The dairy industry operates in a complex and fast-paced environment, where freshness, traceability, and quality control are non-negotiable. From milk collection and production to inventory management, distribution, and compliance, dairy businesses handle interconnected operations daily. As the industry evolves, traditional or manual methods are insufficient to meet ever-changing customer expectations and regulatory demands. This is where an advanced ERP for the dairy industry becomes essential.

With so many options available, how do you choose the best dairy ERP tailored to your dairy operations? This blog discusses key factors to consider, must-have modules, and how the right ERP can help increase efficiency, ensure compliance, and improve profit margins across your dairy supply chain.

This blog covers:

What is ERP for the dairy industry?

ERP for the dairy industry is a specialized enterprise resource planning system designed to manage and integrate all core dairy business operations. It helps streamline and automate processes, including milk collection, production, quality control, inventory, sales, distribution, compliance, and financial management, all within a unified platform. Key functions of dairy ERP:

- Milk collection management – Track milk quantity, quality (fat/SNF), and supplier payments.

- Production planning – Manage the raw milk process into products such as curd, ghee, and cheese.

- Inventory control – Monitor stock levels, shelf life, and cold storage logistics.

- Quality assurance – Automate testing and ensure compliance (FSSAI, BIS, ISO)

- Sales and distribution – Route planning, order tracking, and delivery management.

- Finance and accounting – Real-time financial reporting, costing, and profit tracking.

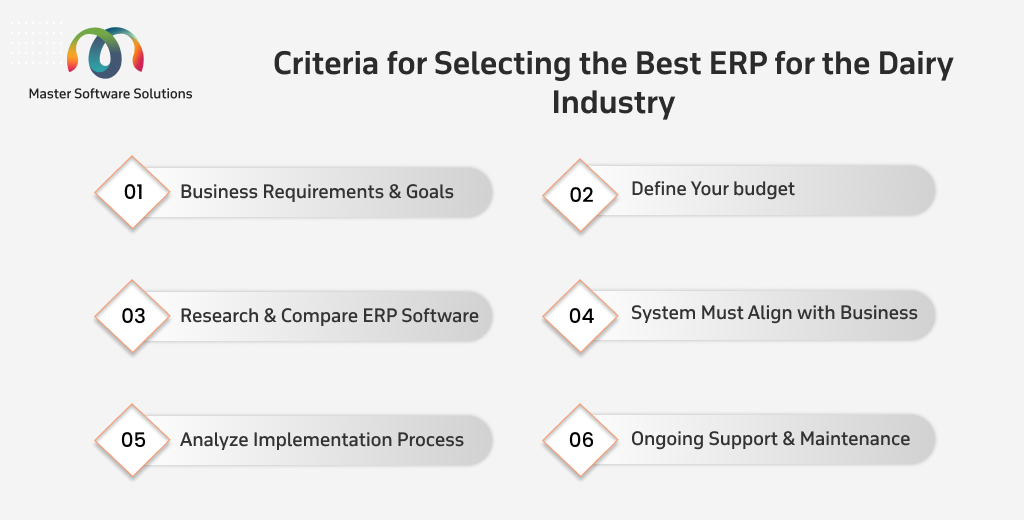

Criteria for selecting the best ERP for the dairy industry

It is vital for any dairy business aiming to improve efficiency, ensure compliance, and remain competitive to pick the right ERP system. Here are the factors you should consider while picking the best ERP for the dairy industry:

Identify your business requirements and goals

You can start by mapping out your dairy operations, from milk collection and production to quality checks, inventory, and distribution. Define what problems you want to solve with ERP and the outcomes you expect.

Define your budget

Now, determine how much you are willing to invest, not just in a software license, but in implementation, training, customization, and ongoing support to ensure that your system operates efficiently. A clear budget helps narrow down suitable ERP solutions.

Research and compare various dairy ERP software

Explore various dairy ERP software tailored for dairy businesses. Compare their features, industry-specific modules, scalability, integrations, and customer reviews to assess their fit for your needs.

Ensure the system aligns with your business

The ERP system you choose should support your current operations while also being adaptable enough to grow with your business. Make sure it integrates smoothly with your existing tools (accounting, logistics, or CRM system).

