In the metal fabrication industry, precision, speed, and efficiency are paramount to success. Laser cutting operations require accurate demand planning, real-time visibility, and seamless coordination across departments, from quoting and scheduling to inventory and delivery. Manual or conventional approaches to managing these processes frequently fail to keep up. This is where laser cutting ERP software comes in.

What is a laser cutting ERP? – A laser cutting ERP (Enterprise Resource Planning) is a specialized software solution designed to manage and automate every aspect of a laser cutting or metal fabrication business. It integrates various business functions, including production planning, inventory management, scheduling, quality control, and accounting, into one centralized system.

This blog covers the benefits of implementing laser cutting ERP in your metal fabrication and job shops.

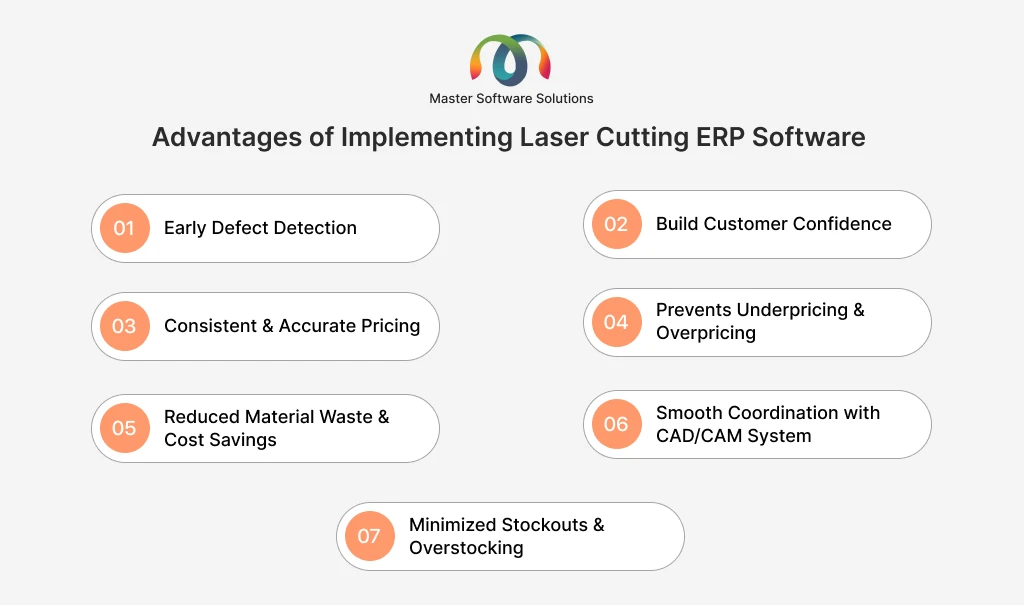

Advantages of implementing laser cutting ERP software

An ERP for metal fabrication and job shops integrates production, inventory, quality control, and financial data into a unified platform. This helps businesses to reduce waste, optimize resource utilization, and ensure on-time project completion. The advantages of laser cutting ERP software for metal fabrication and job shops:

Early defect detection

Implementing laser cutting ERP software enables real-time monitoring of production processes, machine performance, and material quality across all stages of fabrication. The system integrates automated quality control checkpoints and inspection data directly into the workflow, allowing operators to detect issues such as incorrect dimensions, poor edge quality, or material inconsistencies early in the production cycle.

Identifying and addressing defects before they escalate enables businesses to reduce waste, minimize rework, and ensure consistent output quality. Automated alerts and analytics dashboards provide immediate visibility into performance deviations, helping teams take corrective action quickly.

The key KPIs that are improved include:

- Scrap Rate Reduction: Measures the percentage of raw material wasted during production due to defects or errors.

- Rework Time: Tracks the total time spent correcting or remanufacturing defective parts.

- First Pass Yield (FPY): Indicates the percentage of products that meet quality standards without rework.

- Production Downtime: Measures the amount of time production is halted due to quality-related issues or inspections.

- Customer Complaint Rate: Represents the number of customer-reported issues or returns resulting from product defects.

Build customer confidence

Laser cutting ERP software helps metal fabrication and job shop businesses deliver consistent quality, accurate timelines, and transparent communication. Integrating every step of the process from quoting and order tracking to quality inspection and delivery ensures customers receive real-time updates and reliable service.

With precise job tracking and quality documentation, clients can verify that their parts meet specifications and standards. This improves transparency, reduces delivery issues, and builds stronger long-term relationships based on reliability and accountability.

Key KPIs improved are:

- On-time delivery rate: Measures the percentage of orders completed and delivered within the agreed timeline.

- Customer Satisfaction Scores (CSAT): Evaluates customer satisfaction with the overall service and product quality.

- Customer Retention Rate: Indicates the percentage of customers who continue to place repeat orders or renew contracts over time.

- Order Accuracy Rate: Tracks how often customer orders are fulfilled correctly without errors or missing components.

- Net Promoter Score (NPS): Gauges how likely customers are to recommend your services to others based on their experience.

Consistent & accurate pricing

Fluctuating material costs and changing tariffs can significantly impact profitability for metal fabrication businesses. A laser cutting ERP software with dynamic pricing capabilities automatically updates product and service prices on current tariffs, raw materials, and other market factors. This automation ensures that every quote, order, and invoice reflects the most accurate and consistent pricing.

