contaminated or substandard batches to reach customers, posing serious health and safety risks. If unsafe products are detected later, the business must initiate costly recalls, which not only disrupt operations but also strain customer relationships. Over time, repeated issues can erode a brand’s reputation, causing customers to lose trust and switch to competitors. Such brand damage is hard to recover from.

Lack of real-time supply chain visibility delays responses, halts production and deliveries, and frustrates customers.

Bottled water businesses often struggle with disconnected systems that fail to provide real-time visibility into the supply chain. When disruptions occur, such as supplier delays, vehicle breakdowns, or route issues, managers can not detect them quickly. This impacts:

- Impact on production – Delays in raw material supply or missed replenishment updates stall production schedules, resulting in increased downtime.

- Impact on deliveries – Delivery teams work with outdated information, resulting in late or missed shipments.

- Impact on customers – Customers experience delays, unmet expectations, and service inconsistencies that frustrate them and harm brand reliability.

This lack of visibility not only increases operational costs but also weakens customer trust and loyalty over time.

Inaccurate demand forecasting lowers production efficiency, wastes raw materials, and reduces profit margins.

The demand in the bottled water businesses fluctuates based on seasonality, customer orders, and bulk requirements. Without an ERP system, forecasting is often manual or with disconnected tools, making it inaccurate and unreliable. This leads to

Production inefficiencies: When demand is underestimated, production falls short, resulting in stockouts and lost sales opportunities. Overestimation, on the other hand, results in overproduction.

- Waste of raw materials – Excess production leads to a buildup of unused bottles, caps, and water stock, increasing storage costs and waste.

- Reduced profit margins – Inefficient production planning and resource wastage increase operational costs, cutting into profit margins.

Bottled water businesses struggle to balance supply and demand, making it difficult to operate profitably in a competitive market.

Manual compliance processes increase errors, risk non-compliance, and erode customer trust.

In the bottled water industry, compliance with health, safety, and quality standards is critical. When these processes are managed manually, through spreadsheets, paper records, or disconnected systems, they become highly prone to errors. Even small mistakes in documentation or missed updates can have serious consequences. This results in:

- Increased errors – Manual data entry and record keeping often result in missing, duplicate, or inaccurate information.

- Non-compliance risks – Regulatory bodies require strict adherence to water safety, quality checks, and traceability. Errors or incomplete records can lead to violations, penalties, or even forced shutdowns.

- Loss of customer trust – Consumers expect bottled water brands to guarantee safety and transparency. Any compliance failure or reported violation damages brand reputation and drives customers towards the competition.

Compliance becomes harder to manage, more costly, and riskier without ERP. Businesses not only face legal and financial consequences but also risk losing customer confidence, a loss that is often difficult to rebuild in a competitive market.

Slow, non-automated customer service responses reduce satisfaction and retention.

Customers expect quick responses, whether it is about placing bulk orders, tracking deliveries, or resolving billing issues. Without a bottled water ERP or automated customer service tools, queries are handled manually through phone calls, emails, or paper records.

- Impact on operations – Manual handling increases response time, creates room for miscommunication, and makes it difficult to manage a large volume of requests efficiently.

- Impact on customers – Customers are facing delays in issue resolution or order confirmation, leading to frustration.

- Impact on business – Over time, slow service hurts customer satisfaction and loyalty, increasing the risk of losing repeat clients who offer faster, automated support.

Manual invoicing is difficult to track and prone to errors, resulting in customer disputes & dissatisfaction.

Relying on manual invoicing creates significant operational hurdles. Each invoice is created, recorded, and tracked separately, often using spreadsheet or paper-based systems. This process is not only time-consuming but also highly prone to human errors, such as incorrect billing amounts, missed entries, or duplicated records. These errors can lead to mismatched records, revenue leakages, and delayed payments. Customers may receive incorrect bills, which result in disputes, dissatisfaction, and damage to trust. Over time, this can hurt customer retention and increase administrative overhead for the business.

Overstocking or under stocking due to inaccurate inventory tracking, delaying deliveries, or missing selling opportunities

Bottled water businesses often rely on disconnected systems or manual methods to manage inventory. The lack of real-time visibility makes it difficult to maintain accurate stock levels across warehouses and distribution points. This leads to:

- Overstocking – Excess stock increases storage costs, risks product expiration, and ties up working capital.

