Role of Artificial Intelligence (AI) in the Bottled Water Industry

The bottled water industry is driven by growing demand for healthy and pure water, increasing competition, and the rising need for operational efficiency. The global bottled water market size was estimated at USD 348.64 billion in 2024 and is projected to reach USD 509.18 billion by 2030, growing at a CAGR of 6.4% from 2025 to 2030. In such a rapidly evolving bottled water industry, Artificial Intelligence is transforming the way you source (water), process, pack, distribute, and sell it.

From predicting demand patterns and optimizing delivery routes to ensuring quality compliance and automating customer interaction, AI is making businesses smarter, faster, and more customer-centric. AI integrations can help you enhance the functionality of your enterprise resource planning (ERP) system.

This Use Case explores the role of AI in the bottled water industry and how businesses can help you gain a competitive advantage.

This Use Case Covers

Understanding the role of AI in the bottled water industry

Artificial Intelligence (AI) is transforming the bottled water industry at every operational stage, streamlining processes and improving product quality and customer experience. In production, AI-powered systems enable real-time product quality control, predictive maintenance of machinery, and process optimization. For logistics, AI helps optimize delivery routes, reduce fuel costs, and improve fleet management.

On the inventory side, AI-driven demand forecasting prevents stockouts and overstocking. In sales and customer service, AI chatbots, personalized marketing, and churn prediction tools boost engagement and retention. AI also contributes to sustainability by monitoring water usage and optimizing energy consumption. Overall, AI enables bottled water businesses to operate more efficiently, deliver faster, and adapt smartly to market trends.

Challenges in the bottled water industry with AI

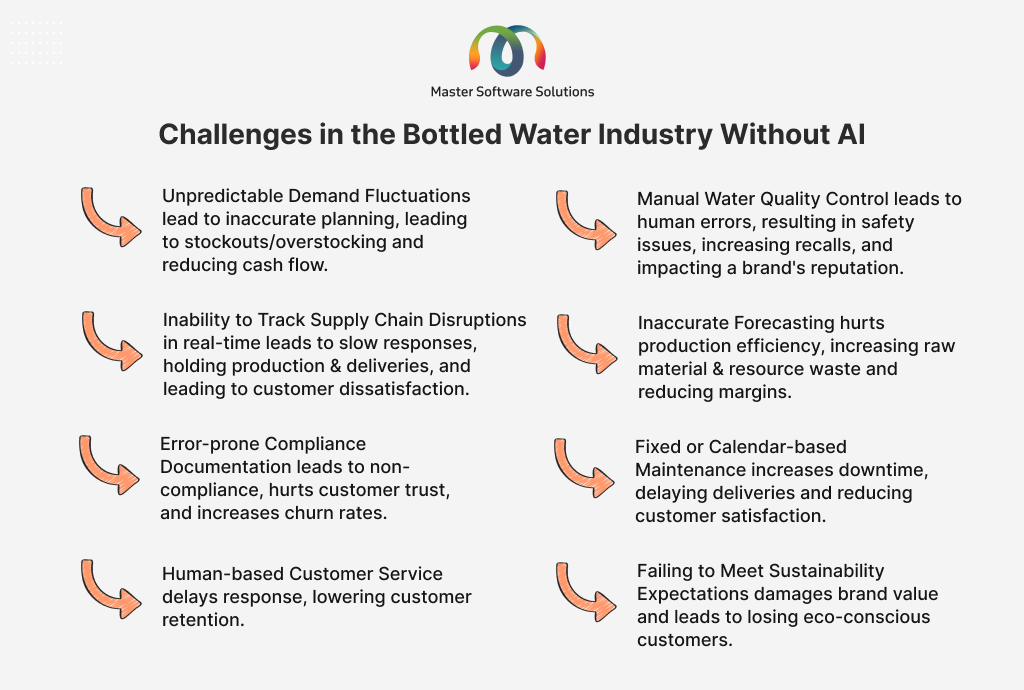

As bottled water businesses scale to meet growing consumer demand, they face complex operational and quality challenges across their supply chain. From unstable demand patterns to supply chain disruptions, these challenges can significantly impact customer satisfaction, operational efficiency, and profitability. Understanding these pain points is essential for businesses looking to implement AI as a strategic tool to improve their operational efficiency. Here are the challenges faced by bottled water businesses without AI:

Unpredictable demand fluctuations lead to inaccurate planning, leading to stockouts/overstocking and reducing cash flow.

