Manufacturing businesses are becoming more sophisticated as technology advances. They are using AI-powered machines and tools to manage those operations. If you are also a manufacturing business and have not implemented tools, it is high time you consider doing so.

The global manufacturing market is estimated to reach USD 9.1 trillion in 2029 at a 1.09% CAGR. With such industry growth, coping with competition requires you to be more efficient and productive while reducing operational overheads. This is where Odoo ERP software comes into the picture.

Table of Contents

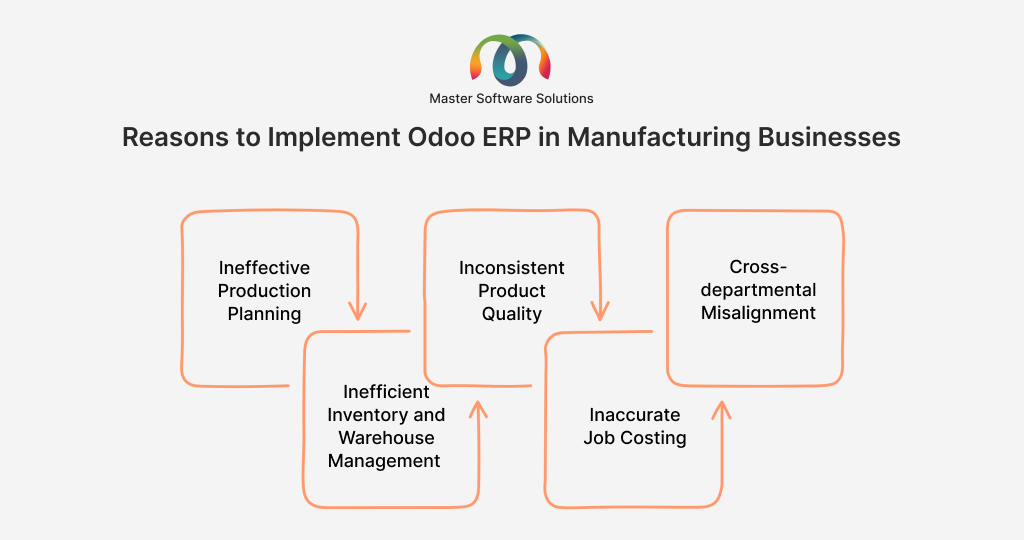

Reasons to implement Odoo ERP in manufacturing businesses

Manufacturing businesses that operate without an ERP system often have lower productivity and profitability, and the operational costs are high. They are commonly caused by time-consuming and error-prone manual operation management. Here are the common reasons you should consider implementing Odoo ERP in manufacturing businesses:

Ineffective production planning

The inability to calculate the exact raw materials or components required without real-time integration of inventory, sales orders, and Bill of Materials (BoM) leads to excess purchasing or production stoppages. Relying on gut feeling for scheduling work orders against the machine and labor leads to production bottlenecks, idle time, and the inability to give reliable lead times. There is no automatic system to recalculate the production schedule and notify affected departments, resulting in a reactive and costly approach.

Inefficient inventory and warehouse management

Manually tracking receipts, issues to the shop floor, and finished goods transfer can lead to discrepancies between the physical count and system records. These discrepancies are expensive and disrupt physical inventory counts or cycle-counting efforts. Manually tracking the product’s full history is prone to errors, resulting in critical failure points for regulatory compliance, quality control, and potential product recalls. Without a system-guided process, material movement on the shop floor is disorganized, leading to delays as workers search for components.

Inconsistent product quality

Manual quality checks and recording findings lead to delays in identifying recurring defects. Without centralized systems, it is difficult to link a specific product defect with the originating production run, material batch, or work center. Manually maintaining audit trails, certification documents, and regulatory reports is time-consuming and prone to errors, increasing the risk of fines or license violations.

Inaccurate job costing

It is difficult to calculate the true cost of production accurately when the data is siloed. Manual time-tracking and inventory issue records are flawed. Without precise, real-time job costing, manufacturers are unable to determine which products are profitable, leading to poor pricing and product focus decisions.

Cross-departmental misalignment

The sales team, with outdated inventory and capacity information, promises delivery dates that the production team cannot meet. This damages customer trust and leads to lower On-Time-In-Full (OTIF) delivery rates. Managing multiple versions of the Bill of Materials (BOM) and routing is difficult, resulting in outdated instructions or incorrect components for a job.

