How is AI in the Coffee Industry Transforming Businesses?

The coffee industry is undergoing a technological transformation, from beans to brew, and Artificial Intelligence (AI) is the core of it. Rising demand for quality, consistency, and sustainability: coffee producers, distributors, and retailers are adopting AI to gain a competitive edge. Whether you are looking to optimize roasting profiles, automate quality checks, or personalize customer experience, AI is helping businesses make smarter, faster, and more profitable decisions.

The global coffee market size was estimated at USD 269.27 billion in 2024 and is projected to reach USD 369.46 billion by 2030, growing at a CAGR of 5.3% from 2025 to 2030. The overall demand for coffee is a significant driver of the market. With such increasing coffee demand, businesses are adopting the latest technologies, such as artificial intelligence, machine learning, and ERP solutions, to improve their overall yield while ensuring consistent product quality.

This blog explores how AI is not only streamlining the coffee supply chain but also creating new opportunities for growth and sustainability.

This blog covers:

Understanding the role of AI in the coffee industry

Coffee is one of the most popular drinks worldwide. According to Grand View Research, a report published by the National Coffee Association (NCA) highlighted that coffee was the most consumed beverage in the U.S. after water. It recorded that the daily consumption of coffee among adults was 67%, which was 49% higher than in 2004. Consistent consumer demand and evolving preferences are driving the market growth of the coffee industry.

The coffee industry has relied on traditional methods for many years; however, modern challenges, such as changing weather, rising costs, and increasing customer demands, necessitate smarter solutions. This is where Artificial Intelligence (AI) comes in, helping coffee businesses manage supply chains, maintain quality checks, and connect with customers, making every step efficient, reliable, and personalized. Understanding how AI works in the coffee industry, you’ll learn how it is helping businesses grow, adapt, and stay ahead.

