The dairy industry is one of the most dynamic and fast-moving sectors in the food and beverage industry, where efficiency, quality, and timely delivery are crucial to success. Dairy companies must manage everything from milk collection and production planning to distribution, sales, and compliance in an efficient manner. Managing these processes manually or with disconnected systems often leads to inefficiencies, data errors, and missed opportunities.

This is where our Dairy ERP system comes in. This system is tailored to the unique needs of dairy producers, processors, and distributors, integrating all core operations, including finance, inventory management, supply chain management, production management, and customer management. It streamlines operations and provides real-time insights to boost productivity and keep businesses competitive in a rapidly changing market.

In this blog, we’ll explore the key benefits of ERP software for dairy industry and why it has become an essential tool for modern dairy businesses.

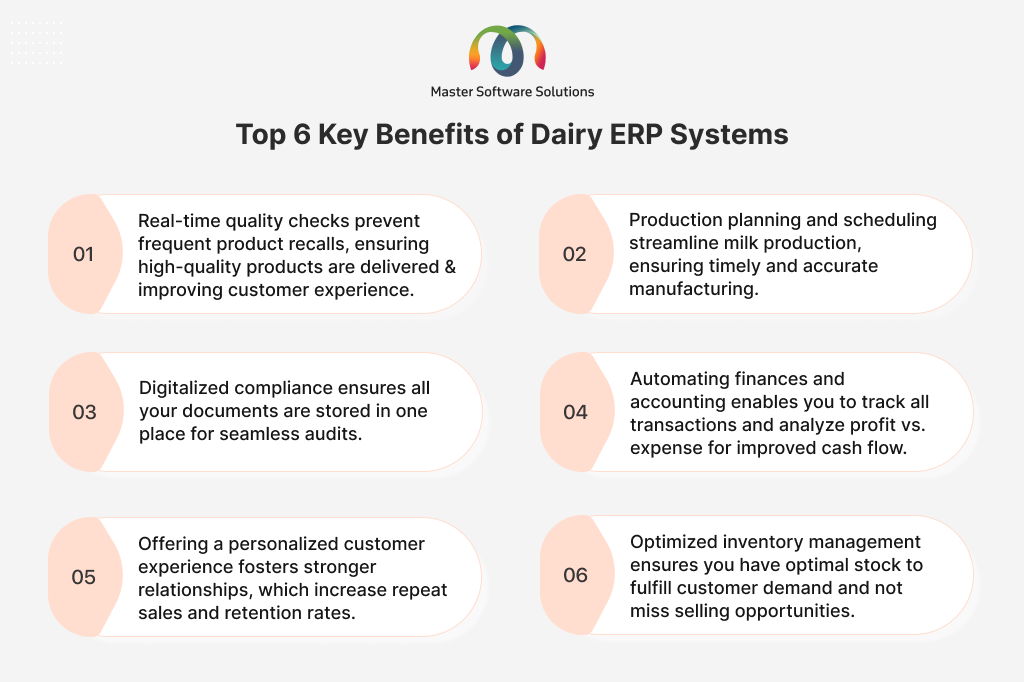

Top 6 key benefits of ERP systems

ERP systems provide advanced features and functionalities that help businesses optimize their processes, offering various benefits. The system unifies all the departments and their data on a single database, making it a “Single Source of Truth” and delivering multiple benefits. Here are notable benefits of ERP:

Real-time quality checks prevent frequent product recalls, ensuring high-quality products are delivered & improving customer experience.

In the dairy industry, quality and freshness are the foundation of customer trust. Since milk and dairy are highly perishable, even minor lapses in quality control can lead to contamination, spoilage, or product recalls, which not only increase costs but also damage brand reputation. Implementing an ERP system with real-time quality checks helps dairy businesses safeguard product quality at every stage of the supply chain. Working of quality checks in various dairy processing stages:

- Milk collection stage – As milk arrives from farmers or suppliers, ERP-integrated quality checks can record parameters like fat, temperature, SNF, and purity in real-time. Any deviation from standards is immediately flagged, preventing low-quality milk from entering the production process.

- Production stage – During processing, whether pasteurization, homogenization, or packaging, ERP systems automatically track compliance with safety standards (FSSAI, FDA, or HACCP). This reduces the risk of contaminants, incorrect formulations, or unsafe storage conditions.

