Freshness, quality, and time-to-market are crucial for the beverage industry. This industry faces constant pressure to streamline operations while meeting ever-evolving consumer demands and regulatory standards. Managing inventory, production, compliance, and distribution across multiple channels can take time if you don’t have the right system. This is where the beverage ERP system comes in, which is designed to optimize complex business operations.

Implementing a beverage ERP system provides real-time visibility, process automation, and data-driven decision-making. This blog explains the benefits of a beverage ERP system and how it can improve operational effectiveness, product consistency, and long-term growth.

What is a beverage ERP system? – A beverage ERP system is a comprehensive platform for businesses to streamline and optimize their entire operations. It provides a unified platform to manage beverage production, inventory, orders, quality checks, and distribution. The system aims to enhance operational efficiency, productivity, and profits while reducing overheads.

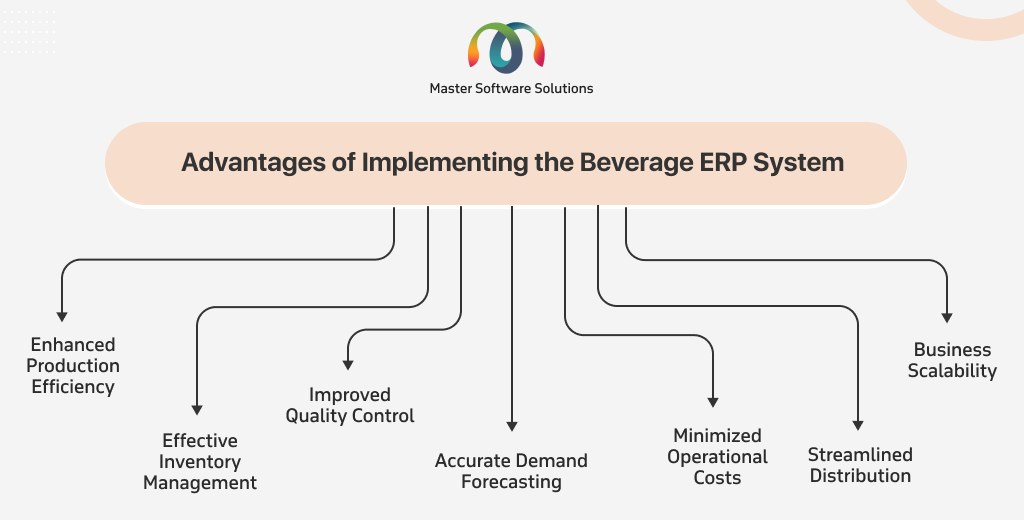

Benefits of implementing the beverage ERP system

The ERP for beverage industry offers various benefits that can help businesses boost their revenue and long-term growth. It centralized the database to improve consistency and accuracy, ensuring the right production and order fulfillment. The advantages of implementing the beverage ERP system are:

Enhanced production efficiency

This is one of the most significant benefits of implementing an ERP system in the beverage industry. ERP centralizes and automates production planning, scheduling, and execution, reducing manual intervention and minimizing errors. Integrating data from ERP modules such as sales forecasts, inventory levels, and supply chain activities helps optimize batch production, ensure the timely availability of raw materials, and minimize downtime.

Real-time visibility into the entire production process enables managers to identify bottlenecks, track performance metrics, and make informed decisions quickly. Additionally, ERP systems support healthy manufacturing practices, reduce waste and overproduction, lower costs, and faster turnaround times. This leads to a more agile and responsive production environment that consistently helps meet quality standards and delivery deadlines.

Effective inventory management

Inventory management is crucial in the beverage industry, where shelf life, batch tracking, and demand fluctuations play critical roles. An ERP system provides real-time visibility into stocks (raw materials, packaging supplies, or finished goods) across multiple locations, streamlining inventory control. It automates stock tracking, reordering points, and inventory movement within or outside of the warehouse. This reduces the chances of stockouts, overstocking, and product spoilage.

Businesses can implement just-in-time inventory strategies, monitor expiration dates, and manage batch and lot numbers. It improves coordination between procurement and production teams, ensuring materials are available exactly when needed. An ERP-driven inventory management reduces storage costs, minimizes waste, and guarantees product availability to meet market demands efficiently.