You can’t accurately track or forecast unpredictable demand fluctuations, which leads to overstocking or understocking. Overstocking water bottles takes up storage space and ties up capital. On the other hand, understocking can lead to stockouts, resulting in missed sales opportunities. This inconsistency in stocks creates an unreliable supply chain, affecting customer trust and working capital, which can negatively impact cash flow and profitability.

Manual water quality control leads to human errors, resulting in safety issues, increasing recalls, and impacting a brand’s reputation.

Inconsistent quality control can lead to health risks, product recalls, or bad customer reviews. Without an AI-powered real-time monitoring or predictive analytics, identifying issues early becomes difficult. This can damage your brand’s image and erode customer trust, potentially leading to regulatory fines or a loss of market share.

Inability to track supply chain disruptions in real-time leads to slow responses, holding production & deliveries, and leading to customer dissatisfaction.

Without end-to-end visibility, you can’t quickly detect disruption or delays in sourcing, manufacturing, or logistics. This leads to misalignment between production schedules and deliveries, resulting in late shipments and customer dissatisfaction. It also hinders proactive decision-making and risk management.

Inaccurate forecasting hurts production efficiency, increasing raw material & resource waste and reducing margins.

Manual or outdated forecasting methods often result in production that doesn’t match the real demand. This leads to excess production, raw material wastage, and inefficient use of labor and energy. It also increases holding costs and lowers operational efficiency, directly impacting margins.

Error-prone compliance documentation leads to non-compliance, hurts customer trust, and increases churn rates.

Manual compliance processes are slow and prone to human errors. Missed documentation or inaccurate reports can lead to regulatory non-compliance, fines, and damaged credibility. For customers, this determines trust, especially in bottled water businesses where quality and safety standards are critical.

Fixed or calendar-based maintenance increases downtime, delaying deliveries and reducing customer satisfaction.

Fixed or calendar-based maintenance doesn’t consider real-time usage or wear. Waiting for equipment to fail before servicing (reactive maintenance) leads to longer downtimes, costly emergency repairs, and missed delivery deadlines. This disrupts production flow and creates a domino effect across the supply chain, impacting customer satisfaction and brand reliability.

Lack of automated customer service delays response, lowering customer retention.

Manual customer service channels (calls or emails) are slow and often unavailable 24/7. Delayed responses to order inquiries, complaints, or delivery issues frustrate customers. With AI-based chatbots or automated systems, retaining customers becomes difficult in a competitive market.

Failing to meet sustainability expectations damages brand value and leads to losing eco-conscious customers.

Consumers increasingly expect eco-friendly packaging, sustainable sourcing, and carbon-conscious operations. The bottled water businesses fail to track and report their sustainability performance or reduce their environmental footprint, risking losing environmentally conscious customers and investor confidence.

Ways AI can improve your bottled water operations

The bottled water industry operates in a fast-moving, demand-sensitive environment where efficiency, quality, and customer satisfaction are critical to success. As consumer expectations rise and operational complexities grow, artificial intelligence is bringing a paradigm change. Here are the ways AI can improve your bottled water operations:

Accurate AI forecasting ensures optimal stock, improves cash flow, and ensures timely deliveries.

AI uses historical sales data, weather patterns, customer buying behavior, and seasonal trends to predict demand with precision. This helps maintain the right inventory levels, avoiding stocking or stockouts, which results in better cash flow, reduced waste, and smoother on-time deliveries.

Real-time QC monitoring ensures safety, boosts compliance, & protects brand reputation, improving customer satisfaction.