- Under stocking – insufficient stock leads to missed sales opportunities, delayed deliveries, and dissatisfied customers

Both situations reduce profitability, hamper customer trust, and weaken the business’s ability to compete in bottled water market.

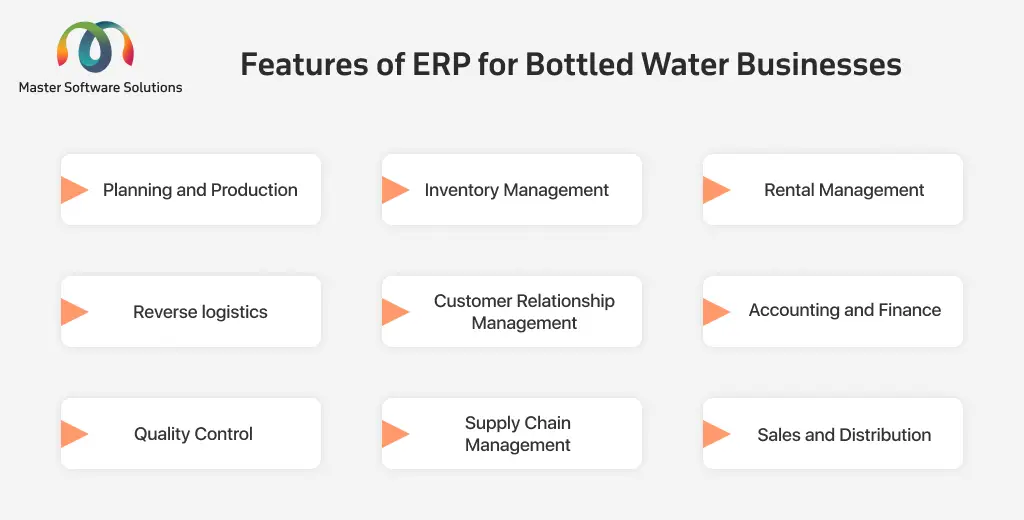

Features of ERP for bottled water businesses

The ERP for bottled water businesses provides features and functionalities to the bottled water industry. The system automates various business processes to streamline and optimize them, improving operational efficiency, productivity, and profitability while reducing overheads. The features of ERP for bottled water businesses are:

Planning and production to schedule production, allocate resources, batch & lot management, and integrated QC.

An ERP system aligns demand forecasts with manufacturing capacity for the bottled water company, streamlining production planning (the number of water bottles to be produced). You can schedule bottling operations based on customer orders and enable monitoring of key stages, including real-time water purification, bottle filling, capping, and labeling. This ensures optimal use of resources and minimizes production delays, increasing operational efficiency.

Inventory management for real-time stock visibility, auto-replenishment, batch/lot tracking, demand-based stock allocation, and IoT integrations

Effective inventory management is crucial for bottled water businesses. The system provides real-time visibility into stock levels of raw materials (caps, plastic bottles, and labels), packaging supplies, and finished goods. It alerts and automatically generates purchase orders when the stock level falls below the threshold, preventing overstocking or stockouts. The system supports batch tracking, ensuring traceability of each bottle batch for quality assurance and regulatory compliance.

Rental management for contract management, auto-invoicing, rental tracking, maintenance scheduling, & deposits/refund management

Many bottled water businesses rent out jars, dispensers, and water coolers. The ERP includes specialized rental management functionality for tracking assets by customer, scheduling recurring billing, and monitoring return status. It also records damages, losses, and maintenance needs. ERP’s rental module helps businesses reduce manual tracking, avoid revenue leakage, and maintain better control over their rented inventory.

Reverse logistics to manage & track empty bottles, refunds/credit notes, disposals, & inventory reconciliation, & optimize route for pickups.

The return of empty bottles and dispensers from customers is a critical aspect of bottled water businesses. The ERP for bottled water integrates return tracking into delivery workflows, offering reverse logistics. The delivery drivers can update the system with the quantity of empty jars collected, and the inventory levels are automatically updated. This ensures accountability, supports bottle reuse, and allows deposit/refund processes, streamlining time-consuming, manual, and error-prone processes.

