Subcontracting in manufacturing refers to outsourcing production activities to third-party vendors. Production activities can include manufacturing specific components, the assembly process, or even the entire product line. There are three use cases of subcontracting:

- Basic Subcontracting

- Resupply Subcontracting

- Dropshipping Subcontracting

This blog will discuss Odoo resupply subcontracting in manufacturing for a business that only has a warehouse and no manufacturing or production unit. Such businesses are called warehouse-only businesses.

This blog covers:

What is resupply subcontracting in manufacturing?

Resupply contracting in warehouse-only businesses is specific to the context of an ERP like Odoo ERP, referring to a process where warehouse-only businesses provide their raw material or components to an external contractor or manufacturer. The manufacturer uses this raw material to produce the final product. The core concept of resupply contracting:

Warehouse-only business

The business owns and manages the inventory of raw materials or components. You do not have manufacturing capabilities.

The subcontractor

This is an external company that has the machinery, expertise, and labor to create finished products using your raw materials.

A supplier

The business purchases raw materials or components from its suppliers and stores them in its warehouse.

Why do you need Odoo resupply subcontracting?

Resupply subcontracting is needed for efficient component supply to the subcontractor when they are responsible for manufacturing the final product. This ensures that your subcontractor has sufficient and accurate raw materials to create your final product.

In Odoo, “resupply subcontracting on order” is a route that automatically sends components every time you confirm a purchase order for a product they manufacture. This is needed to streamline the supply of raw materials for subcontracting and ensure that your subcontractor has all the essential components to manufacture the final product. The need for Odoo resupply subcontracting is:

- Removes the need to manually create separate orders for components each time you order a subcontracted product. Odoo automates this process when you confirm the purchase order.

- Automation can reduce manual efforts and errors in supplying components, saving time and resources.

- This ensures that the subcontractor receives components when needed, optimizing production timelines.

- You have complete control over the raw material while the subcontractor manages the manufacturing.

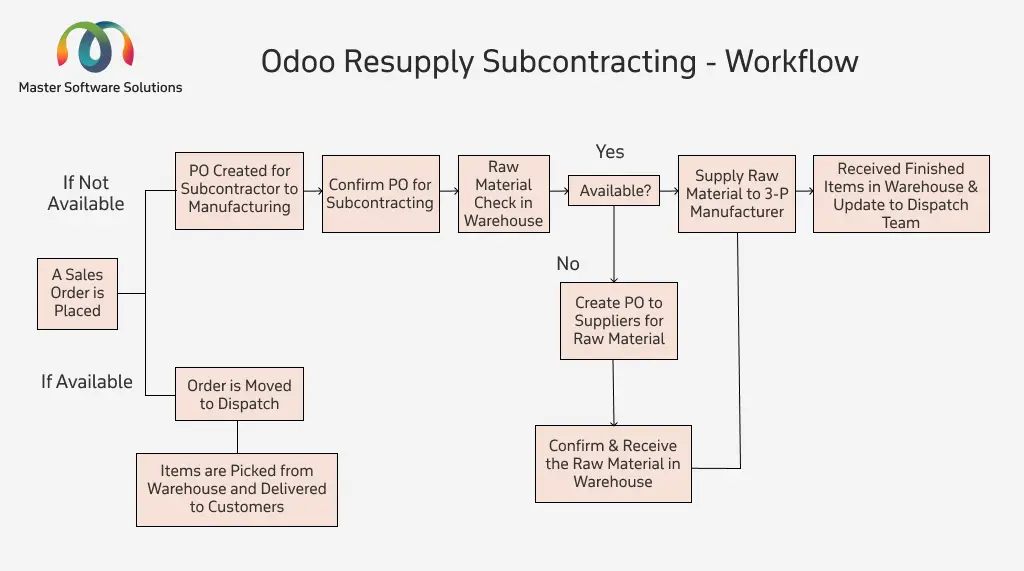

Here, we will explore a specific use case for subcontracting manufacturing, where a business procures raw materials from a vendor and supplies them to a subcontractor for manufacturing. The subcontractor resupplies the final products to the company, which are then delivered to the customers.