- Storage & distribution – Real-time monitoring ensures that cold chain requirements are maintained throughout storage and transportation, reducing spoilage and ensuring that customers receive only fresh, high-quality products.

Benefits of real-time quality checks

- Fewer product recalls – Continuous quality monitoring minimizes the risk of defective or unsafe products reaching the market, significantly reducing recall costs and risks.

- Improved customer trust – Consistently delivering safe, fresh, and high-quality dairy products strengthens customer confidence and brand loyalty.

- Regulatory compliance – Real-time tracking enables you to meet safety standards and audit requirements, avoiding penalties or legal issues.

- Enhanced customer experience – Ensuring freshness and quality protects the dairy businesses’ reputation, improving customer satisfaction and repeat purchases.

The ERP system for the dairy industry enables businesses to produce safe, compliant, and high-quality products, thereby reducing risk and fostering customer trust in a competitive market.

Production planning and scheduling streamline milk production, ensuring timely and accurate manufacturing.

Production planning and scheduling play a vital role in ensuring milk and dairy products are processed, packaged, and delivered on time. With dairy products being highly perishable, even small delays or inefficiencies in production can lead to spoilage, missed delivery timelines, and customer dissatisfaction. An ERP system provides the tools to streamline and optimize these processes, ensuring accuracy, consistency, and profitability. Ways ERP helps in production planning and scheduling for dairy:

- Demand-driven production – ERP system utilizes sales history, customer orders, and seasonal trends to forecast demand. This ensures the right volume of milk, yogurt, butter, or cheese is produced, reducing the risk of overproduction and shortage.

- Milk collection and location management – The system integrates with collection centres to track incoming milk quantities and quality in real-time. This helps dairy businesses plan how much milk should be for pasteurization, cream separation, or cheese-making based on available stock.

- Automated scheduling – ERP creates optimized production schedules for processes such as pasteurization, homogenization, fermentation, and packaging. These schedules align with the available raw materials, workforce shifts, and machine capacity, ensuring efficient operations.

- Real-time adjustments – If there are fluctuations in milk supply or sudden spikes in demand, ERP enables businesses to instantly adjust production schedules without disrupting the entire operation.

- Efficient resource utilization – From manpower to cold storage to machinery, ERP ensures that resources are neither overused nor underutilized. This prevents bottlenecks, reduces downtime, and maximizes output efficiency.

- Regulatory compliance & traceability – ERP supports batch-wise scheduling, enabling businesses to maintain compliance with food safety regulations and ensuring full traceability from raw milk collection to final product delivery.

Benefits of production planning and scheduling of dairy ERP:

- Timely production – Products are manufactured and dispatched within required freshness timelines.

- Reduced wastage – Optimizing scheduling minimizes spoilage of raw milk and finished dairy goods.

- Improved customer satisfaction – Consistent supply ensures retailers and consumers get products on time.

- Lower operational costs – Efficient use of resources cuts unnecessary expenses.

- Enhanced profitability – Balanced production planning aligns supply with demand, boosting sales and margins.

Digitalized compliance ensures all your documents are stored in one place for seamless audits.

The dairy industry is heavily regulated, with strict requirements around food safety, quality standards, and traceability. Businesses must maintain detailed records for milk procurement and production processes, quality checks, storage, and distribution to ensure compliance with government and industry regulations. Managing these records manually through paper files or scattered spreadsheets not only increases the risk of errors but also makes audits time-consuming and stressful. The dairy ERP ensures that all the compliance-related documents are securely stored in a single, centralised platform. Ways ERP supports digitalized compliance in the dairy business are:

- Centralized document repository – All compliance documents, including licenses, certificates, supplier records, quality assurance reports, and audit trails, are stored in one secure digital system. This eliminates the hassle of managing multiple disconnected files or paper-based records.

- Automated record-keeping – ERP automatically captures and organizes production, procurement, and distribution data. For example, details of milk collection batches, pasteurization logs, quality test results, and cold chain monitoring data are recorded in real time, ensuring accuracy and transparency.

- Traceability for food safety – Dairy businesses must ensure end-to-end product traceability to meet food safety regulations. ERP links raw milk batches to production and distribution records, making it easy to trace any product back to its source for recalls or quality checks.