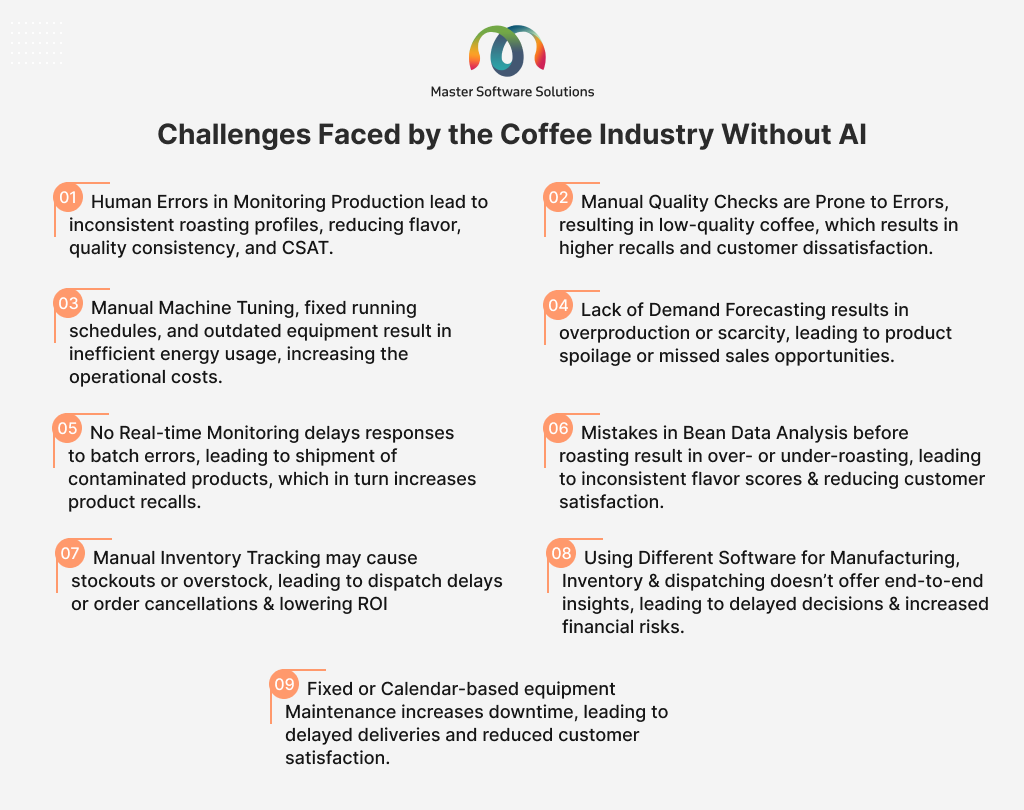

Challenges faced by the coffee industry without AI

In the coffee industry, efficiency, quality, and consistency are critical for increasing consumer loyalty and brand reputation. Many roasters and producers struggle to maintain these standards. Manual processes, fragmented systems, and the absence of real-time insights create disruptions that affect every stage, from sourcing to packaging and delivery. This leads to higher operational costs, increased waste, and dissatisfied customers. Here are the key challenges the coffee industry faces without an AI implementation:

Human errors in monitoring production lead to inconsistent roasting profiles, reducing flavor, quality consistency, and CSAT.

Without AI-driven sensors and automation, roasting relies on manual monitoring. Even a slight misjudgement in time, temperature, or bean conditions can alter the roasting profile. This inconsistency causes coffee to taste different from batch to batch, reducing brand trust and lowering customer satisfaction scores (CSAT).

Manual quality checks are prone to errors, resulting in low-quality coffee, which results in higher recalls and customer dissatisfaction.

Human inspections, such as visual colour checks or taste testing, are used to control quality, but they can overlook minor flaws. This increases the odds of defective batches reaching customers, resulting in product returns, costly recalls, and a damaged reputation.

Manual machine tuning, fixed running schedules, and outdated equipment result in inefficient energy usage, increasing the operational costs.

Without AI optimizations, equipment often operates on static schedules instead of adjusting based on demand or production load. This means machines may run idle, use excess energy, or operate under suboptimal conditions, wasting resources and inflating utility bills.

The lack of demand forecasting results in overproduction or scarcity, leading to product spoilage or missed sales opportunities.

Relying on gut feelings or historical averages instead of AI forecasting can cause mismatched production. Overproduction leads to stale or expired coffee stock, while underproduction results in stockouts, lost customers, and revenue loss.

No real-time monitoring delays responses to batch errors, leading to shipment of contaminated products, which in turn increases product recalls.

If there is no automated, real-time batch monitoring, problems such as contamination or off-flavor can go unnoticed until after shipment of the coffee. This can trigger large-scale product recalls, increase compliance risks, and harm customer trust.

Mistakes in bean data analysis before roasting result in over- or under-roasting, leading to inconsistent flavor scores & reducing customer satisfaction.

Each batch of beans has unique moisture, density, and origin attributes. Without AI analysis, misinterpretation of these variables can result in incorrect roast levels and low-quality coffee that fails to meet flavour or quality standards.

Manual inventory tracking may cause stockouts or overstock, leading to dispatch delays or order cancellations & lowering ROI

Human-led stock tracking is prone to errors and delays in updates. This can create situations where you run out of key raw materials or over-purchase items that expire before use, both of which reduce return on investment (ROI).

Using different software for Manufacturing, Inventory & dispatching doesn’t offer end-to-end insights, leading to delayed decisions & increased financial risks.

Siloed systems mean data isn’t integrated. Decision-makers can’t see a unified, real-time picture of production, stock, and delivery. This lack of visibility delays corrective actions increases operational inefficiencies, and exposes the business to financial losses.

Fixed or calendar-based equipment maintenance increases downtime, leading to delayed deliveries and reduced customer satisfaction.

Without AI-based predictive maintenance, machines are serviced on fixed schedules rather than when they need it. This may cause unnecessary downtime or unexpected breakdowns, both of which slow production and delay deliveries.

