Fresh dairy products do not wait, and neither do your customers. Every delayed delivery, temperature deviation, or inventory mismatch has a direct impact on product quality, compliance, and profitability. Yet, many businesses still rely on disconnected systems and manual coordination to manage logistics and distribution.

Start by asking yourself a few questions, like

- Are you always confident about the location of your dairy products at any given moment?

- How often do spoilage, route inefficiencies, or last-minute order changes disrupt your distribution plans?

- Can your current systems support faster deliveries without increasing costs?

The dairy industry is highly perishable, precise, and regulated, making logistics excellence crucial. This is where a dairy ERP system becomes a game-changer. Unifying data from inventory, transportation, cold chain monitoring, and distribution into a single intelligent platform. This enables faster, safer, and more efficient product movement throughout the supply chain.

Table of Contents

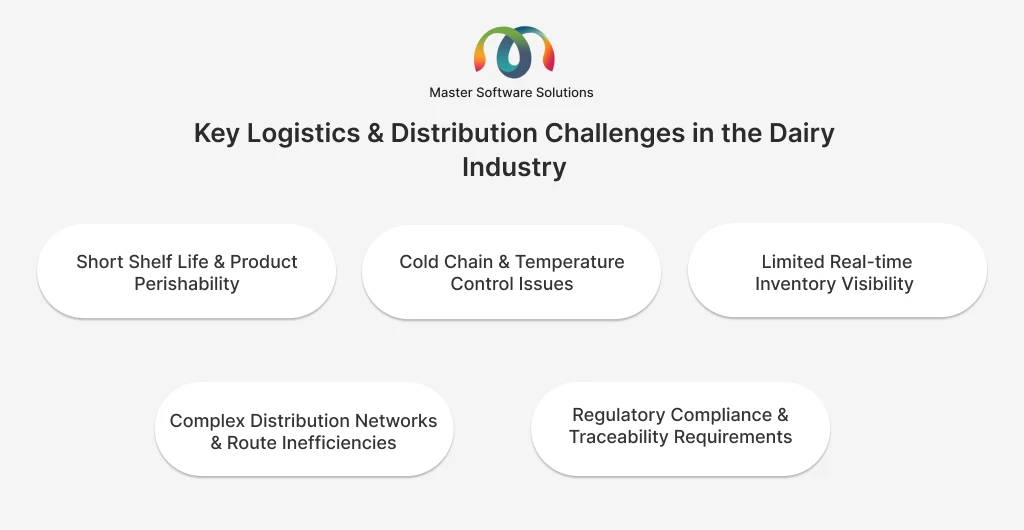

Key logistics and distribution challenges in the dairy industry

The dairy industry operates under some of the most demanding logistics and distribution conditions. Perishable products, strict quality standards, and complex supply networks create operational challenges that directly impact profitability and customer trust. Here are the major logistics and distribution challenges faced by the dairy industry.

Short shelf life and product perishability

Dairy products have limited shelf lives and require fast, uninterrupted movement across the supply chain. Delays in dispatch, inefficient loading, or slow deliveries directly increase the risk of spoilage. This leads to higher product wastage and write-offs, increased product returns from distributors and retailers, and pressure on production planning and reprocessing.

Cold chain and temperature control issues

Maintaining consistent temperature across storage, transportation, and last-mile delivery is complex, especially when monitoring is manual or siloed. Disruptions in the cold chain and issues of temperature control can lead to quality degradation, rejected shipments, regulatory non-compliance risks, and damage to brand reputation due to inconsistent product quality.

Limited real-time inventory visibility

The lack of centralized, real-time inventory data across plants, warehouses, and distribution centers results in inaccurate stock positions. Ineffective inventory management can lead to overstocking of slow-moving SKUs, stockouts of high-demand products, and inefficient warehouse utilization.

Complex distribution networks and route inefficiencies

Dairy distribution involves multiple delivery locations, frequent small shipments, and tight delivery windows. Manually planning routes can lead to longer delivery cycles, higher fuel consumption, increased logistics costs, and delayed deliveries, impacting customer satisfaction.