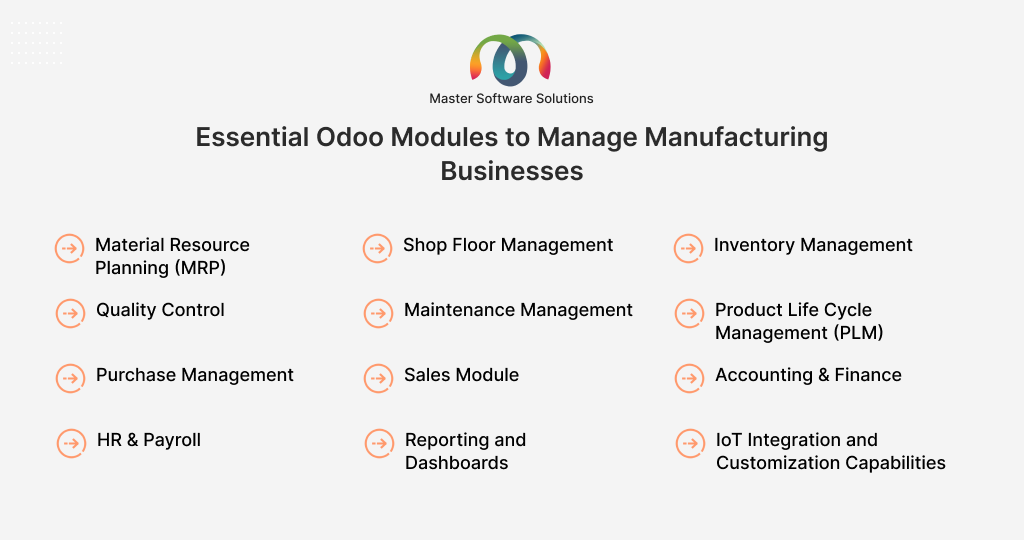

Essential Odoo modules to manage manufacturing businesses

As we know, Odoo ERP software offers a wide range of business applications, but not all of them are specifically tailored to manufacturing businesses. Here are the Odoo modules specific to your manufacturing business:

Material Resource Planning (MRP)

The MRP module is the central component of manufacturing operations. It focuses on planning, scheduling, and controlling the product production. This module ensures that the materials are available when needed and that production capacity is used efficiently to meet customer demand. The key functions of the MRP module are

- Creating Bills of Materials (BOMs) – Defining the list of components or raw materials needed to manufacture a product.

- Managing work orders – The instructions for performing manufacturing operations at a specific work center.

- Scheduling – Planning when and where manufacturing should happen based on material availability and capacity.

- Manufacturing orders – The request to manufacture a defined quantity of a product.

Shop floor management

This module is integrated with the MRP module, which provides tools for real-time execution and monitoring of operations on the factory floor. Shop floor management can help you improve production data accuracy, reduce administrative tasks for workers, and provide managers with a clear, live view of production progress. The key functions of the shop floor management are:

- Operator interface – A simple, tablet-based interface for workers to start/stop work orders, log time, register production quantities, and record scrap.

- Barcode/QR code scanning – Used for quick identification of components, work orders, and finished goods.

- Instruction display – Showing technical drawings, documents, or step-by-step instructions to the operator.

Inventory management

The inventory module helps manage the movement and storage of all types of inventory, including raw materials, work-in-progress (WIP), and finished goods. Efficient inventory management helps prevent stockouts of essential components, optimize warehouse space, and provides accurate cost data for manufacturing. The key functions of the inventory module are:

- Stock location management – Tracking inventory across different warehouses or bin locations.

- Receipts and deliveries – Progressing incoming materials from suppliers and outgoing finished products to the customers.

- Inventory valuation – Calculating the monetary value of stock.

- Traceability – Tracking the entire history (lot/serial numbers) of a product or component.

Quality control

The quality control module of Odoo ERP establishes and enforces quality standards throughout the manufacturing process. This module ensures that products meet specifications, reduces waste, and aids in continuous process improvement. The key functions of the quality control module are:

- Quality checks/points – Defining mandatory quality inspections at specific stages, such as incoming material inspection and in-progress inspection.

- Quality alerts – Reporting defects or non-conformities with required corrective actions.

- Statistical process control (SPC) – Monitoring production to ensure it stays within acceptable quality limits.

Maintenance management

The maintenance module helps manage and maintain machinery and equipment used in the production process. This module can minimize costly production downtime, extend the lifespan of assets, and ensure reliable machine performance. The key functions of maintenance management

- Preventive maintenance – Scheduling routine inspections and service to prevent breakdowns.

- Corrective maintenance – Handling repair requests (breakdowns) quickly.

- Equipment tracking – Maintaining a history of service, parts used, and downtime for each piece of machinery.

- Maintenance requests – Allowing operators to report issues quickly.