Ways AI is transforming the coffee industry

Coffee production is a delicate process, from bean selection to final packaging. Even small inconsistencies in the operations can affect flavor, quality, and customer satisfaction. Artificial Intelligence (AI) is reshaping the coffee industry, bringing precision, speed, and real-time insights into every stage of the coffee journey. Automating repetitive tasks, predicting market demand, and analyzing data from bean quality to sales performance, AI empowers coffee businesses to produce consistently high-quality products, reduce waste, optimize resources, and boost profitability. Here are the ways AI is revolutionizing coffee production and operations.

AI analyzes bean data to adjust roasting settings, ensuring consistent flavour and quality, and improving customer trust.

AI systems assess critical bean characteristics, like moisture content, size, and origin profile, before roasting. Using this data, AI can automatically fine-tune time, temperature, and airflow settings, ensuring that each batch achieves a consistent flavor profile, boosting brand consistency and customer confidence.

AI-powered sensors track quality during roasting, detecting flaws instantly and reducing recalls & financial losses.

During roasting, AI-enabled sensors monitor color, aroma, and temperature in real-time. If anomalies like uneven roasting or scorching occur, the system alerts the operator or adjusts parameters instantly. This prevents defective batches from being packaged, minimizing the need for costly recalls and protecting the brand’s reputation.

AI-powered predictive equipment care reduces delays, improving timely deliveries and increasing customer satisfaction.

Continuous equipment performance data analysis enables AI to predict when parts are likely to fail or require maintenance. This allows proactive maintenance scheduling, preventing unexpected breakdowns that cause production delays and missed delivery deadlines.

AI-powered demand forecasts avoid overstocking or shortages, ensuring timely deliveries and improving ROI.

AI utilizes historical trends, promotions, and external data (like weather or market conditions) to predict demand with high accuracy. This helps producers make precise roasting schedules, preventing inventory pile-ups or stockouts, reducing waste, and maximizing return on investment.

Computer vision and AI detect and remove defective beans before roasting, reducing waste & improving coffee quality.

High-resolution cameras and AI algorithms scan beans for things such as cracks, discoloration, or insect damage. The defective beans are automatically removed, ensuring that only high-quality raw materials enter the roaster, resulting in a better final product and less waste.

Automate roasting repetitive steps, from bean input to cooling & packaging, freeing your staff and improving consistency.

AI-driven automation can control repetitive production steps, including loading beans, managing roasting cycles, cooling, and packaging, with constant human intervention. This reduces labor strain, speeds up processing, and maintains consistency across batches.

AI centralizes the business data to generate actionable insights on KPIs, helping you make informed decisions, improve coffee yield & minimize revenue leakage.

Instead of relying on scattered reports, AI integrates data from roasting, inventory sales, and delivery systems into a unified dashboard. This enables decision-makers to track KPIs in real-time, identify inefficiencies, and quickly improve yield and reduce losses.

AI analyzes business data (such as sales, procurement, or roasting) and offers recommendations to maximize yield & reduce revenue loss.

Beyond monitoring, AI identifies patterns and offers actionable recommendations, including optimal roast schedules, supplier negotiations, or sales strategies, helping businesses run leaner operations and protect profit margins.