CRM for a centralized database, subscription order processing, automated invoicing, customer segmentation, & complaint management

An ERP integrates a customer relationship management module. This helps manage customers, automate order handling, and personalize service. The system stores detailed customer profiles, order histories, preferences, and communication records. Businesses can easily manage subscription-based deliveries, recurring orders, and service requests for assets. The system also supports automated notifications such as order confirmations, delivery alerts, and payment reminders, ensuring increased customer satisfaction and retention.

Accounting and finance to manage GL, AP/AR, billing & invoicing, bank reconciliation, tax management, budgeting, & forecasting

The system consolidates all the financial data and automates the accounting functions. It handles invoice generation, payment tracking, expense management, tax calculation, and bank reconciliations. ERP systems generate real-time financial reports, including profit and loss statements, balance sheets, and cash flow analytics, providing accurate business financial insights. It ensures regulatory compliance with taxation laws and reduces the risk of errors associated with manual bookkeeping.

Quality control for automated water quality testing integrations, batch/lot traceability, audit trails, & compliance management

Maintaining water purity and adhering to safety standards is non-negotiable in this industry. The system enables you to embed quality checks at key production stages, enforcing quality control. You can define inspection criteria, record test results, and flag non-compliant batches for review. The system also supports equipment maintenance scheduling to prevent breakdowns, ensuring the production remains consistent with health and safety regulations.

Supply chain management to manage inventory, procurement, supplier/vendor, logistics, order, warehouse & return/reverse logistics.

An ERP system integrates procurement and logistics for a seamless supply chain workflow. It automates raw material procurement based on demand planning and current inventory levels. You can monitor vendor performance and track material delivery timelines, preventing production halts due to delays in raw material supply. The system provides visibility across the supply chain, enabling businesses to respond quickly to disruptions or changes in demand.

Sales and distribution to manage customers, subscription & recurring order processing, return & reverse logistics, & route & delivery planning.

The ERP system centralizes order management and distribution for B2B and B2C sales models. This enables businesses to manage sales orders, assign delivery routes, and track deliveries in real-time. It provides ideal features for direct-to-customer models, including mobile access for delivery drivers, digital payment reconciliation, and on-the-go order updates. The system ensures timely deliveries and smooth payment handling regardless of whether you are selling to offices, retailers, or households.

Benefits of an ERP system for bottled water businesses

The bottled water ERP provides numerous benefits for businesses, including increased operational efficiency, real-time insights, improved data security, and cost savings. It streamlines processes, automates workflows, and consolidates data to make informed decisions and boosts collaboration across departments. The benefits of implementing a bottled water ERP:

Accurate demand forecasting ensures that you have the correct stock available for order fulfillment, reducing waste & meeting customer needs.

An ERP software for bottled water manufacturers utilizes historical sales data, real-time order trends, and predictive analytics to generate reliable demand forecasts. This ensures:

Correct stock availability – The right amount of bottled water is always available for fulfillment.

- Reduced waste – Overproduction and expired stock are minimized.

- Customer satisfaction – Customer receive their orders on time, improving trust and loyalty

- Improved efficiency – Resources, including raw materials, labor, and machinery, are used optimally.

With ERP-driven forecasting, bottled water businesses can balance production and demand, reducing costs and enhancing service levels, which directly boosts profitability and competitiveness.

Optimized inventory management prevents stockouts and overstocking, ensuring timely deliveries and improving customer experience.

The ERP provides real-time visibility into inventory across warehouses, distribution centres, and delivery vehicles. Automated alerts signal when stock levels are low, while advanced analytics help forecast future demand based on sales trends and seasonal patterns. Optimized inventory management:

- Ensures timely deliveries to customers.

- Minimizes waste and excess storage costs.

- Improves customer satisfaction and loyalty by always having the right product available.

- Strengthens decision-making with data-driven insights into supply and demand.

Streamlined production planning & scheduling ensures optimal production, cutting downtime & timely manufacturing.

An ERP system for the bottled water industry synchronises production schedules with real-time demand, available resources, and delivery times. Instead of relying on manual planning or disconnected spreadsheets, ERP automates scheduling by taking into account machine capacity, workforce availability, and raw material stock. It enables:

- Optimizes production – Ensures the right quantity of bottled water is produced based on demand forecasts, reducing overproduction and shortages.

- Reduced downtime – Automated scheduling efficiently allocates machinery and labor, minimizing idle time and bottlenecks

- Timely manufacturing – Synchronizes production with delivery schedules to ensure that customer orders are fulfilled on time.