AI-driven sensors and machine learning models monitor water quality parameters (pH, TDS, and turbidity) in real-time. Any deviation from safety parameters can trigger alerts instantly. This proactive quality assurance reduces health risks, ensures regulatory compliance, and builds a reputation for consistently safe products.

Live supply chain visibility allows faster decisions, keeping production & deliveries on track for reliable deliveries.

AI tools provide a real-time view of the entire supply chain, including raw material arrival, production flow, fleet movement, and delivery routes. When issues arise (delays or inventory shortages), AI alerts managers to take quick corrective actions, keeping everything running smoothly and minimizing disruption.

Accurate, real-time production forecasting reduces raw material and resource waste, minimizing expense and maximizing profits.

AI can analyze order patterns, machine capacity, and workforce availability to forecast production needs. This leads to smarter batch planning and avoids overproduction, reducing wastage of water, bottles, labels, energy, and labor, ultimately cutting operational costs.

AI-powered compliance tracking minimizes errors, improving compliance and customer trust.

AI-powered systems automate documentation for safety, hygiene, and industry standards. They can flag missing or inaccurate entries, generate reports instantly, and ensure timely submission to authorities. This reduces regulatory risks and reassures customers that the brand meets safety and quality benchmarks.

AI-predictive equipment care reduces delays, improving timely and reliable deliveries and enhancing customer satisfaction.

AI uses machine learning and IoT sensors to predict when a machine is likely to fail based on its usage patterns and conditions. This enables you to schedule maintenance before breakdown occurs, reducing unplanned downtime and ensuring consistent production and delivery schedules.

Customer support delivers instant & personalized responses, increasing retention rates.

AI chatbots and virtual assistants provide 24/7 customer support, answering questions, resolving complaints, and handling order tracking in real-time. They can also personalize interactions using customer data, improving satisfaction and increasing customer loyalty in a competitive market.

Real-time sustainability KPI tracking identifies inefficiencies, boosting brand reputation and customer experience.

AI can track environmental KPIs such as usage per unit, plastic waste, energy consumption, and carbon emissions. Analyzing this data can help businesses to identify improvement areas, optimize sustainability efforts, and transparently report progress, strengthening their image to eco-conscious consumers and stakeholders.

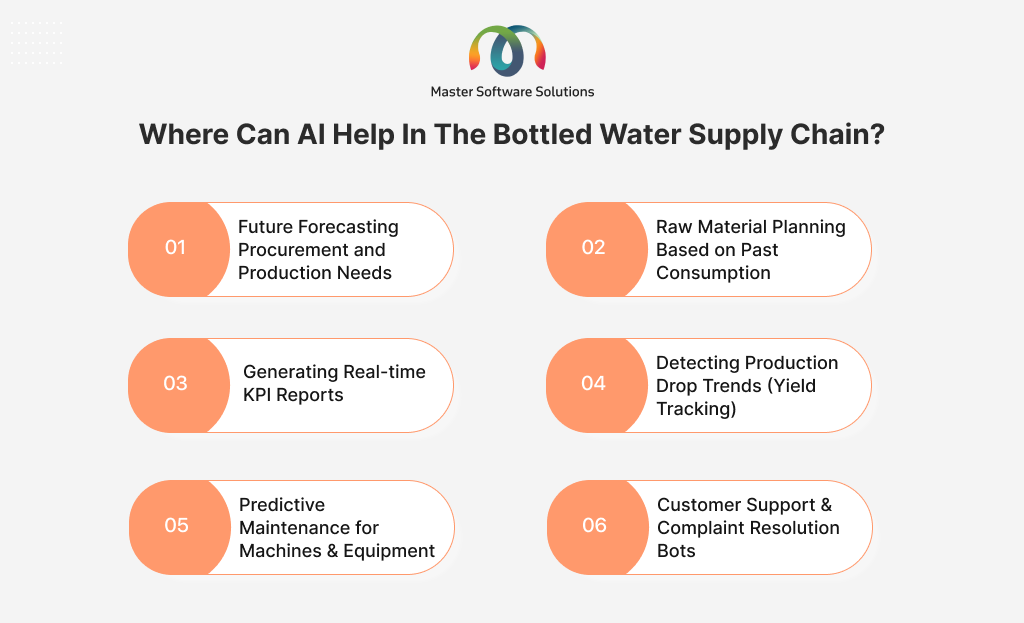

Where can AI help in the bottled water supply chain?