Product life cycle management (PLM)

The PLM module manages the evolution of the product from conception through design, manufacturing, service, and retirement. The module ensures that everyone is working with the latest product specifications, avoiding costly errors due to outdated designs or procedures. The key functions of the product life cycle management are:

- Document management – Storing and version-controlling engineering drawings, specifications, and manufacturing procedures.

- Engineering change orders (ECOs) – Systematically managing changes to BOMs and routings, ensuring all departments (purchasing and manufacturing) use the correct version.

- Product versioning – Tracking different revisions of a product.

Purchase management

The purchase module of Odoo ERP handles procurement of all necessary raw materials, components, and indirect supplies for the business. This module ensures a steady supply of materials, helps negotiate better prices, and prevents production delays due to material shortages. The key functions of purchase management are

- Purchase orders – Creating and sending formal requests for materials to suppliers.

- Request for Quotation (RFQ) – Request pricing from several vendors.

- Vendor management – Maintaining supplier details and price lists.

- Automatic reordering – Triggering POs based on minimum stock levels or MRP demands.

Sales module

The sales module manages the entire order-to-cash cycle, from customer inquiry to confirmed sale. The key functions of the sales module are:

- Quotations and sales orders (SOs) – Creating, sending, and confirming customer orders.

- Pricing and discounts – Managing complex price lists and special offers.

- Integration with MRP – Sales orders automatically create demand for finished goods, driving the MRP schedule.

- Customer relationship management (CRM) – It is a separate module, but it is closely linked to the sales module. This helps track interactions with leads and customers.

Accounting & finance

The accounting and finance module can record, process, and generate reports on all financial transactions. This module accurately determines product cost and profitability, manages cash flow, and ensures legal/tax compliance. The key functions of the accounting and finance module are:

- General ledger – Tracks all your revenues and expenses.

- Accounts payable (AP) – Manages payments to the suppliers (from the Purchase module).

- Accounts receivable (AR) – Manages payments from customers (From the Sales module).

- Cost accounting – Tracks the detailed cost of manufacturing a product (materials, labor, overhead)

- Budgeting and financial reporting – Generating profit & loss, balance sheet, etc.

HR & payroll

The HR & payroll module manages workforce, employee information, and compensation. This module calculates manufacturing labor costs and ensures employee compliance. The key functions of the HR and payroll module are

- Employee records – Stores personal data, job roles, and contact information.

- Time tracking – Records hours worked, particularly on the shop floor (linked to work orders).

- Leave/absence management – Approves and tracks employee time off.

- Payroll processing – Calculate and issue wages and salaries (crucial for accurate labor costing in manufacturing).

Reporting and dashboards

The reporting and dashboards module aggregates data from all the above modules to provide clear, actionable business intelligence. This enables management to quickly identify bottlenecks, analyze trends, and make data-driven decisions to optimize the business. The key functions of the reporting module are:

- Pre-built reports – Standard reports on inventory valuation, sales performance, cash flow, and production efficiency.

- Custom dashboards – These enable users to design their own views based on key performance indicators (KPIs), such as production volume, on-time delivery rates, and OEE (Overall Equipment Effectiveness).

- Real-time analytics – Provides up-to-the-minute data for faster decision-making.

IoT Integration and customization capabilities

These represent the platform’s ability to connect with the physical world and adapt to unique business needs.

IoT integrations

- Function – Connecting physical devices, such as machinery, sensors, and quality measurement tools, directly to Odoo. This allows for automated data collection.

- Manufacturing value – Enables real-time machine monitoring, including automatically logging runs and output, triggering automatic maintenance requests based on sensor data, and eliminating manual data entry for increased accuracy and OEE calculation.

Customization capabilities

- Function – Odoo is an open-source platform that enables users to develop custom modules, modify existing forms/logic, and integrate with external systems via APIs.

- Manufacturing value – A manufacturing business can tailor the system to its unique processes, proprietary calculations, or industry-specific compliance requirements that are not covered by the standards of off-the-shelf software.

How does Master Software Solutions help your manufacturing business?

Master Software Solutions is an Odoo-certified partner that offers complete Odoo solutions for manufacturing, retail, e-commerce, logistics, and warehousing, as well as subindustries such as metal fabrication, dairy, and bottled water. We offer Odoo ERP services, including:

- Odoo Consulting Services

- Odoo Implementation Services

- Odoo Customization Services

- Odoo Multi-platform Integration Services

- Odoo Migration Services

- Odoo Web Design and Development Services

- Odoo Module Development Services

- Odoo Support and Maintenance Services

If you are a manufacturing company seeking Odoo implementation, contact us to see how we can assist.