Metal fabrication and job shops operate in a demanding environment where every cut, bend, and weld must be precise, cost-efficient, and delivered on time. Managing complex workflows such as quoting, nesting optimization, raw material tracking, production scheduling, and shop floor monitoring can become overwhelming without the right system. Relying on spreadsheets or disconnected tools often results in wasted materials, machine downtime, and missed deadlines.

This is where laser-cutting ERP software makes the difference. The ERP for fabrication is specifically designed for job shops, which connect quoting, CAD/CAM, nesting, material management, scheduling, and job tracking into a single seamless platform. This blog covers everything you need to know about laser cutting ERP software and how it is revolutionizing the metal fabrication and job shops.

Table of contents

What is a laser cutting ERP?

A laser cutting ERP software is a specialized software system designed for metal fabrication companies and job shops that use laser cutting machines. It centralizes and automates core business processes, such as quoting, material management, production scheduling, nesting optimization, shop floor tracking, and invoicing into a single platform.

Unlike generic ERP systems, a metal fabrication ERP software is tailored to the unique needs of job shops, offering features such as CAD/CAM integration, real-time machine monitoring, and remnant tracking. This helps shops minimize material waste, improve machine utilization, ensure on-time deliveries, and maintain complete visibility across operations.

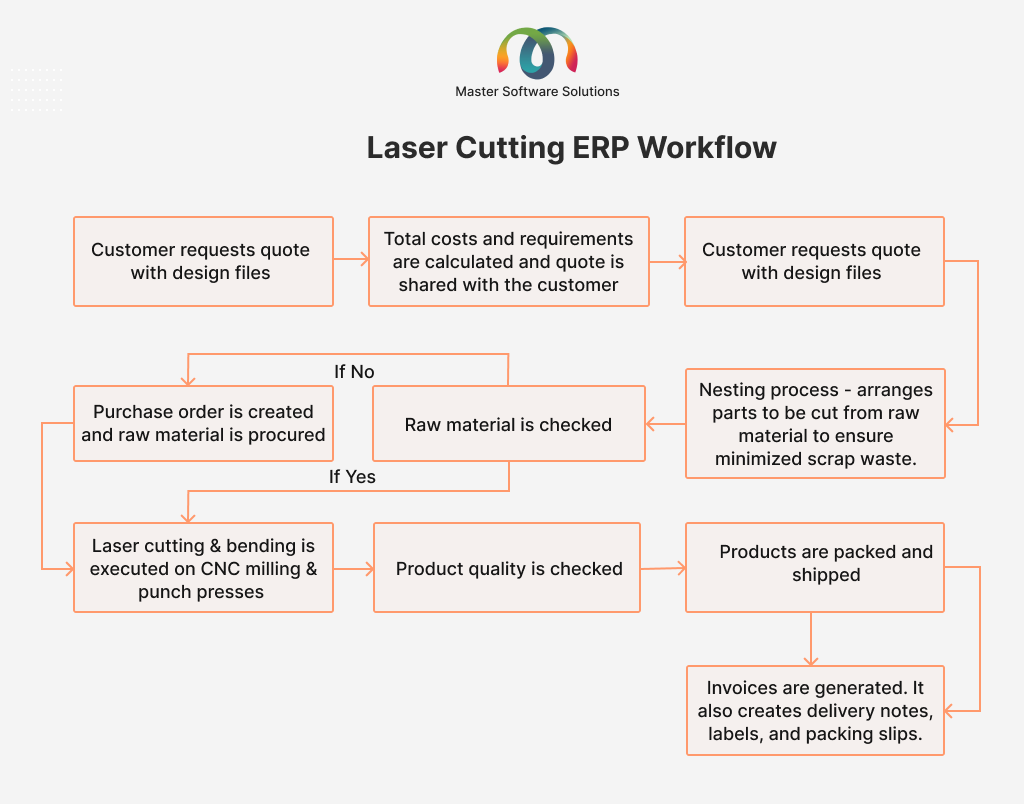

Laser cutting ERP workflow for metal fabrication and job shops

1. Customer inquiry and quoting

Customers request a quote with design files (in formats like DXF, DWG, etc.) or job specifications. The ERP system calculates material usage, nesting efficiency, cutting time, labor, and overhead. Based on these factors, a precise quote is generated and shared with the customer.

2. Order creation and confirmation

Once approved, the quote is converted into a sales order with the ERP. The job details, materials, and delivery deadlines are stored in the system.

