In the dairy business, every drop counts. Yield isn’t about the quantity of milk processed, but it’s about maximizing product output at every stage, from collection and processing to packaging and distribution. However, many dairy businesses lose significant yield due to manual errors, inconsistent quality checks, poor inventory management, and a lack of production visibility.

A dairy ERP software directly addresses these challenges by offering end-to-end automation, real-time monitoring, and accurate forecasting. It ensures that raw milk is utilized efficiently from each production cycle. This explores yield in the dairy business, features of ERP that help manage yield, and its benefits.

What is yield in a dairy business?

Yield in the dairy business refers to the amount of usable product obtained from raw milk procured and processed. Yield index is a key performance indicator (KPI) that measures the efficiency with which milk is converted into finished dairy products.

Understanding yield in dairy production:

- Milk-to-Product Conversion Yield – How much cheese, butter, yogurt, or other products are produced from a given volume of milk? Example: 10 liters of milk produces 1 kg of cheese.

- Processing Yield – The efficiency of production lines—how much raw milk and ingredients are actually converted into sellable products versus lost in wastage, spillage, or spoilage.

- Nutritional Yield – The retention of key components such as fat, protein, and solids-not-fat (SNF) during processing. This ensures that valuable nutrients are not lost, helps improve product quality and consistency.

- Economic Yield – How much profit is generated from the milk supplied compared to operational costs? This looks at both output quantity and cost efficiency.

Yield in the dairy business determines the quantity and quality of finished dairy products from the raw milk supply while minimizing waste, losses, and costs.

How does dairy ERP help manage yield?

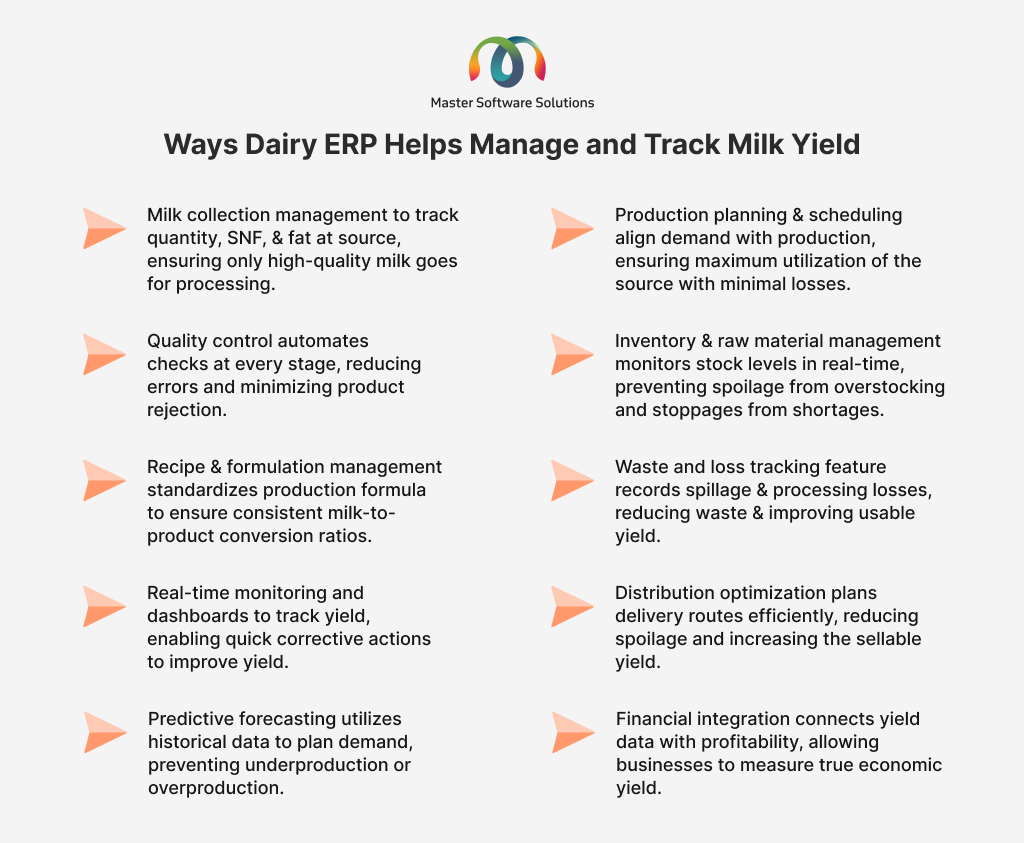

An ERP for the dairy industry helps manage yield by bringing together all the processes that directly impact the amount of usable product that can be produced from raw milk. The system offers various features and functionalities that can help improve overall yield while minimizing your overhead. Ways in which dairy ERP helps manage and track milk yield:

Milk collection management to track quantity, SNF, & fat at source, ensuring only high-quality milk goes for processing

Yield in a dairy business depends on the quality of the milk collected. A dairy ERP software helps track essential parameters such as quantity, fat content, and SNF (solids-not-fat) right at the collection point. Ensuring only high-quality milk enters processing enables businesses to achieve a better milk-to-product conversion ratio, minimize waste, and maintain consistent product output. This accurate monitoring at the source prevents low-grade milk from reducing yield and ensures that every litre collected provides maximum product output.