Managing the bottled water supply chain requires precision, speed, and adaptability, from sourcing raw materials to delivering the final product. However, traditional supply chain processes fall short in handling dynamic demand, quality assurance, and real-time decision-making. Integrating AI into various stages of the supply chain can help you forecast future demand accurately, plan resources, ensure product quality, and respond faster to disruptions. Supply chain aspects where AI can help streamline your bottled water business

Future forecasting procurement and production needs

AI analyzes historical data (sales, weather patterns, customer demand, seasonality) and external variables (holidays, promotions, and market trends) to accurately forecast future demand. This ensures the timely procurement of bottles, caps, water, and other materials, balanced production planning to reduce overproduction or stockouts, and improved work capital usage by avoiding unnecessary inventory buildup.

Raw material planning based on past consumption

AI can track historical raw material usage patterns and align them with forecasted demand to predict exactly how much of each input is required. This helps minimize material wastage, avoids emergency purchases due to understocking, and streamlines supplier coordination and procurement scheduling.

Generating real-time KPI reports

AI can collect data from various touchpoints, including production lines, delivery lines, delivery systems, inventory levels, and customer feedback to automatically generate real-time, visual KPI dashboards. These dashboards show bottling efficiency, order fulfillment rates, delivery timelines, and machine uptime vs. downtime, enabling faster, data-driven decisions to optimize operations.

Detecting Production drop trends (yield tracking)

AI continuously monitors production output and detects subtle shifts or declines in yield that a human operator might miss. It can identify root causes such as machine performance degradation, operator errors, and batch inconsistencies. The AI can spot early warning signs and help improve consistency and avoid larger-scale production issues.

Predictive maintenance for machines & equipment

AI-powered predictive maintenance uses sensors and machine learning to monitor vibrations, temperatures, cycles, and wear patterns. It can predict when machines are likely to fail and when a component needs replacement. This allows scheduling maintenance before breakdowns occur, reducing costly downtime and keeping production schedules intact.

Customer support & complaint resolution bots

AI chatbots and virtual agents automate customer interactions across web, app, and messaging channels. They can answer FAQs (delivery timelines, pricing, order status), handle complaints or issues, and route complex issues to human agents when needed. This ensures 24/7 support, faster response times, and a better customer experience, boosting satisfaction and retention rates.

Types of AI agents used in the dairy industry

Predictive demand forecasting agents

It utilizes AI/ML to analyze historical data, seasonality, weather, and market trends. It ensures optimized inventory levels and minimizes last-minute production changes, preventing stockouts/overstocking, improving cash flow, and providing timely fulfillment.

Replenishment AI agents

These AI agents monitor real-time inventory levels and trigger automated replenishment requests. They help you maintain healthy stock levels without manual tracking, reducing manual efforts, avoiding emergency purchases, and lowering carrying costs.

Production schedule optimizing agents.

The production schedule optimizing agents adjust production schedules dynamically based on demand, raw material availability, and equipment capacity. This helps improve machine utilization and avoids bottlenecks, enhancing production efficiency, reducing energy and labor costs, and improving on-time order completion.

Bill of Material AI agents

The agents automate and optimize BoM creation and revision using historical production data, supplier inputs, and process efficiencies. This ensures accurate material listings and quantities, adjusts BoM dynamically based on production variations or packaging updates, and prevents overuse or storage of raw material. These agents can help you reduce material wastage and production errors, accelerate product development and cost estimation, and ensure cost-efficient and consistent production.

