Are manual records, disconnected systems, and delayed reports slowing down your dairy operation? From milk collection and quality testing to production planning and distribution, managing a dairy business involves many moving parts, each demanding accuracy, speed, and compliance.

Now consider this:

- What is milk procurement data from collecting centers updated in real-time?

- What if quality tests, inventory levels, and production yields were visible on a single dashboard?

- What if financial tracking, regulatory reporting, and farmer payments were all automatic without the need for spreadsheets or paperwork?

This is the reality for dairy businesses that have adopted ERP software specifically for the dairy industry.

As the competition increases and margins tighten, automation has become strategically crucial. This blog sees how ERP software is helping dairy businesses streamline operations, reduce losses, ensure traceability, and gain full control over their end-to-end processes, from farm to finished product.

Table of Contents

What does automation in the dairy business mean?

Automation in the dairy business refers to the systematic use of digital systems, software, and connected technologies to manage, control, and optimize dairy operations with minimal manual intervention. Instead of relying on paper records, spreadsheets, or disconnected tools, automation integrates core processes into a single, structured workflow.

In practical terms, dairy automation means:

- Capturing milk quantity and quality data digitally at collecting centers, automatically calculating prices, and generating farmer payments without manual calculations.

- Managing batch processing, recipes, yields, and equipment usage through predefined rules and real-time data tracking.

- Automatically tracking raw materials and work-in-progress (WIP) and maintaining traceability and audit-ready records across the supply chain.

- Linking procurement, production, sales, and accounting so that costs, revenues, and profitability are calculated in real time.

Challenges faced by dairy businesses without automation

Dairy businesses that operate without automation face a range of operational, financial, and compliance-related challenges. As volumes increase and regulations become stricter, manual and semi-digital processes often create inefficiencies that directly impact profitability and scalability. Below are the key challenges commonly faced by non-automated dairy operations:

Manual data entry and human errors

Manual record-keeping increases the risk of errors in milk quantity, quality, and pricing data. These errors can lead to reconciliation issues, reporting delays, and financial losses. Maintaining data accuracy becomes difficult as operations grow.

Lack of real-time visibility

Without automation, access to operational data is slow and fragmented, resulting in a lack of real-time insights into procurement, production, and inventory. This results in slower decisions and reduced operational control.

Inefficient milk procurement management

Manual procurement processes cause inconsistencies in milk collection and quality records. Payment delays and calculation errors can lead to dissatisfied farmers. Tracking supplier performance becomes difficult with centralized data.

Production inefficiencies and higher wastage

Limited production monitoring results in poor yield control and higher wastage. Process deviations often go unnoticed until losses happen. Reactive equipment maintenance increases downtime and costs.

Inventory and cold chain losses

Inaccurate stock tracking results in overstocking, shortages, and expired products. The lack of an expiry date and temperature monitoring increases the risk of spoilage. Inventory losses directly impact profitability.

Compliance and traceability risks

Manual compliance management increases the risk of documentation gaps and audit failures. Traceability during quality issues is slow and unreliable. Regulatory response becomes time-consuming and stressful.

Weak financial control and cost visibility

Delayed financial data limits cost tracking and profitability analysis. Manual accounting reduces reporting accuracy and timeliness. This weakens cash flow management and decision-making.

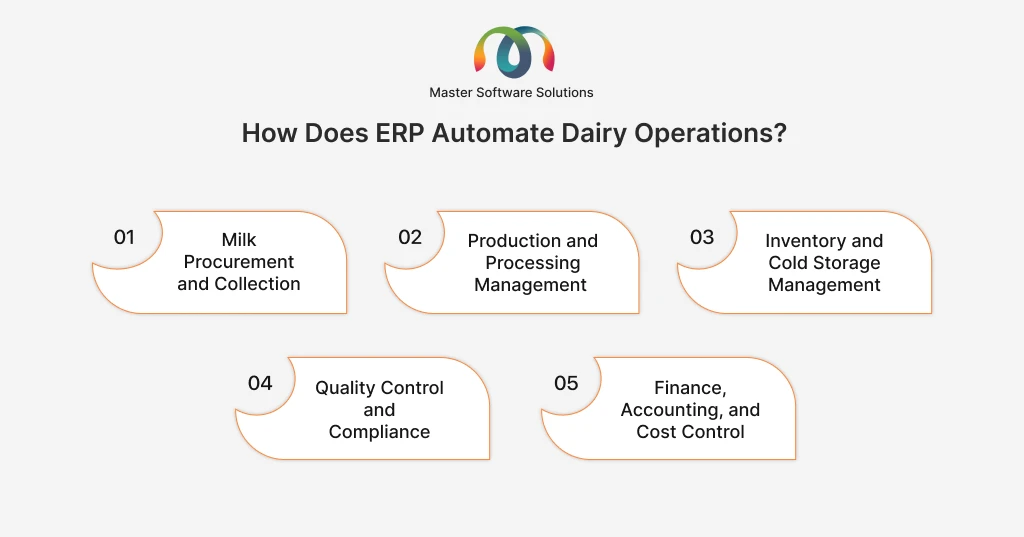

How does ERP automate dairy operations?