Regulatory compliance and traceability requirements

Strict food safety and quality regulations require end-to-end traceability of dairy products, from batch production to final delivery. This increases the risk of penalties and failed audits. It also slows down recall processes and increases the operational costs. There is limited visibility during quality incidents.

What is a dairy ERP system?

A dairy ERP (Enterprise Resource Planning) system is an industry-specific software solution designed to manage and integrate the end-to-end operations of dairy businesses, from milk procurement and production to inventory, logistics, distribution, and financial management.

Unlike generic ERP platforms, a dairy ERP system addresses the unique challenges of the dairy industry, including product perishability, cold chain requirements, batch traceability, regulatory compliance, and demand variability. It provides a centralized, real-time view of operations, enabling better control, visibility, and decision-making across the dairy value chain.

Key functional areas covered by dairy ERP

- Milk procurement and collection management: Farmer payments, quality testing, and procurement tracking.

- Production and processing management: Batch processing, yield management, and recipe control.

- Inventory and warehouse management: Real-time stock visibility, FIFO/FEFO handling, and expiry tracking.

- Logistics and distribution management: Route planning, fleet tracking, and delivery optimization.

- Quality control and traceability: Batch-wise tracking, recalls, and compliance reporting.

- Finance and accounting: Costing, invoicing, taxation, and financial reporting.

Role of dairy ERP in streamlining logistics operations

Logistics operations in the dairy industry demand precision, speed, and continuous quality assurance. A dairy ERP system acts as a centralized control layer, integrating inventory, transportation, and cold chain data into a single, real-time platform. This integration enables dairy enterprises to reduce wastage, improve delivery performance, and maintain product integrity throughout the distribution lifecycle. Here is how dairy ERP streamlines logistics operations in dairy businesses.

Inventory management and stock optimization

A dairy ERP system provides real-time inventory visibility throughout production plants, cold storage facilities, warehouses, and distribution centers. It tracks inventory at SKU, batch, and expiry date levels, ensuring accurate stock positions at all times. You can implement FIFO/FEFO inventory management strategies to prioritize the dispatch of near-expiry products.

The system enables batch-wise tracking for complete traceability. It also automatically triggers replenishment based on demand and stock thresholds. The inventory management can be integrated with production planning to align output with demand.

How do inventory management and stock optimization impact operations?

- Reduces product spoilage and expiry-related losses.

- Improves warehouse utilization and faster picking and dispatch.

- Better coordination between production, storage, and distribution teams.

Transportation and route planning

Dairy ERP systems automate transportation planning by analyzing order volumes, delivery locations, vehicle capacity, and delivery windows, replacing manual scheduling with data-driven route optimization.

The ERP system automates route planning and load optimization. You can manage and track fleet and vehicle capacity. The system enables real-time shipment tracking and delivery statuses. You can also integrate the ERP for the dairy industry, GPS, and fuel management systems.

How does transportation and route planning with ERP impact operations?

- Reduces transportation costs and fuel consumption.

- Improves vehicle utilization and reduces empty or underloaded trips.

- Ensures faster, more reliable deliveries to distributors and retailers.

Cold chain monitoring and quality control

Maintaining temperature consistency is critical in dairy logistics. A dairy ERP system integrates with IoT sensors and quality monitoring tools to track temperature, humidity, and handling conditions throughout storage and transportation.

The system enables businesses to monitor temperature in real time across cold storage and transit. The system automates alerts for temperature deviations. You can implement various inspection checkpoints at dispatch and delivery. The dairy ERP software enables digital record quality for audits and compliance. These records can be accessed at any point in time.

How do cold chain monitoring and quality control impact operations?

- Early detection and resolution of quality risks.

- Reduces shipment rejection and customer complaints.

- Stronger compliance with food safety regulations.

Enhancing distribution efficiency with dairy ERP

Efficient distribution is critical to ensuring product freshness, meeting customer demand, and maintaining profitability in the dairy industry. A dairy ERP system enables end-to-end coordination across demand planning, order fulfillment, distributor management, and regulatory compliance, creating a faster, more reliable, and more transparent distribution network. Here is how a dairy ERP system can enhance distribution efficiency.