Real-time quality monitoring agents

These agents look for variations in water quality by gathering and evaluating real-time data from sensors (temperature, turbidity, and pH). It enables instant correction before contaminated batches are released. This safeguards the brand’s reputation while guaranteeing water safety and regulatory compliance.

Quality compliance tracking agents

The quality compliance tracking agents monitor real-time data from sensors and lab results, track documentation, and flag deviations from water safety and packaging standards. They ensure continuous alignment with regulatory standards (FSSAI, ISO, and BIS), prevent non-compliant batches from reaching the market, and simplify audit readiness and certification. This reduces compliance risk and penalty exposure, builds customer trust and brand reputation, and enhances internal quality processes and accountability.

Supplier risk analysis agents

These artificial intelligence (AI) agents assess vendor dependability using information like market alerts, rejection rates, and delivery delays. They identify supplier-related risks before they influence operations. This strengthens supplier relationships, avoids disruptions, and ensures consistent supply.

Smart purchase advising agents

The agents analyze price trends, supplier performance, lead times, stock levels, and demand forecasts to recommend the best quantity and vendor for procurement. These agents reduce over-purchasing and urgent procurement costs, improve selection and negotiation terms, and ensure material availability without tying up capital. This reduces purchasing costs, strengthens supplier-vendor relationships, and enables a just-in-time inventory strategy.

Warehouse slotting optimizing agents.

These agents utilize artificial intelligence technologies to determine the best placement of products in the warehouse based on their movement frequency, weight, dimensions, and order patterns. This minimizes travel time for pickers, avoids congestion and misplacement, and balances the load across the warehouse zone, increasing picking and packing speed. They also help enhance warehouse efficiency and throughput, reduce labor costs, and minimize fulfillment errors.

Inventory health monitoring agents

Inventory health monitoring agents monitor inventory in real-time to detect slow-moving, deadstock, expired, or damaged goods and suggest redistribution, clearance, or reordering actions. They help prevent capital from being locked in unsellable stock, reduce wastage from expired products, especially in multi-pack bottles or flavored variants, and maintain a balanced and healthy inventory. This improves the inventory turnover ratio, saves storage space and carrying costs, and enhances responsiveness to market demand.

Product recommendation agents

Suggest personalized product quantities or subscription plans to your customers based on their past orders and consumption trends. It improves upselling, cross-selling, and customer satisfaction. This can be extremely beneficial to businesses that sell bottled water alongside other products, such as coffee or rentals.

AI customer assistant agents

They are AI-powered chatbots that respond instantly to customer queries, complaints, and order status inquiries, reducing manual support load and improving response times. Implementing such AI agents with your CRM can help you boost customer satisfaction and loyalty.

Pricing intelligent agents

These AI agents analyze real-time competitor pricing, customer behavior, demand trends, stock levels, and market dynamics to recommend optimal pricing strategies. They enable dynamic pricing (seasonal surges and discounts for slow-moving stock), prevent revenue loss due to underpricing or overpricing, and help align price with demand and profitability. The pricing intelligent agents boost profit margins, enhance market competitiveness, and support personalized pricing for high-value customers or bulk orders.

Social sentiment monitoring agents

These agents scan and analyze your customer reviews, social media mentions, forums, and feedback about your brand, products, and services. They help identify reputation risks or rising customer concerns early, detect product issues, service delays, or trending preferences, and enable proactive brand engagement. This strengthens brand loyalty and consumer trust, informs product improvement and marketing strategies, and enhances public relations and crisis planning.

Route optimization agents

It determines the fastest and most fuel-efficient delivery routes based on real-time weather, traffic, and delivery priority data. This can help you reduce fuel costs, delivery times, and carbon footprint.

Delivery prediction tracking agents

These agents predict potential delays or exceptions and update delivery ETAs in real time, increasing transparency. Providing customers with the estimated arrival time of their order enhances customer communication and trust.