ERP software for the dairy industry automates operations by integrating procurement, production, inventory, quality, and finance into a single system. This ensures data flows seamlessly across departments, reducing manual efforts and improving control, accuracy, and decision-making. Ways ERP for dairy businesses automates operations.

Milk procurement and collection

ERP automates milk procurement by digitalizing farmer onboarding, contract terms, and pricing structures. Milk collection data, such as quantity, fat, and SNF values, is captured in real time, often integrated directly with weighing scales and testing equipment. This eliminates manual entries and inconsistencies across collection centers. Based on predefined pricing rules, the system automatically calculates milk value and generates farmer payments. The result is faster settlements, improved transparency, and stronger relationships with farmers.

Production and processing management

In dairy processing, ERP automates batch planning, recipe management, and production scheduling. Each production batch is tracked digitally, allowing accurate monitoring of yields to control wastage and improve efficiency. ERP also tracks equipment usage and schedules preventive maintenance to minimize downtime. This leads to consistent product quality and optimized plant performance.

Inventory and cold storage management

ERP provides real-time visibility into raw materials, work-in-progress (WIP), and finished goods across warehouses and cold storage units. Stock movements are recorded automatically, ensuring accurate inventory levels at all times. The system tracks expiry dates and shelf life to prevent spoilage and reduce write-offs. Demand-based planning tools help maintain optimal stock levels based on sales forecasts. This improves inventory turnover and reduces cold chain losses.

Quality control and compliance

Quality control processes are automated through predefined testing workflows and digital record-keeping. The ERP system ensures that quality checks are performed at each stage, from milk collection to final dispatch. Test results are stored centrally, making regulatory reporting and audits faster and more reliable. In the case of quality issues, the system enables full traceability from farm to consumer. This strengthens compliance, food safety, and brand trust.

Finance, accounting, and cost control

ERP streamlines financial processes by combining procurement, production, sales, and accounting data. Invoicing, payments, and ledger entries are generated automatically, with less manual intervention. The system enables accurate costing at the product, batch, or plan level, providing clear visibility into profitability. Real-time financial reports enable faster and more effective decision-making. This ensures tighter cost control and better economic governance.

Also Read: Odoo for Dairy Manufacturing: Revolutionizing the Dairy Industry

Benefits of automating the dairy business with dairy ERP software

ERP software helps dairy businesses streamline operations, improve accuracy, and gain better control over their end-to-end processes. By automating core functions and centralizing data, ERP enables efficient operations, informed decision-making, and scalable growth. Advantages of implementing dairy ERP software to automate operations.

Improved operational efficiency

ERP integrates procurement, production, inventory, and finance into a single system. Automated workflows reduce manual effort and process delays. This improves coordination across departments and enhances overall operational speed.

Reduced manual errors and losses

Automation eliminates data inconsistencies caused by manual entries. Accurate recording of quantities, quality parameters, and transactions reduces wastage and financial discrepancies. This leads to better cost control and higher profitability.

Better decision-making with real-time data

ERP provides real-time visibility into operations and financial performance. Centralized dashboards and reports to make faster, data-driven decisions. This helps management respond proactively to operational challenges.

Stronger farmer and distributor relationships

Timely payments, accurate records, and transparent processes improve trust with farmers and distributors. ERP ensures consistency in pricing, settlements, and order fulfillment. This strengthens long-term supply chain relationships.

Scalability for business growth

ERP supports business expansion without increasing operational complexity. New locations, productions, and volumes can be managed within the same system. Standardized processes ensure consistent performance as the business grows.

Future of dairy automation with ERP and digital technologies

The global ERP market is projected to reach approximately $52 billion by 2025, with a compound annual growth rate (CAGR) of 4.48% from 2024 to 2028. The future of dairy automation lies in combining ERP systems with advanced digital technologies to achieve greater efficiency, accuracy, and transparency across the value chain. Here is how the future of dairy automation utilizing ERP and digital technologies looks.

IoT and sensor integration will enable real-time monitoring of milk quality, temperature, equipment performance, and cold storage conditions. This data, integrated with ERP, will help prevent spoilage, reduce downtime, and ensure consistent product quality.

AI-driven demand forecasting and quality analysis will allow dairy businesses to predict demand more accurately, optimize production planning, and reduce inventory waste. AI can also identify patterns and deviations early, improving yield and compliance.

Blockchain for traceability and transparency will strengthen end-to-end traceability by creating tamper-proof records from milk collection to final delivery. This enhances food safety, regulatory compliance, and consumer trust.

Conclusion

Automation has become essential for dairy businesses striving to improve efficiency, quality, and profitability in an increasingly competitive environment. Manual processes and disconnected systems limit visibility, increase losses, and restrict growth. ERP software designed for the dairy industry addresses these challenges by integrating procurement, production, inventory, quality, and finance into a single unified platform.

Implementing a dairy ERP solution can help automate processes, gain complete control, ensure regulatory compliance, strengthen relationships with farmers and distributors, and make data-driven decisions. Master Software Solutions specializes in one-stop ERP services for the dairy industry. Contact us today to discuss your project scope.