Eliminating manual price updates helps businesses protect their profit margins, reduce administrative errors, and resolve customer disputes caused by inconsistent or outdated pricing. The system maintains clear cost breakdowns and audit trails, providing transparency to the clients.

KPIs improved are:

- Gross Profit Margin: Measures the profitability of each job after accounting for direct costs such as materials and labor.

- Quote-to-order Conversion Rate: Tracks the percentage of customer quotes that successfully convert into confirmed sales orders.

- Pricing Error Rate: Indicates the frequency of pricing inaccuracies across quotes, invoices, or purchase orders.

- Customer Dispute Rates: Measures the frequency with which customers express concerns or conflicts about pricing or billing discrepancies.

- Administrative efficiency: Assesses the effectiveness of pricing and billing processes that are managed with minimal manual intervention.

Prevents underpricing and overpricing

Preparing accurate quotes in the metal fabrication industry is critical, as it requires careful consideration of numerous factors, including material type and thickness, cutting time, labor, machine usage, overheads, and waste. Manual quoting often leads to underpricing, which reduces profit margins, or overpricing, which results in lost business opportunities.

A laser cutting ERP system automates cost calculations by pulling real-time data from CAD/CAM files, material inventories, and labor rate configurations. This ensures that every quote is based on actual production parameters and up-to-date costs. The result is faster quote generation, consistent pricing, improved profitability, and enhanced customer credibility.

Key KPIs improved include:

- Quote Accuracy Rate: Measures the closeness in estimated quotes with actual production costs.

- Quote Turnaround Time: Tracks the time taken to prepare and deliver a customer quote.

- Gross Profit Margin: Indicates the profitability of each job after accounting for direct costs.

- Quote-to-order Conversion Rate: Reflects the percentage of quotes that successfully turn into confirmed orders.

- Customer Trust Index: Gauges the level of customer confidence in your pricing accuracy and reliability.

Reduced material waste & cost savings

Laser cutting ERP software integrates with nesting optimization tools, enabling metal fabrication businesses to maximize sheet utilization and minimize material waste. The system intelligently arranges parts on metal sheets to ensure the best possible fit, while remnant tracking identifies and reuses leftover materials for future jobs.

This seamless integration helps reduce unnecessary material purchases, lower production costs, and improve overall profitability. Cutting waste and improving material efficiency enable businesses to save costs and operate sustainably, supporting both financial and environmental goals.

Key KPIs improved are:

- Material Utilization Rate: Measures how efficiently raw materials are used during the cutting process.

- Scrap Rate: Indicates the percentage of material lost or wasted during production.

- Raw Material Cost per Job: Tracks the total cost of materials consumed for each order or batch.

- Inventory Turnover Ratio: Evaluates how quickly materials are used and replenished within a specific period.

- Gross Profit Margin: Reflects overall profitability after accounting for material and production costs.

Smooth coordination with the CAD/CAM system

The ERP system seamlessly integrates with CAD/CAM systems to create a unified and automated production workflow. This integration allows businesses to import design data directly into their ERP system, including part geometry, material type, and cutting paths. These details are automatically transferred to nesting, scheduling, and machine programming modules.

This eliminates the need for manual data entry, minimizing the risk of human error and ensuring precise execution on the shop floor. This improved coordination between design and production teams, faster job setup, and more efficient production cycles.

Key KPIs that are improved include:

- Data Accuracy Rate: Measures the consistency and correctness of design and production data shared across systems.

- Production Lead Time: Tracks the total time from design approval to job completion.

- Error Rate: Indicates the frequency of production errors caused by incorrect or duplicated data entries.

- Engineering Change Cycle Time: Measures the time required to implement design changes into production.

- Operational Efficiency: Assesses how effectively different departments, including design, production, and quality, collaborate through system integration.

Minimized stockouts & overstocking

ERP software provides real-time visibility into inventory levels, purchase orders, and material usage across all production stages. When stock levels reach predefined thresholds, the system automatically generates purchase orders (POs) to replenish materials, ensuring uninterrupted production.

The system enables you to link inventory directly to job requirements, ensuring that the right materials are always available when needed. This automation reduces downtime caused by material shortages, prevents overstocking, and improves cash flow. This automation reduces downtime caused by material shortages, prevents overstocking, and improves cash flow by optimizing purchasing cycles and storage costs.

Key KPIs improved are:

- Inventory Turnover Ratio: Measures how efficiently materials are used and replaced within a given period.

- Stockout Rate: Frequency of production delays because of unavailable materials.

- Procurement Cycle Time: Tracks time between initiating a purchase order and receiving materials.

- Carrying Cost of Inventory: Represents the total cost of holding inventory, including storage and depreciation.

- Order Fulfillment Rate: Measures the percentage of production orders completed on time due to adequate material availability.

Bottom-line

Implementing a laser cutting ERP system gives you an advantage in today’s competitive landscape through efficiency, precision, and cost control. Its unified platform connects design, production, inventory, quality, and customer management, transforming the entire metal fabrication and job shop businesses.

Master Software Solutions offers end-to-end ERP consulting services, including implementation, migration, customization, and development. We collaborate with Odoo and Microsoft Dynamics (ERP platforms) to meet specific business needs. If you are looking for ERP implementation, contact us to discuss your business!