- Seamless audits – With all compliance documents available in one digital platform, audits become faster and stress-free. Auditors can easily access required records, reducing delays and avoiding penalties caused by missing or misplaced documents.

- Automated alerts and renewals – ERP systems can send automated alerts for license renewals, upcoming inspections, or quality compliance deadlines. This proactive approach ensures businesses never miss critical regulatory requirements.

- Reduced human errors – Since data is captured and stored automatically, the risk of manual entry errors in compliance reports is minimized, leading to greater accuracy and reliability in official submissions.

Benefits of digitizing compliance with an ERP system:

- Faster audit preparation – Reduced audit preparation time through centralized digital records that are easily accessible.

- Improved accuracy – Automated record-keeping and end-to-end traceability of milk batches and dairy products.

- Full regulatory visibility – Get complete visibility into regulatory deadlines with proactive alerts and notifications for renewals, inspections, and compliance tasks.

- Lower risks and penalties – Minimizes compliance risks and avoids penalties by eliminating errors, missing records, and missed deadlines.

- Stronger market credibility – Builds trust and transparency with regulators, partners, and customers through consistent compliance practices and reliable audit trails.

Automating finances and accounting enables you to track all transactions and analyze profit vs. expense for improved cash flow.

Managing finances in a dairy business is complex due to the involvement of multiple stakeholders and transactions, including milk procurement from farmers, payments to suppliers, operational expenses, sales to distributors and retailers, and customer collections. Handling these transactions manually through spreadsheets or disconnected tools is not only time-consuming but also prone to errors. This lack of accuracy often leads to financial discrepancies, poor visibility into cash flow, and delayed decision-making. A dairy ERP simplifies and strengthens financial management by automating accounting processes and providing real-time insights into profit, expense, and cash flow. Ways ERP automates finances and accounting in dairy businesses:

- Centralized transaction tracking – The ERP captures all financial transactions across procurement, production, sales, and distribution in a single, unified platform. This eliminates the silos of multiple systems, providing a single source of truth.

- Automated payables & receivables – The system streamlines Accounts Payable (AP) by tracking supplier invoices and payments, while Accounts Receivable (AR) ensures timely invoicing and collections from customers. This improves liquidity and reduces outstanding dues.

- Profit vs. expense analysis – ERP generates detailed reports comparing revenues against operational costs, including milk procurement, cold chain logistics, packaging, and labor. This helps identify profitable product lines and areas of cost leakage.

- Cash flow visibility – Real-time dashboards provide insights into inflows and outflows, enabling more suitable management of working capital and investment planning. Dairy businesses can forecast cash shortages or surpluses well in advance.

- Regulatory & tax compliance – Automated financial modules maintain accurate tax calculations, GST/VAT compliance, and statutory filings, reducing the risk of penalties or misreporting.

- Reduced errors & time savings – Eliminating manual bookkeeping and repetitive entries, ERP reduces human errors in invoices, reconciliations, and financial statements, saving valuable employee time.

Benefits of automating finance and accounting operations

- Faster closures – Reduce month-end and year-end financial closing through automation.

- Improved accuracy – Achieve accuracy in financial reporting with reduced manual intervention.

- Better cash flow management – Enhance visibility into working capital and ensure on-time collections, improving cash flow stability.

- Cost control & profitability – Identify cost leakages and track profitability across product categories, helping make smarter pricing and investment decisions.

- Regulatory confidence – Minimize penalties and ensure error-free tax compliance with automated financial reporting.

Offering a personalized customer experience fosters stronger relationships, which increase repeat sales and retention rates.

Customers, whether distributors, retailers, or end consumers, expect more than just timely deliveries. They value personalized experiences, including accurate order fulfillment, flexible subscription models, customized promotions, and responsive service. Managing this level of personalization manually is nearly impossible, especially when processing thousands of orders, different delivery schedules, and varying customer preferences.

ERP software for dairy businesses delivers a personalized, consistent, and customer-centric experience by centralizing customer data and automating engagement workflows. This improves satisfaction but also fosters loyalty, leading to higher repeat sales and long-term retention. Ways ERP software enables personalized customer experience in the dairy business:

- 360-degree customer view – ERP consolidates all customer-related information, including order history, payment records, delivery preferences, and communication logs into a single platform. This allows businesses to understand customer needs and buying patterns.