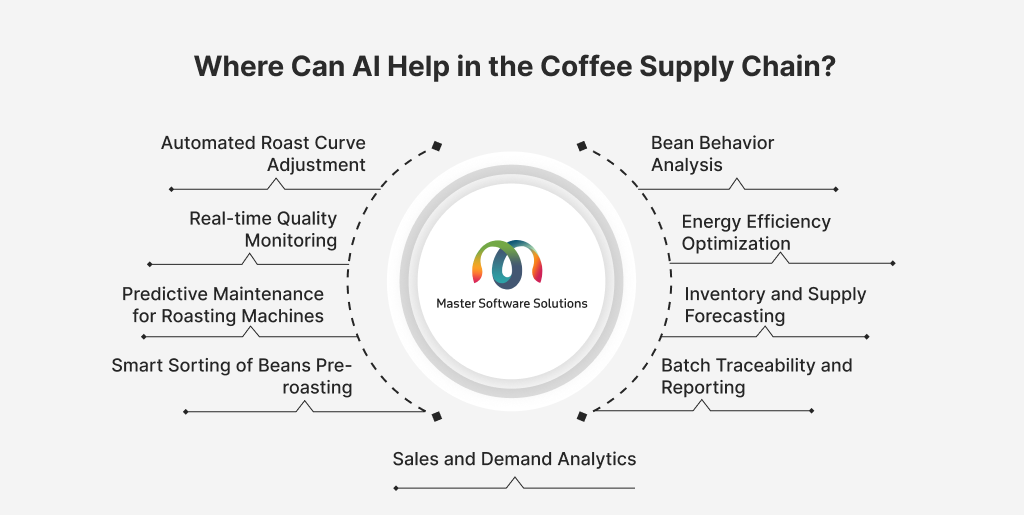

Where can AI help in the coffee supply chain?

The coffee supply chain is complex, stretching from farms and sourcing partners to roasting facilities, distribution networks, and retail shelves. Each stage presents its challenges, including quality fluctuations, unpredictable demand, rising operational costs, and waste risks. Here is how AI adds value at different touchpoints in the coffee supply chain:

Automated roast curve adjustment

AI dynamically adjusts roasting parameters, such as temperature, airflow, and time, based on bean type, moisture level, and real-time sensor data. This ensures every batch follows the optimal roast curve for consistent flavor and aroma.

Bean behavior analysis

AI can analyze historical data on moisture content, density, and origin-specific characteristics to predict how beans will react during roasting. This enables fine-tuning of processes to achieve ideal results, reducing trial-and-error and waste.

Real-time quality monitoring

AI-powered sensors track color, aroma, and temperature throughout the roasting process. Any deviation from the desired profile triggers instant alerts or auto-adjustments, preventing defective batches from reaching packaging and avoiding costly recalls.

Energy efficiency optimization

AI analyzes equipment usage patterns and production schedules to minimize idle times and balance energy consumption. This reduces utility costs while maintaining roasting quality.

Predictive maintenance for roasting machines

AI tracks machine performance metrics, like vibration, heat, or power draw, to predict when maintenance is needed before a breakdown occurs. This minimizes unplanned downtime and protects delivery timelines.

Inventory and supply forecasting

AI forecasts raw material and finished goods requirements by analysing historical data, seasonal trends, and external market factors. This prevents overstocking, which wastes resources, and stockouts, which result in missed sales opportunities.

Smart sorting of beans pre-roasting

Computer vision with AI can identify and remove defective beans before they enter the roaster. This improves quality, reduces waste, and enhances the overall flavor profile.

Batch traceability and reporting

AI-enabled tracking systems log data at every stage, from bean sourcing to packaging, creating a transparent record for compliance, quality assurance, and faster recall management if needed.

Sales and demand analytics

AI integrates sales, marketing, and production data to identify buying trends, evaluate promotions, and predict future demand. This helps coffee business plan production and inventory be more effective, boosting ROI.

Types of AI agents for the coffee industry

AI agents are more than just advanced software. They act as intelligent assistants that can learn, adapt, and make decisions across different stages of production, distribution, and sales. These agents bring precision and efficiency to processes, from optimizing roast curves and forecasting demand to automating quality checks that were once manual and error-prone. Understanding different types of AI agents and their capabilities, coffee businesses can choose the right mix to improve consistency, reduce waste, lower costs, and enhance customer satisfaction.

AI Roast Optimization Agent

It can learn from previous roast data and bean characteristics to automatically adjust roast time, temperature, and airflow in real-time. This ensures consistent coffee flavor and reduces the chances of batch rejection.

Quality Control Agent

The Quality Control Agent utilizes sensors or vision systems to monitor bean color, surface cracks, and moisture, flagging inconsistencies during or post-roasting. This agent logs quality metrics and alerts for anomalies.

Predictive Maintenance Agent

The Predictive Maintenance Agent can track machine usage, vibration, and thermal data to predict failures or wear in roasters and grinders. It also schedules proactive maintenance to reduce downtime.