- Improved efficiency – Helps managers quickly adjust plans in case of supply chain disruptions or demand fluctuations.

With ERP, bottled water businesses can achieve greater efficiency, lower costs, and consistent on-time deliveries, strengthening customer trust and profitability.

Improving the sales & distribution process provides on-time deliveries, reduces last-mile costs, and improves customer satisfaction.

Sales and distribution are at the heart of daily operations. An ERP system automates order management, optimize delivery routes, and provides real-time visibility into inventory and logistics, streamlining the entire process. The system ensures:

- On-time deliveries – With automated scheduling and optimized routes, drivers can deliver orders faster and accurately.

- Reduced last-mile costs – Route optimization minimizes travel distance and fuel consumption, lowering distribution expenses.

- Better customer satisfaction – Timely deliveries, accurate order fulfillment, and transparent communication strengthen customer trust and loyalty.

Improving sales and distribution efficiency reduces operational costs but also ensures a consistently reliable customer experience.

Enhanced quality & compliance ensure high-quality products reach your customers, protecting brand reputation.

Product safety and compliance are critical in the bottled water industry. Without a centralized system, quality checks, and compliance documentation often rely on manual processes, which are prone to errors and inconsistencies. An ERP system integrates quality control at every stage of production, from water purification and bottling to packaging and distribution.

Automated alerts flag deviations, while batch and lot tracking ensure full traceability in case of issues. The compliance module also simplifies recordkeeping, making audits faster and more reliable. This ensures

- Consistent delivery of safe, high-quality bottled water to consumers.

- Reduced risk of contamination, recalls, and penalties.

- Builds and protects long-term brand trust and reputation.

Automating finance and accounting gives better control & transparency, strengthening cash flow and reporting.

Financial transactions flow in from multiple sources, including direct sales, subscription orders, wholesale clients, bottle returns, and logistics expenses. A bottled water ERP automates finance and accounting processes by centralizing accounting payables (AP), accounts receivable (AR), and general ledgers (GL) into one unified system. This ensures every transaction, from customer payments to supplier invoices, is recorded accurately and in real-time.

- Improves transparency – Provides a clear picture of revenues, costs, and outstanding payments at any given time.

- Strengthens cash flow – Timely invoice tracking and automated payment reminders reduce delays in receivables.

- Ensures accuracy – Minimizes human errors in financial entries and reconciliations.

- Supports compliance – Maintains accurate records for audits and regulatory requirements.

- Enables better decisions – Real-time financial reports and dashboards empower managers to make informed strategic choices.

Providing personalized customer service fosters stronger relationships, which increases customer retention and loyalty.

An ERP system consolidates customer data across sales, distribution, and service channels, providing a comprehensive view of customers for bottled water businesses. From purchase history and preferred delivery schedules to payment methods and service requests, all information is stored in one place.

The sales teams and drivers can access this data in real-time, enabling them to offer personalized solutions such as tailored delivery schedules, special pricing, or quick issue resolution. This makes your customers feel valued and well served, which builds trust and satisfaction. Over time, this personalized approach fosters stronger relationships, increasing customer retention and loyalty, and encouraging repeat business in a competitive market.

How does Master Software Solutions help you implement a bottled water ERP?

Master Software Solutions is an IT service provider for businesses seeking digital transformation services. We provide one-stop ERP consulting services, including customizations, integrations, development, and migrations. Our ERP services extend to ongoing support and maintenance. We work on multiple platforms, including Odoo, Microsoft Dynamics Business Central, and TrakOp.

Odoo

We offer comprehensive Odoo consulting services for small and medium enterprises. Odoo is an open-source platform that provides integrated multiple business applications, enabling you to manage and track all your bottled water operations from one screen. Our Odoo services include implementation, migration, customization, consulting, integration, website development, module development, and support & maintenance.

Microsoft Dynamics 365

We offer consolidated Microsoft Dynamics 365 consulting services for larger enterprises. Our Microsoft Dynamics 365 consulting services include customization & integration, business process consulting, CRM modernization, development and engineering, and Dynamics managed services.

TrakOp

TrakOp is a subscription-based, scheduled management delivery software that automates the ordering process, delivery planning, and route optimization. This is our in-house product designed for businesses like bottled water businesses for whom subscription management is crucial. It provides three platforms, including the admin panel and a mobile app for customers and delivery drivers.