3. CAD/CAM integration and nesting

The ERP integrates with CAD/CAM software for the nesting process. Nesting optimization is performed to minimize waste and utilize remnants. Machine-ready programs (NC code) are generated and sent to the laser cutting machines for laser cutting.

4. Material allocation and inventory management

The ERP software checks available stock and allocates raw sheets/plates. If the material is insufficient, purchase requisitions are auto-generated. Remnants are tracked and logged for future use.

5. Production scheduling and job assignment

Jobs are scheduled based on machine availability, workload, and delivery deadlines. The operators receive clear job instructions via the ERP-linked shop floor terminals.

6. Laser cutting and floor shop execution

The machines execute the cutting program. The operators can log progress, downtime, or issues in real-time. The ERP continuously tracks production status and machine utilization.

7. Quality control and inspection

The finished parts undergo inspections as per defined tolerances and industry standards. Any non-conformance is logged along with corrective actions tracked.

8. Packaging and delivery

The ERP system creates delivery notes, labels, and packing slips. You can also schedule logistics to ensure on-time delivery.

9. Invoicing and payment

Once the delivery is confirmed, the ERP for the laser cutting industry automatically generates invoices. Payments (advance, milestone, or post-delivery) are tracked in the finance module.

10. Reporting and analytics

The managers access dashboards for job profitability, material utilization, machine efficiency, and customer delivery performance. The data-driven insights help optimize business growth.

Challenges faced by metal fabrication and job shops without an ERP system

Running a metal fabrication business or job shop involves hurdling between multiple moving parts, including quoting, material procurement, nesting, production scheduling, and delivery. Metal fabrication and job shops often manage laser cutting and bending services manually or across disconnected tools without ERP software, causing inefficiencies and costly errors. Here are the common challenges they face without an ERP system:

Manual batch & sub-batch management makes tracking material & defect detection difficult, leading to material losses & higher rework & scrap costs.

Manual batch and sub-batch management make it difficult to track materials and identify defects at the right stage. Without clear visibility, fabricators struggle to trace defective parts back to their source, resulting in unnecessary material loss, increased rework, and higher costs.

Capturing, linking, and carrying heating numbers & MTRs through operations manually leads to errors, lost traceability, and audit risks.

Heat numbers and Mill Test Reports (MTRs) are vital for compliance and customer assurance in fabrication. When managed manually, capturing and linking these documents across inventory and production is prone to errors. Lost or mismatched MTRs break traceability, making it hard to meet audit requirements. This creates compliance risks and erodes customer confidence.

Tariff-driven price fluctuations make bulk repricing error-prone, causing revenue loss, compliance risks, & customer disputes.

Tariff changes frequently impact raw material and product costs, forcing businesses to re-price in bulk. Manual re-pricing is complex and prone to errors, often causing mismatches between quotes, invoices, and actual costs. Such errors result in revenue leakage and compliance issues. They also spark customer disputes, damaging trust and profitability.

Manually calculating material usage, nesting efficiency, or machine time can lead to underpricing and overpricing jobs.

Manually calculating material usage, nesting efficiency, or machine time often results in inaccurate quotes. If underpriced, the shop absorbs hidden costs and loses profits. If you are overpriced, potential customers turn to competitors. Over time, this inconsistency hurts both profitability and reputation.

Manually transferring design files to the machine leads to production delays, errors, and inefficient nesting.

Manually transferring design files to machines not only delays production but also increases the chances of errors, including wrong file versions, missing parameters, and inefficient nesting layouts. This results in increased rework, wasted materials, and slower turnaround times, ultimately affecting delivery schedules.

Manual production tracking is error-prone and makes monitoring machine utilisation difficult, resulting in increased downtime.

Manual shop floor tracking makes it difficult to monitor machine utilization and operator performance. Breakdowns or delays often go unnoticed until it’s too late, resulting in prolonged downtime and missed deadlines. This lack of visibility prevents managers from making quick, corrective decisions.

Manual inventory and procurement are prone to errors, leading to understocking & overstocking & poor customer experience.

Manual inventory tracking is prone to errors, like double entries, missed updates, or outdated records. This often leads to stockouts, delayed jobs, or overstocking, tying up working capital in unused materials. Both stockouts and overstocking can reduce operational efficiency and lead to poor customer experiences.

Making adjustments to designs in an ongoing manufacturing process manually is impossible, increasing scrap and costs.