Production planning & scheduling align demand with production, ensuring maximum utilization of the source with minimal losses

Efficient yield depends on how well milk supply is matched with production needs. A dairy ERP system utilizes its production planning and scheduling module to align raw material availability with customer demand and processing capacity. This prevents underutilization, where milk goes unused, or overproduction, where excess product risks spoilage. The system optimizes batch sizes, production timelines, and resource allocation to ensure that every liter of milk collected is processed effectively, minimizing losses and maximizing yield across the production cycle.

Quality control automates checks at every stage, reducing errors and minimizing product rejection

Dairy yield management is more than just processing more milk; it is about ensuring that what is processed meets quality standards. ERP for dairy businesses automates quality checks at every stage, from milk intake to final packaging, by monitoring parameters like temperature, hygiene, fat, and SNF. This reduces human error and ensures compliance with safety regulations. The system helps catch issues early and minimize product rejection, increasing the proportion of sellable output and ensuring higher yield from the same raw milk supply.

Inventory & raw material management monitors stock levels in real-time, preventing spoilage from overstocking and stoppages from shortages

Raw material wastage due to overstocking or production halts because of shortages can significantly affect yield. Diary ERP solutions enable real-time monitoring of milk, additives, and packaging material to strike the right balance. This prevents the spoilage of perishable items and avoids production stoppages, ensuring continuous operations and optimal resource utilization. Ultimately, this consistency directly contributes to maximizing yield by reducing avoidable losses across the supply chain.

Recipe & formulation management standardizes production formula to ensure consistent milk-to-product conversion ratios

Yield in dairy production relies heavily on how effectively milk is converted into finished products, like cheese, butter, or yogurt. An ERP system manages and standardizes product formulations to ensure consistent fat and SNF. It helps control recipes and reduce variations in production processes, enabling dairy businesses to achieve predictable milk-to-product conversion ratios. This ensures that every liter of milk delivers the highest possible output, improving product quality and maximizing yield.

Waste and loss tracking feature records spillage & processing losses, reducing waste & improving usable yield

Unmonitored spillage, leakages, and line efficiencies can quietly reduce overall yield in dairy operations. This system tracks losses in real-time, recording where and how waste occurs during collection, processing, or packaging. The ERP system identifies recurring issues and bottlenecks, allowing businesses to take corrective actions to minimize avoidable losses. This proactive approach ensures that raw milk collected is converted into a marketable product, thereby increasing usable yield.

Real-time monitoring and dashboards to track yield, enabling quick corrective actions to improve yield.

Maximizing yield requires constant visibility into how milk is being processed and converted. An ERP software for the dairy business offers real-time dashboards that track yield metrics, including milk-to-product conversion ratios, wastage levels, and efficiency trends. With this real-time yield tracking, you can spot issues early, like unusual losses or production inefficiencies, and take corrective actions before they impact output. This continuous monitoring helps dairies maintain higher, more consistent yields from every batch.

Distribution optimization plans delivery routes efficiently, reducing spoilage and increasing the sellable yield

Yield is not confined to production, but it extends through the supply chain. A dairy ERP system optimizes delivery routes and schedules to ensure products reach distributors and retailers quickly and in adequate condition. This minimizes delays, handling errors, and spoilage during transit, and businesses can preserve product freshness and extend shelf life. Improved efficiency ensures that a larger share of the produced goods remains sellable, directly boosting overall yield.

Predictive forecasting utilizes historical data to plan demand, preventing underproduction or overproduction

Accurate forecasting is vital to protect yield from being lost to underproduction or overproduction. ERP for the dairy industry utilizes historical sales data, seasonal demand patterns, and market trends to predict future requirements with precision. This ensures that dairy businesses procure the right amount of raw milk and plan production accordingly. This also helps avoid excess output that risks spoilage and shortages, leaving milk underutilized, predictive forecasting safeguards yield, and maximizes the usable output from every liter.

Financial integration connects yield data with profitability, allowing businesses to measure true economic yield

Measuring yield is not just about tracking volumes, but it is about understanding how efficiently milk is converted into profits. The system connects yield data with financial records, enabling you to calculate the true economic yield of their operations. It can analyze production efficiency alongside costs, revenue, and margin to provide a clear picture of where profits are being maximized or lost. This integration ensures that yield improvements translate directly into stronger financial performance.

Conclusion

Master Software Solutions offers tailored dairy ERP solutions that consolidate all your business operations management into a single platform. It integrates features, including milk collection tracking, production planning, quality control, inventory management, and real-time analytics to reduce wastage, optimize resources, and maximize milk-to-product conversion ratios. This helps improve yield, consistent product quality, and higher profitability across the entire dairy value chain.