Predictive maintenance bot

The agents analyze machine data (vibrations, heat, cycles) to detect early signs of wear, scheduling maintenance before breakdowns. This reduces downtime, lowers maintenance costs, and increases equipment lifespan.

Compliance documentation agents

The compliance documentation agents generate and verify reports based on changing regulatory standards, keeping compliance up to date. This reduces audit preparation time and ensures regulatory alignment.

Fraud and anomaly detector

The agent detects irregular transactions and patterns in billing, procurement, or payroll, preventing internal and vendor fraud. The fraud and anomaly detector improves financial integrity and reduces losses.

Real-time sustainability tracking agents

The AI agents monitor water usage, plastic consumption, emissions, and energy usage to identify sustainability gaps in operations. This enhances ESG (Environmental, Social, and Governance), reduces environmental impact, and helps build an eco-conscious brand identity.

Waste reduction agents

Identifies trends in material waste (bottles, packaging, water loss) and makes recommendations for process enhancements that will improve yield management, lower operating costs, and promote environmentally friendly behaviours.

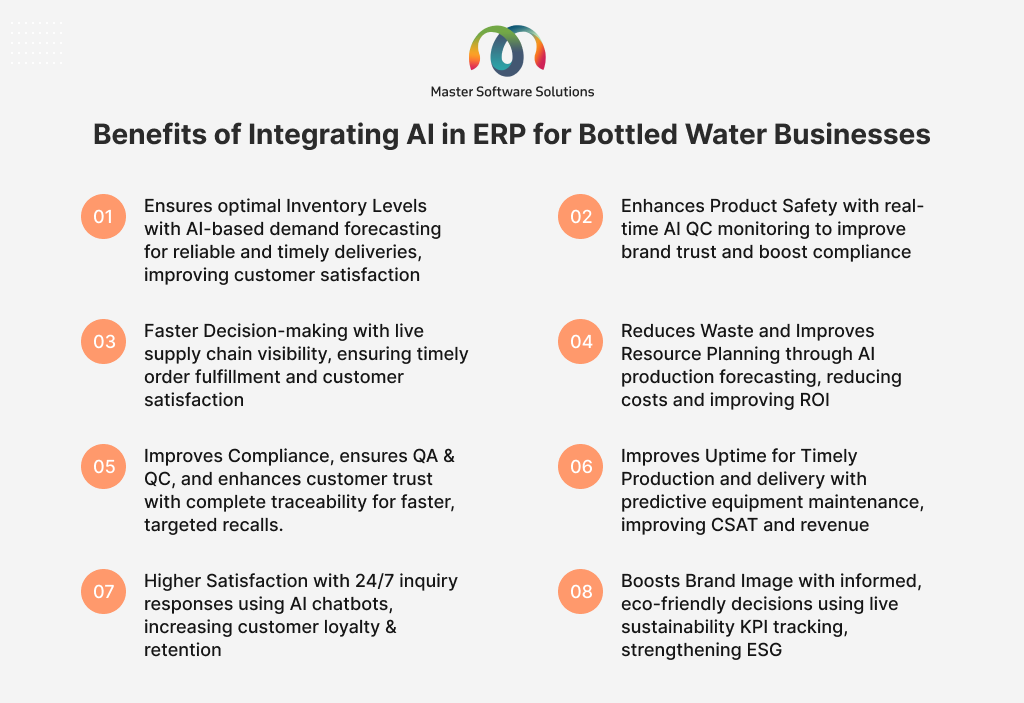

Benefits of integrating AI in your ERP for bottled water businesses

While ERP helps businesses centralize and automate core business processes, integrating artificial intelligence takes this a step further, adding smartness, adaptability, and real-time decision-making. AI-enhanced ERP systems enable businesses to forecast accurate demand, manage inventory proactively, maintain product quality, and optimize supply chain performance. Here are the benefits of integrating AI into your bottled water ERP:

Ensures optimal inventory levels with AI-based demand forecasting for reliable and timely deliveries, improving customer satisfaction.