Inventory Forecasting Agent

The Inventory Forecasting Agent can analyze demand trends, seasonality, and stock levels to predict needed raw materials (green beans & packaging), reducing waste and ensuring uninterrupted production.

Procurement Optimization Agent

The Procurement Optimization Agent can compare vendor pricing and delivery performance, recommending purchase volumes and delivery performance. It helps secure the best cost-to-value supply chain.

Delivery Planning Agent

The Delivery Planning Agent optimizes delivery routes for roasted bean shipments. It can predict shipping delays or cost fluctuations, improving delivery time and customer satisfaction.

Performance Monitoring Agent

The Performance Monitoring Agent tracks KPIs across roasting, energy usage, and output, identifying inefficiencies and generating reports and insights for decision-makers.

Sales Analytics Agent

The Sales Analytics Agent links sales data with roast batches and customer preferences, identifying high-demand blends and seasonal trends. It also offers production change recommendations to align with demand.

Customer Chatbot Agent

The Customer Chatbot Agent assists customers 24/7 with orders, product details, and FAQs. These chatbots can be implemented throughout your website, mobile app, and social channels. This reduces support workload and improves user experience.

Benefits of integrating AI in your ERP for the coffee industry

The coffee industry relies on precision; every roast, batch, and delivery must be perfectly timed and executed to meet customer expectations. Coffee businesses can combine AI with their ERP platform to transform static data into actionable insights, automate key operations, and predict issues before they happen. This bridges the gap between data management and intelligent decision-making, ensuring higher quality, lower costs, and stronger customer loyalty. Here are the benefits of integrating AI in your ERP for the coffee industry:

Enhancing roasting consistency with AI-controlled profiles to boost flavor scores and repeat Sales

AI in ERP connects roast data with bean characteristics to automatically set and adjust roasting parameters. This consistency ensures that each batch meets desired flavor and aroma profiles, driving repeat purchases and customer loyalty.

Improving quality assurance through AI-powered checks to reduce defects and recalls, improving compliance

AI-driven sensors and vision systems integrated into ERP quality modules detect defects in real-time. This reduces the risk of defective coffee reaching customers, enhances regulatory compliance, and protects brand reputation.

Cutting operational costs & minimizing downtime by optimizing energy with AI-guided machine learning scheduling

AI can analyze production schedules and machine performance to run equipment only when needed and at optimal efficiency. This lowers energy costs, reduces idle time, and extends machine lifespan.

Boosting forecast accuracy with AI to reduce waste and maximize sales conversions

AI predicts demand by analyzing historical sales, seasonal trends, and external data (weather or market shifts). This ensures roasting aligns with actual needs, avoiding overproduction and shortages.

Minimizing batch errors using real-time AI monitoring to improve dispatch accuracy and customer trust

AI tracks roasting and packaging stages in real-time. Any deviations from quality or recipe parameters trigger alerts, preventing flawed products from being shipped.

Achieving optimal roasting outcomes via AI-based bean analysis for higher product quality KPIs

AI can evaluate bean density, moisture, and origin data to recommend precise roasting strategies. This improves quality metrics such as flavor score and customer satisfaction index.

Streamlining inventory with AI forecasting to avoid stockouts, delays, and lost revenue

AI can forecast raw material and finished goods needs, syncing procurement, roasting, and dispatch schedules. This minimizes storage costs, prevents delays, and ensures sales opportunities aren’t missed.

Gaining full operational visibility through an AI-integrated ERP for faster decisions and better financial control

AI can pull data from production, quality, sales, and finance into unified dashboards, enabling managers to make quicker, data-backed decisions. This improves agility, profitability, and risk management.

Bottom-line

Artificial Intelligence is a practical, result-driven tool that is transforming coffee business operations, from bean to cup. Incorporating AI into roasting, quality control, supply chain management, and customer engagement, coffee producers can help you achieve unmatched consistency, reduce waste, cut operational costs, and respond to market demands with precision. It empowers businesses to make smarter, faster decisions with real-time insights, strengthening both profitability and customer loyalty.