Improved quality control

Maintaining high product quality is non-negotiable in the beverage industry. Consistency, safety, and compliance are important factors in long-term business success. ERP integrates quality checks and protocols directly into the production workflow, enhancing quality control. This ensures that every stage is monitored and documented, from raw material inspection to in-process testing and final product evaluation.

Centralizing data management with the beverage ERP enables tracking real-time quality metrics, deviations, and non-conformances. It can trigger automatic alerts when quality standards are not met, allowing immediate corrective action. The system maintains detailed audit trails and facilitates traceability through batch and lot tracking, supporting compliance with industry regulations. This results in reducing the risk of recalls, improving product consistency, and building stronger trust through reliable and repeatable quality processes.

Accurate demand forecasting

Accurate demand forecasting is crucial for balancing production, inventory, and customer expectations, specifically in a fast-moving beverage industry. The ERP system consolidates historical sales data, seasonal trends, market insights, and current order patterns into a single, integrated platform, enhancing forecasting. AI-driven forecasting and advanced analytics can help identify patterns and predict future demand with greater precision than manual methods.

This insight enables businesses to plan production runs more effectively, reduce excess inventory, and avoid stockouts or last-minute procurement costs. It also aligns supply chain and distribution activities with real-time market needs. Accurate forecasts help businesses in responding to changing consumer behavior, promotional campaigns, and market shifts, ensuring smoother operations, higher customer satisfaction, and improved profitability.

Minimized operational costs

Implementing an ERP software for beverage manufacturers streamlines processes, eliminates redundancies, and improves resource utilization, reducing operational costs. In the beverage industry, the margins can be tight, and inefficiencies are costly. ERP systems help reduce waste through better production planning, optimize inventory management, and automate workflow.

Minimizing manual tasks and errors, ERP reduces labor costs and prevents costly mistakes in procurement, production, and order fulfillment. Real-time data and analytics enable businesses to make smarter decisions, allowing them to identify cost-saving opportunities such as supplier consolidation, better inventory turnover, and streamlined distribution strategies. The ERP system enforces standardized procedures and ensures timely audits and documentation, lowering compliance and quality-related expenses. The systems drive cost efficiency across the supply chain while maintaining high service and product standards.

Streamlined distribution

Efficient distribution is crucial in the beverage industry, where timely delivery and product freshness can directly impact customer satisfaction and brand reputation. The ERP system enhances distribution by providing real-time visibility into inventory levels, order status, delivery schedules, and logistics operations.

It can automate order processing, optimize delivery routes, and coordinate warehouse and transportation activities effectively, ensuring accurate order fulfillment, reducing delivery errors, and supporting multi-location distribution management. Outbound operations are streamlined by integrating the system with real-time tracking features and third-party logistics (3PL) providers.

This enables faster and more reliable deliveries, reducing transportation costs. It offers greater flexibility to meet customer demands for direct-to-store delivery, bulk shipments, or time-sensitive B2B orders. Improving the distribution process allows businesses to scale operations while maintaining consistency, efficiency, and service excellence.

Business scalability

Beverage businesses seeking to expand (new product lines, entering new markets, or increasing production capacity) need systems that can grow with them. An ERP system for beverage manufacturers is designed keeping scalability in mind, allowing companies to adapt and expand operations without disrupting existing workflows.

These platforms can accommodate increasing data volumes, complex supply chains, and multi-location operations. The system ensures smooth coordination and data consistency across all the business units. It allows you to handle onboarding new suppliers, launching in new regions, or integrating with e-commerce platforms and third-party distributors.

The modular ERP architecture allows businesses to add new features, such as mobile sales, advanced analytics, or customer portals, as per their preferences. This flexibility empowers beverage companies to pursue growth confidently. The system can scale alongside their ambitions, without the need for constant system overhauls or costly implementations.

Bottom-line

Implementing the right beverage ERP for your business is crucial to staying ahead in the competitive market. The system provides an integrated platform that ensures production efficiency, accurate inventory control, strengthens quality management, and enables precise demand forecasting. The system aims to reduce operational costs, improve distribution, and position your business for sustainable growth. Beverage ERP implementation is a strategic move that delivers long-term value.

Master Software Solutions is an IT service provider that offers end-to-end ERP software for beverage manufacturers. We also provide ERP consultation services for beverage industries, including bottled water, coffee, and dairy. Discuss your business goals and see how our ERP experts can help you achieve them. Schedule a Consultation.