AI integrated in the bottled water ERP continuously analyzes historical sales, seasonal patterns, location-wise consumption, and even external data (water, events) to predict future demand. This allows ERP to suggest optimal stock levels at the right place, ensuring timely order fulfillment without overstocking. This reduces stockouts and overstock, smoothens deliveries, and ensures better cash flow and happier customers.

Enhances product safety with real-time AI QC monitoring to improve brand trust and boost compliance

AI sensors within the production line feed real-time data (pH levels, turbidity, minerals) into the ERP. Machine learning models detect anomalies instantly and trigger alerts or halt production if safety limits are breached. This helps you detect quality issues early, ensure consistent product safety, and boost regulatory compliance and brand trust.

Faster decision-making with live supply chain visibility, ensuring timely order fulfillment and customer satisfaction.

AI enables real-time monitoring of every aspect of the supply chain, including raw material inflow, production status, vehicle location, and delivery progress. The ERP uses this data to identify disruptions (supplier delays, route congestion) and suggest immediate corrective actions. This reduces delays in response, minimizes production stoppages, and ensures a resilient and agile supply chain, reducing operational costs, improving on-time delivery rates, and enhancing customer satisfaction.

Reduces waste and improves resource planning through AI production forecasting, reducing costs and improving ROI.

AI forecasts production needs based on sales trends, seasonality, and capacity. It adjusts production plans dynamically, ensuring you don’t overproduce or underutilize resources. Integration with ERP allows these forecasts to automatically drive material requisition (a formal process of requesting the raw materials or components needed for production) and labor planning.

Improves compliance, ensures QA & QC, and enhances customer trust with complete traceability for faster, targeted recalls.

AI in ERP systems tracks every batch of water source, purification steps, packaging, and distribution. In case of issues, it can trace affected units in seconds. It also automates regulatory reporting and flags non-compliance risks early. This leads to faster recalls, full audit trails for regulators, and fosters customer and stakeholder trust. This improves the brand’s reliability and prevents legal penalties.

Improves uptime for timely production and delivery with predictive equipment maintenance, improving CSAT and revenue.

Sensors on equipment send performance data to AI models that predict wear, faults, or potential breakdowns. The ERP uses this to schedule maintenance before failure, reducing unplanned downtime. This leads to a higher machine uptime, on-schedule production and deliveries, and lowers repair costs, ensuring timely deliveries, enhancing customer satisfaction rates (CSAT), and increasing revenue.

Higher satisfaction with 24/7 inquiry responses using AI chatbots, increasing customer loyalty & retention.

AI-powered chatbots integrated with the ERP can access order data, delivery status, complaint logs, and FAQs to respond instantly to customer enquiries via web, mobile, or messaging apps without human intervention. This results in faster resolution of customer issues, 24/7 support availability, and increased customer loyalty and retention.

Boosts brand image with informed, eco-friendly decisions using live sustainability KPI tracking, strengthening ESG.

AI can track key sustainability metrics, including water consumption, energy usage, plastic usage, and CO₂ emissions, and flag inefficiencies. These KPIs are updated in real-time in your ERP dashboard, helping businesses make informed decisions to reduce environmental impact. This lowers environmental footprint, strengthens ESG (Environmental, Social, and Governance) compliance, and enhances appeal to eco-conscious customers and investors.

Conclusion

Integrating artificial intelligence in the bottled water supply chain has become essential to stand out in this highly competitive marketplace. AI capabilities to forecast demand accurately, optimize the bottling process, and enhance customer service have transformed how bottled water businesses operate their processes, make decisions, and adapt to a dynamically changing market landscape.

Master Software Solutions provides one-stop services to the bottled water businesses, including ERP consulting services and AI business process & consultation services. Our AI services include AI agent development, AI chatbot development, robotic process automation consultation, workflow automation services, and business process automation services. Let us help you automate your bottled water business processes to improve efficiency and productivity and boost ROI. Schedule a call to discuss your business workflow.