In a traditional setup without ERP integration, making adjustments to the designs during an ongoing manufacturing process is nearly impossible. When a customer requests a last-minute change or operators identify an error after production starts, they usually stop the job, update the design files manually, and restart the cutting process. This leads to production delays, wasted raw materials from partially processed sheets, and increased scrap and costs.

Features of ERP for metal fabrication and job shops

Metal fabrication and job shops operate in a fast-paced environment where efficiency, precision, and cost control are critical for success. An ERP for the laser cutting industry specifically designed for fabrication, bringing together all aspects of operation, such as quoting, production, material management, quality control, and delivery, into one integrated platform. Here are the benefits of implementing an ERP system in your metal fabrication and job shops:

Batch and sub-batch management provide accurate material tracking, reduce scrap & rework, and improve efficiency.

This feature enables job shops to accurately track raw materials as they move through production, ensuring complete visibility of each batch and sub-batch. Identifying defects early and linking them to specific batches reduces scrap and rework while improving overall operational efficiency.

Auto-assigning and MTR document management reduce manual errors, boost customer confidence, & ensure compliance.

The ERP system automatically assigns heat numbers and links MTR documents to inventory lots, preventing manual errors and keeping traceability intact throughout production. The system also provides reliable documentation, enabling businesses to meet industry compliance and build customer confidence.

Dynamic pricing engine for auto-update prices based on tariffs, protecting profit margins, reducing disputes, & saving time.

The ERP system offers a feature for dynamic pricing, which automatically updates product, raw material, and customer prices based on the tariff or price fluctuations. Automated price adjustments for raw materials and customers, in bulk, protect profit margins, minimize disputes with customers, and save time.

Quoting & estimations to create precise cost estimates based on the material type, thickness, nesting efficiency, labor & overheads.

The ERP system considers critical factors such as material type, thickness, nesting efficiency, labor, and overheads, allowing job shops to generate accurate cost estimates. This ensures competitive yet profitable pricing, while minimizing human errors and inconsistencies in quotes.

CAD/CAM integrations for smoother transfer of design files to CNC (Computer Numerical Control) laser cutting machines.

With built-in CAD/CAM integration, the system transfers design files directly to CNC (Computer Numerical Control) laser cutting machines, eliminating manual data entry, reducing setup time, and ensuring precise cuts without delays or versioning errors.

Nesting software integration to maximize material usage by arranging parts efficiently on sheets and tracking remnants for future use.

Integrating nesting software with ERP maximizes material usage. It arranges parts efficiently on raw sheets and automatically tracks remnants for future jobs. This reduces scrap, lowers material costs, and increases overall profitability. The system supports various manufacturing management strategies, such as make-to-order fabrication and make-to-stock fabrication.

Inventory and bill of material management for real-time stock level visibility, reducing the chances of stockouts & overstocking.

This metal ERP software provides real-time visibility into raw material, finished goods, and remnants. Bill of Materials (BOM) management tracks every component required for production. It allows shop jobs to manage and track batched inventory. The system also offers features that enable you to manage your metal fabrication subcontracting orders. This prevents stockouts, reduces over-purchasing, and ensures materials are always available for scheduled jobs.

Automated production planning and scheduling based on machine availability, workload balance, and delivery deadlines.

The system automates job handling based on machine availability, workload balancing, and delivery deadlines. This minimizes idle machine time, prevents production disruptions, and ensures smooth workflows across the shop floor.

Shop floor control for tracking live job status, downtime, and operator performance, identifying and resolving production issues.

ERP offers real-time monitoring of job progress, machine downtime, and operator performance. Managers can identify bottlenecks, address issues immediately, and improve machine utilization. This feature keeps production on track and meets deadlines.

Quality control & traceability to maintain inspection records, compliance documents, and batch traceability.

ERP has built-in Quality checks and compliance tracking. Shops can maintain inspection records, certification documents, and batch traceability, which are especially critical in industries like aerospace, automotive, and construction.

Order and delivery management streamlines the entire order-to-delivery process, linking production with logistics.

The ERP system links production with logistics, streamlining the process from order creation to final delivery. It generates delivery notes, packing slips, and dispatch schedules, ensuring customers receive accurate and on-time deliveries.

Reporting and analytics provide dashboards and reports on key metrics, identifying inefficiencies and making improvements.

Dashboards and advanced reporting tools provide insights into Key Performance Indicators (KPIs) such as machine efficiency, material utilization, job profitability, and customer delivery performance. This data empowers managers to identify inefficiencies and make informed, data-driven decisions.

Engineering change management to accommodate a change in design or a change in an ongoing manufacturing process.