Analyze the implementation process of your ERP partner

Look for ERP vendors that offer a structured, transparent implementation roadmap. Consider timelines, training, data migration, and how the vendor handles your onboarding to reduce downtime.

Look for ongoing support and maintenance

Post-implementation support is crucial. Ensure the ERP provider offers regular updates, technical assistance, and scalability options. Your system should stay current and reliable as your business evolves.

Must-have dairy ERP modules

Managing a dairy business involves more than just processing and distributing milk; it also includes ensuring quality, maintaining traceability, optimising resources, and staying compliant with strict regulations. Managing these unconnected operations efficiently needs a robust ERP system with industry-specific functionalities. These must-have dairy ERP software modules are:

Milk collection management

It enables you to manage raw milk procurement from multiple sources such as farmers, cooperatives, or collection centres. This module ensures accurate payments to the suppliers, complete traceability, and transparency in procurement. Features of the milk collection management module:

- Fat and SNF testing and recording

- Rate chart automation based on quality parameters

- Supplier (farmer) account management

- Real-time data entry from milk collection centres

Production and processing module

The system handles all aspects of converting raw milk into finished dairy products, including curd, butter, ghee, and cheese. This enhances production efficiency, minimizes wastage, and ensures consistent product quality. The features of the production and processing module are

- Production planning and batch management

- Recipe/formulation processing

- Yield tracking and loss analysis

- Resource and capacity planning

Quality control module

This enables monitoring quality at every stage, from raw milk to finished goods, enhancing brand trust, ensuring regulatory compliance, and reducing product recalls. The features of the quality control module are

- Automated quality testing (SNF, fat, and bacterial count)

- Compliance with FSSAI and other food safety standards

- Quality alerts and rejection logs

Inventory management module

Track and manage stock levels of raw milk, material, packaging, and finished goods, reducing spoilage, ensuring timely dispatch, and maintaining optimal stock levels. The key features of the inventory management module are:

- Real-time inventory visibility

- Expiry date and shelf life tracking

- Cold storage and multi-location warehouse management

- FIFO/FEFO tracking

Sales and order management module

This module streamlines order processing from distributors, retailers, and direct customers, enhancing customer satisfaction through timely deliveries and efficient billing. The key features of the sales and order management module are

- Order entry and tracking

- Route planning for delivery

- Discount and pricing management

- Invoicing and e-way bill generation

Distribution & logistics module

This module enables you to manage logistics, cold chain transport, and delivery operations. The key features of the distribution and logistics module are:

- Route optimization

- Vehicle tracking and fleet management

- Delivery proof and return management

Finance and accounting module

The finance and accounting module of dairy ERP helps you maintain accurate financial records and support cost control. This enhances financial transparency and supports better budgeting and forecasting. The features of the finance and accounting module are

- General ledger, payables, receivables

- Costing and profitability analysis by product or department

- GST compliance and tax reporting

- Bank reconciliation and financial statements

Customer relationship management module

The CRM module helps you manage customer relationships and after-sales service. This enhances customer retention rates and service experience. The key features of the customer relationship management module are

- Customer data and communication history

- Complaint tracking and resolution workflows

- Loyalty programs for B2B and B2C clients

Business intelligence and reporting module

This module consolidates all your business data from various modules to provide actionable insights across departments. This enables data-driven decision-making and strategic planning. The features of the business intelligence and reporting module are:

- Custom dashboard for production, finance, and sales.

- KPI tracking (milk yield, production costs, and delivery efficiency)

- Real-time alerts and trend analysis

Compliance and traceability module

This module ensures traceability of each batch and meets food safety regulations, minimizing risk, enhancing food safety, and building customer trust. The features of the compliance and traceability module are

- Batch and lot tracking

- Audit trail for all transactions

- Automated documentation for regulatory bodies

How can the right ERP help your dairy business?