- Personalized order management – Customers can set preferences for product types (milk, yogurt, & butter), quantities, and delivery schedules. ERP ensures these preferences are automatically applied to recurring orders, avoiding errors and improving convenience.

- Custom pricing & discounts – ERP can manage customer-specific pricing, loyalty discounts, or promotional offers, making customers feel valued while encouraging repeat purchases.

- Efficient subscription and delivery management – For dairy subscription models (daily, alternate, or custom day milk delivery), ERP automates scheduling, invoicing, and adjustments (e.g., pausing or resuming subscriptions and modifying orders), ensuring a smooth and personalized experience.

- Quick and responsive support – Integration with customer support modules enables teams to address complaints or inquiries faster, backed by accurate customer data. This responsiveness enhances trust and long-term relationships.

- Data-driven insights for personalization – ERP analyzes purchase history and customer behavior to help businesses design personalized campaigns, recommend products, or introduce seasonal offers.

Benefits of offering a personalized customer experience with dairy ERP

- Higher repeat sales – Personalized service increases repeat purchases and boosts customer lifetime value (CLV).

- Stronger retention rates – Improve customer retention rates through tailored engagement and consistent service.

- Better order accuracy – Automated ordering processes reduce order errors, resulting in increased customer satisfaction.

- Increased revenue – Personalized upselling and cross-selling opportunities can help boost revenue growth.

- Enhanced brand loyalty – A consistent customer-first approach strengthens brand credibility and fosters long-term loyalty.

Optimized inventory management ensures you have optimal stock to fulfill customer demand and not miss selling opportunities.

Inventory management is a critical function in a dairy business because products like milk, curd, butter, and cheese are highly perishable. Overstocking can quickly lead to wastage, while understocking causes stockouts, lost sales, and unhappy customers. Many dairy businesses relying on manual tracking or disconnected systems struggle to balance supply and demand effectively.

An ERP provides real-time visibility, automation, and demand-driven insights that help businesses maintain accurate stock levels, minimize waste, and fulfill customer orders on time, ensuring optimized inventory management. Ways ERP optimizes inventory management in the dairy business:

- Real-time stock visibility – ERP provides complete visibility of raw materials, semi-processed goods, and finished dairy products across multiple facilities, including collecting centres, production units, and cold storage facilities.

- Demand forecasting & stock planning – Analyzing sales history, seasonal trends, and customer orders, ERP forecasts demand and suggests optimal stock levels, ensuring businesses don’t under- or over-produce.

- Expiry & shelf life tracking – ERP tracks product batches with expiry dates, ensuring first-expiry-first-out (FEFO) or first-in-first-out (FIFO) inventory management. This minimizes spoilage and maximizes production utilization.

- Automated replenishment – The system sets reorder points and generates purchase orders when stock drops below thresholds, preventing last-minute shortages of raw materials or packaging supplies.

- Integrated cold chain monitoring – ERP links with logistics and storage to ensure cold chain integrity, maintaining product quality during storage and delivery.

- Reduced inventory carrying costs – Optimizing stock levels, businesses avoid overstocking that ties up capital and increases storage expenses.

Benefits of optimizing inventory management with dairy ERP

- Better demand fulfillment – Ensuring optimal stock levels by aligning inventory with actual customer demand improves order fulfillment rates.

- Reduced wastage – Lower dairy product spoilage through shelf life tracking and optimized stock rotation.

- Lower inventory costs – Cut excess stock and reduce carrying costs with accurate inventory reporting.

- Faster turnover – Improve inventory turnover by ensuring fast product movement through FEFO/FIFO methods.

- Higher customer satisfaction – Consistently meeting customer demands without delays boosts repeat orders and customer loyalty.

Next-Step

Dairy businesses thrive on precision, speed, and consistency, and an ERP for dairy manufacturers empowers them to achieve exactly that. Centralizing operations enhances traceability, ensures compliance, and optimize every stage from milk collection to distribution, eliminating inefficiencies. Investing in Dairy ERP implementation offers you real-time control over your business while improving profitability and customer satisfaction.