Engineering change management is the ability of an ERP system to handle design modifications or adjustments in an ongoing manufacturing process without disrupting production. With ERP software for metal fabrication, engineering change management can seamlessly integrate the revised designs into the workflow. The updated files automatically sync with nesting, scheduling, and shop floor systems, ensuring operators work with the latest designs.

Benefits of implementing laser cutting ERP for metal fabrication and job shops

Adopting a laser cutting ERP for metal fabrication and job shops to streamline operations, cut down costs, and deliver high-quality products. Integrating every aspect of production, from quoting and design to manufacturing, quality checks, and delivery, ensures improved efficiency, profitability, and customer satisfaction. Below are the key benefits of implementing laser cutting ERP in metal fabrication and job shops:

Precise material tracking throughout production minimizes material loss, and early defect detection lowers overheads.

Moreover, ERP tracks raw materials accurately from raw stock to finished goods, ensuring that nothing is misplaced during the production process. Detecting defects early and linking them with specific batches or sub-batches reduces unnecessary scrap and rework, lowering costs and improving efficiency.

Build customer confidence through reliable MTR documentation and ensure accurate traceability with auto-assigning heat numbers.

Automated heat number assignment and centralized Mill Test Reports (MTR) enable businesses to maintain complete material traceability. Providing reliable, error-free MTR documentation ensures compliance with industrial standards, helping you build stronger customer confidence.

Automatic price adjustments based on tariffs protect profits and reduce customer disputes with consistent & accurate pricing.

Dynamic pricing in job shops’ ERP software automatically updates prices in line with tariffs and cost fluctuations. This ensures consistent and accurate pricing across quotes, orders, and invoices, protecting profit margins, reducing manual errors, and preventing customer disputes.

Accurate quoting & increased profitability with automated cost calculations, preventing underpricing or overpricing.

In metal fabrication, quoting involves multiple cost factors; for instance, material type and thickness, as well as cutting time, labor, overheads, and waste, all play a significant role. Manual calculations often result in underpricing (leading to losses) or overpricing (losing bids). An ERP automates these calculations by pulling data directly from the CAD/CAM files, inventory, and labor rates to generate precise quotes. This accuracy increases profitability and boosts credibility with customers.

Reduced material waste & cost savings with nesting optimization and remnant tracking, reducing scrap & purchasing costs & improving margin.

The ERP system integrates with nesting software to optimize parts arrangement, ensuring maximum sheet utilization. Moreover, they track usable remnants, which helps reduce unnecessary purchases. Consequently, this significantly lowers raw material expenses and, in turn, directly contributes to higher margins.

Seamless workflow integration with CAD/CAM integration, eliminating manual data entry, minimizing errors, & ensuring smooth coordination.

ERP can integrate CAD/CAM files directly into the workflow, feeding accurate data into nesting, scheduling, and machine programs. This ensures smoother collaboration between design and production, eliminates duplication, and reduces costly mistakes.

Streamlined inventory & procurement with automated POs and real-time stock updates, reducing the risk of over- & under-stocking.

The ERP software provides real-time visibility into stock levels and purchase orders when they reach the thresholds. Furthermore, it ties inventory directly to job requirements, ensuring that the right materials are always available when needed. This reduces downtime, prevents waste, and optimizes procurement cycles.

Seamless design modification adjustments in an ongoing manufacturing process, reducing scrap and minimizing downtime.

In metal fabrication, design changes often occur mid-production due to customer requests or engineering corrections. ERP systems with engineering change management let users modify workflows directly and instantly update nesting, scheduling, and machine programs. This reduces scrap, minimizes downtime, and ensures flexibility without halting operations.

Conclusion

Metal fabrication and job shops face unique challenges, and relying on manual processes or disconnected systems adds complexities, delays, and higher costs. A dedicated laser cutting ERP software for metal fabrication and job shops integrates quoting, CAD/CAM, nesting, production planning, shop floor control, inventory, and quality management into a single platform. This helps fabrication businesses and job shops to achieve greater accuracy, reduced waste, improved efficiency, stronger compliance, and higher customer satisfaction.

Master Software Solutions is an IT service provider that offers implementation, customization, and integration services for manufacturing ERP software. We provide custom solutions for various manufacturing industries, including fabricated metal, automotive parts & accessories, electronics, and chemicals & fertilizers. To meet your specific business workflow, we develop custom solutions using the Odoo ERP and Microsoft Dynamics 365 ERP platforms. To discuss your manufacturing business needs and see how we can assist, schedule a call.