Demand forecasting and order management

A dairy ERP system leverages historical sales data, seasonality, promotions, and market trends to generate accurate demand forecasts. This allows dairy businesses to align production, inventory, and distribution with actual market needs.

The platform enables advanced demand forecasting models based on both real-time and historical data. It automates sales order management across channels. You can dynamically allocate inventory based on demand priority. You can also integrate production and dispatch planning with an ERP system.

How do demand forecasting and order management enhance the dairy distribution process?

- Reduces overproduction and inventory holding costs.

- Improves order fulfillment accuracy and speed.

- Better responsiveness to demand fluctuations.

Distributor and channel partner management

Dairy ERP systems offer a centralized platform for managing distributors, wholesalers, retailers, and institutional customers. They ensure transparency, consistency, and performance monitoring across all channel partners.

The system enables efficient management of centralized distributor master data. Distributors have real-time visibility into their orders, inventory, and deliveries. You can track delivery performance and monitor SLAs. The dairy ERP software automates pricing, discounts, and commission management.

How do distributor and channel partner management enhance the dairy distribution process?

- Improves coordination and communication with channel partners.

- Faster order processing and reduced disputes.

- Better distributor accountability and performance optimization.

Compliance, traceability, and recall management

Dairy ERP systems enable full traceability by tracking each product batch from milk procurement to final delivery. This ensures that food safety regulations are followed and that quality incidents are addressed promptly.

The system enables batch and lot-level traceability across the supply chain. It automates compliance documentation and audit reports. This allows businesses to identify real-time recalls and executions. You can track quality incidents and conduct a root-cause analysis.

How do compliance, traceability, and recall management enhance the distribution process?

- Faster and more precise product recalls.

- Reduces financial and reputational risks.

- Increases confidence during audits and inspections.

Business benefits of implementing a dairy ERP system for logistics and distribution

Implementing a dairy ERP system enables dairy enterprises to transform logistics and distribution from cost-intensive, reactive functions into data-driven, performance-oriented operations. The dairy ERP centralizes processes and provides real-time visibility, delivering measurable business value across the supply chain. Here are the business benefits of implementing a dairy ERP for logistics and distribution.

Reduces product wastage and spoilage

A dairy ERP system significantly reduces product wastage by providing real-time visibility into inventory levels, batch details, and expiry dates across all storage and distribution points. With FIFO and FEFO-based dispatch rules and integrated cold-chain monitoring, dairy businesses can prioritize the movement of near-expiry products and quickly respond to temperature deviations. This proactive control minimizes spoilage, reduces write-offs, and improves overall product yield, directly protecting margins in a highly perishable supply chain.

Lower logistics and transportation costs

Automating route planning, load optimization, and fleet scheduling with a dairy ERP eliminates inefficiencies associated with manual transportation planning. As a result, dairy companies achieve better vehicle utilization, lower cost per delivery, and improved cost-to-serve across their distribution network.

Improved delivery performance and customer service

A dairy ERP system synchronizes order management, inventory availability, and dispatch planning within a single platform, enhancing delivery reliability. Real-time tracking of orders and shipments enables logistics teams to identify delays early and take corrective actions. This leads to consistent on-time, in-full deliveries, fewer disputes with distributors and retailers, and higher customer satisfaction, which is an essential differentiator in competitive dairy markets.

Enhanced inventory and working capital efficiency

Accurate demand forecasting and real-time stock visibility provided by ERP software for the dairy industry help maintain optimal inventory levels. Aligning production and distribution with actual market demand enables businesses to avoid excess stock and prevent stockouts. This balance reduces inventory holding costs, improves cash flow, and frees up working capital that can be redirected toward growth initiatives or operational improvements.

Stronger compliance and risk management

Dairy ERP systems capture batch-level data from procurement through last-mile delivery, enabling end-to-end traceability. Automating compliance and audit-ready reports reduces manual efforts and errors, while real-time recall capabilities allow businesses to identify and isolate affected products. This level of control minimizes regulatory risk, lowers recall costs, and safeguards brand reputation in a tightly regulated industry.