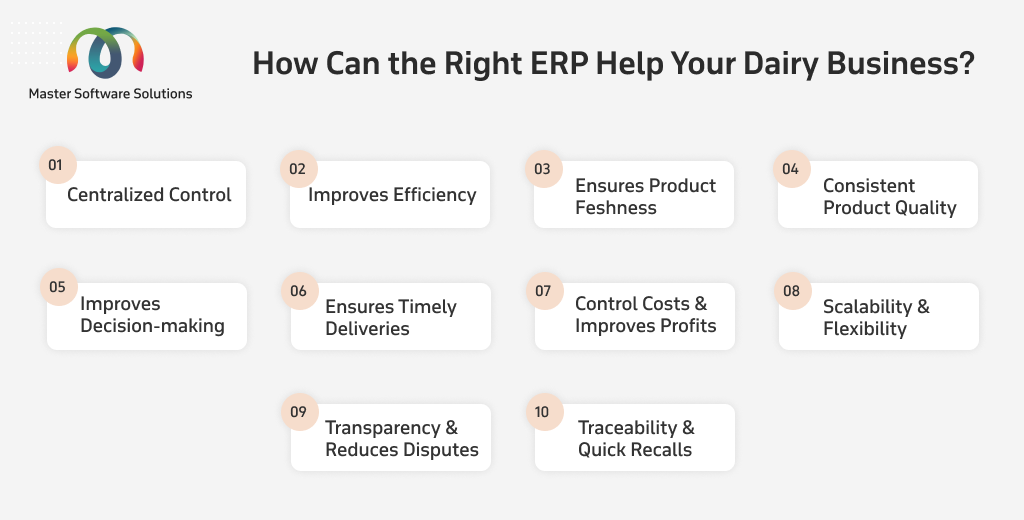

Implementing the right ERP for the dairy industry can help you transform your operations by streamlining operations, improving traceability, and enabling data-driven decisions. Here are the ways a right dairy ERP can help your business:

Centralized control for smooth coordination across departments, improving order accuracy and customer satisfaction

ERP software for the dairy industry integrates all processes, from milk collection and production to sales and delivery, into one unified platform. This eliminates data silos, ensuring smooth coordination between departments.

Automation improves efficiency and reduces manual work, increasing

Automation of tasks like procurement, inventory updates, billing, and compliance reporting saves time, reduces errors, and frees up staff for higher-value activities.

Real-time inventory tracking ensures product freshness, improving customer experience

Tracking your perishable stock in real-time using FIFO/FEFO logic reduces spoilage and optimizes cold storage capacity, ensuring freshness and minimizing losses.

Automated quality control ensures consistent product quality, enhancing compliance

The ERP system captures quality checks data at every stage, from raw milk testing (fat/SNF) to final product release, helping your business meet global and national food safety standards with full audit trails.

Real-time insights from dashboards improve decision-making, reducing disruptions and costs

The dashboards and reports provide real-time visibility into production yield, delivery efficiency, sales trends, and costs, helping you respond quickly to changing demand or supply issues.

Optimized distribution ensures timely deliveries, improving customer satisfaction

Plan delivery routes, track vehicles, and manage last-mile deliveries efficiently. The dairy ERP software minimizes fuel costs, improves on-time delivery rates, and boosts customer satisfaction.

Cost tracking identifies inefficiencies to control costs, improving profits

Track costs across every process (milk procurement, processing, logistics, etc.) to identify efficiencies and improve profit margins through smarter resource allocation.

Modular structure and flexibility ensure system adaptability, supporting scaling

Modern dairy ERP solutions have a modular architecture and are adaptable, allowing them to grow with your business as you add new products, processing units, or expand distribution.

Automated supplier payments improve transparency, reducing disputes

The system automates farmer/supplier billing based on milk quality and quantity, enhancing trust and reducing payment disputes, which is crucial for long-term supplier relationships.

Batch-tracking improves product traceability, ensuring quick recalls and enhancing brand image

ERP systems enable batch-wise tracking from farm to shelf, allowing for fast response in case of quality issues or recalls, protecting your brand and consumers.

Conclusion

Choosing dairy ERP software for manufacturers is a long-term investment and decision. It is essential to weigh all options before committing to one. Additionally, consider taking a demo or asking to showcase their similar projects that they have worked on.

Master Software Solutions is an IT-based service provider with more than 10 years of experience catering to dairy businesses. We offer end-to-end ERP services, including ERP consulting, implementation, migration, configuration, development, and ongoing support and maintenance. Our ERP experts work on Odoo and Microsoft Dynamics 365 to provide one-stop tailored solutions for various industries, including dairy.