Greater operational visibility and decision-making control

The system consolidates logistics, inventory, transportation, and quality data into centralized dashboards, providing management with a single source of truth. This visibility enables faster decision-making, proactive issue resolution, and stronger coordination across departments. Leaders can monitor KPIs in real-time, identify performance gaps, and continuously optimize logistics and distribution processes.

Scalable and future-ready logistics operations

As your dairy business grows, expanding into new markets or introducing new product lines, a dairy ERP system scales seamlessly to support increased complexity. Its standardized processes, configurable workflows, and integrated capabilities allow companies to add distribution locations, channel partners, and volumes without operational disruption. This scalability ensures that logistics and distribution operations remain efficient, controlled, and future-ready.

Future of dairy logistics and distribution with ERP systems

The future of dairy logistics and distribution will be defined by speed, intelligence, transparency, and resilience. As consumer expectations rise and regulatory requirements become more stringent, dairy enterprises will increasingly rely on advanced ERP systems to transform logistics from a reactive cost center into a strategic, value-driven function. Here are a few technologies that will define the future of dairy logistics and distribution.

AI-driven and predictive logistics planning

Next-generation dairy ERP systems use AI and advanced analytics to forecast demand, optimize inventory, and anticipate logistics risks. Analyzing historical data, seasonality, and market trends with ERP software shifts reactive logistics planning to predictive. This helps dairy businesses reduce wastage, prevent stockouts, and maintain consistent service levels even during fluctuations in demand.

IoT-enabled cold chains and smart distribution networks

Integrating IoT sensors with dairy ERP systems enables real-time monitoring of temperature and transit conditions across the cold chain. Continuous data flow enables instant alerts and corrective actions in case of deviations. This ensures product quality, reduces spoilage, and strengthens compliance with food safety regulations throughout storage and distribution.

Real-time visibility and autonomous decision-making

Future dairy ERP systems will deliver end-to-end visibility across production, warehousing, and distribution. Centralized dashboards will enable logistics teams to monitor shipments, inventory, and partner performance. Built-in decision-support tools will recommend corrective actions, such as route adjustments or inventory reallocation, based on live operational data.

Greater integration across the dairy ecosystem

Dairy ERP systems will increasingly connect suppliers, logistics partners, distributors, and retailers on a single digital platform. For dairy enterprises and cooperatives, it provides greater transparency and stronger collaboration across the entire value chain.

Cloud-based, scalable, & agile ERP architectures

Cloud-native dairy ERP solutions enable faster deployment, easier scalability, and lower total cost of ownership. Businesses can utilize these systems to expand distribution networks, add channels, and manage higher volumes without worrying about infrastructure constraints. Continuous updates ensure access to new features while maintaining operational continuity.

Sustainability and cost optimization as core objectives

Future dairy ERP systems will embed sustainability into logistics planning through optimized routes, reduced wastage, and energy-efficient operations. These initiatives help lower emissions and operating costs while supporting regulatory and ESG goals. Sustainability metrics will become standard KPIs within ERP-driven logistics strategies.

What sets Master Software Solutions apart from other ERP implementation companies?

Master Software Solutions is a renowned ERP consulting company that offers comprehensive, one-stop ERP services, including implementation, consulting, migration, customization, configuration, and ongoing support. This end-to-end approach ensures seamless execution, faster adoption, and long-term system performance for dairy businesses.

We leverage industry-leading ERP platforms such as Odoo and Microsoft Dynamics 365 to deliver highly customized ERP solutions tailored to the unique operational needs of the dairy industry. As an official Odoo partner, Master Software Solutions brings deep platform expertise, combined with strong domain knowledge in dairy logistics and distribution.

What further sets Master Software Solutions apart is its development of specialized Odoo plugins designed specifically for dairy logistics and distribution. These include advanced route planning and route optimization plugins that help dairy businesses to streamline deliveries, reduce transportation costs, and improve on-time performance. Book a consultation call to discuss your dairy business requirements.