Understanding resupply contracting with an example

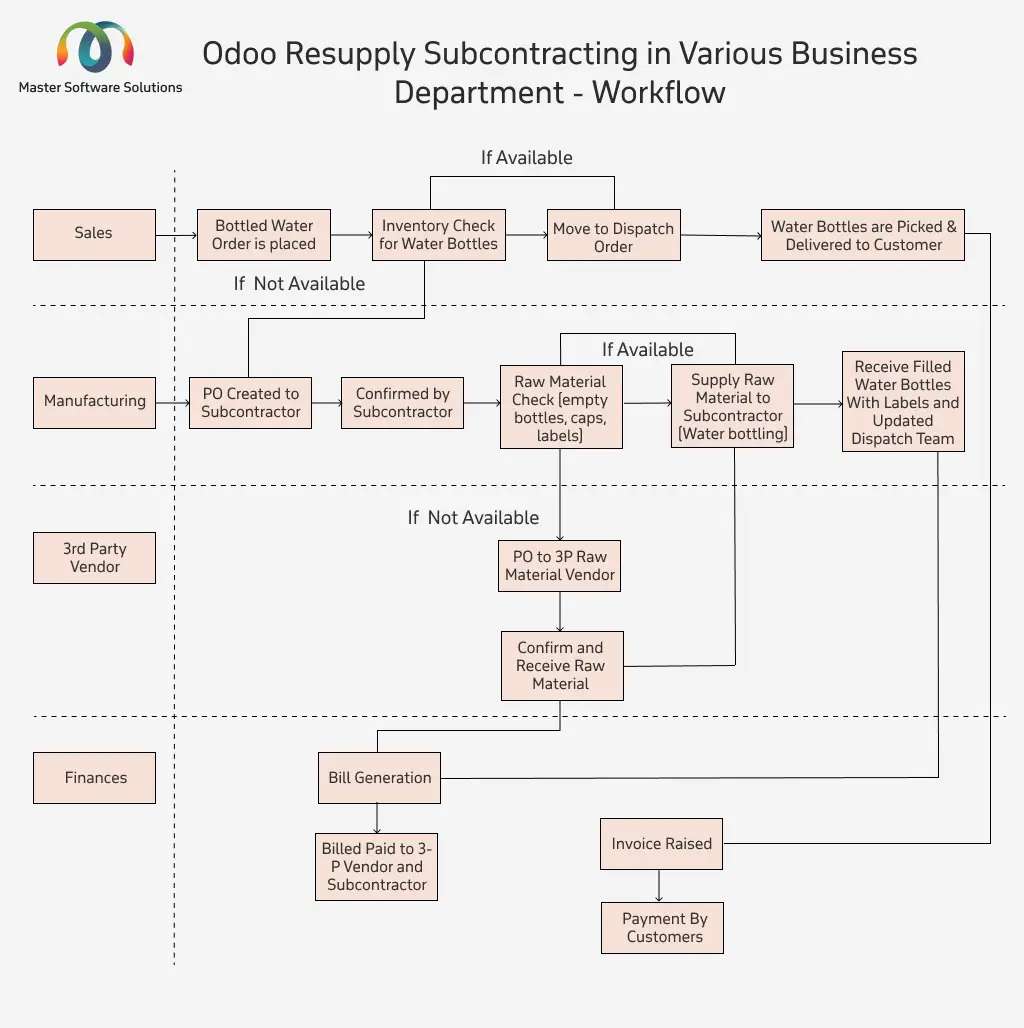

Consider a Bottled Water Business named “Healthy Sip.” It is an online bottled water business that sells bottled water to B2C and B2B customers. They do not own any production line or manufacturing unit. They possess expertise in marketing, managing their online store, deliveries, and customer experience.

Their business challenge

Healthy Sip procures raw materials, including empty water bottles, caps, and labeling material, from a vendor, Super Plasto. This business doesn’t have production lines for filling, capping, and labeling the water bottles. So they outsource the production to Jason Water Filling Station.

Resupply subcontracting action

Here we’ll see how “Healthy Sip” operates.

Procuring raw material from Super Plasto

- Healthy Sip sources quality empty plastic bottles in multiple pack sizes from one vendor.

- Get plastic caps to close and seal the water bottles.

- Produces brand-specific, customised labels that are applied to the bottle after it has been filled with water and sealed with caps.

- Healthy Sip receives and stores these raw materials procured from multiple vendors.

Resupply the raw material order to the Jason Water Filling Station for production.

Jason Water Filling Station receives an order for 100 water bottles, for which Healthy Sip delivers raw materials.

They use Odoo to create a resupply order, initiating the transfer of 100 empty water bottles, 100 caps, and 100 labels. They deliver the material from their warehouse to the Jason Water Filling Station’s production facility. These components are tracked as being at the “JasonWater Filling Station.”

The Jason Water Filling Station receives empty bottles, caps, and labeling material from “Healthy Sip.”

- Their team fills the bottles with water, caps are fitted, and labeling is done.

- The bottles are packed in batches that are to be delivered to Healthy Sip.

- They carefully and thoroughly check the quality of the water before delivering it.

The Jason Filling Station charges Healthy Sip for water, capping, and labeling the bottles. Once these water bottles are ready, either Jason Filling Station delivers them to Healthy Sip or vice versa.

Once the Healthy Sip receives the ordered production products, they check for any breakage or quality issues. They update the main inventory, and individual raw material components are marked as consumed.

Sales and distribution

From Healthy Sip’s warehouse, the water bottles are finally ready to be delivered to the end customers.

How does resupply subcontracting work in Odoo?

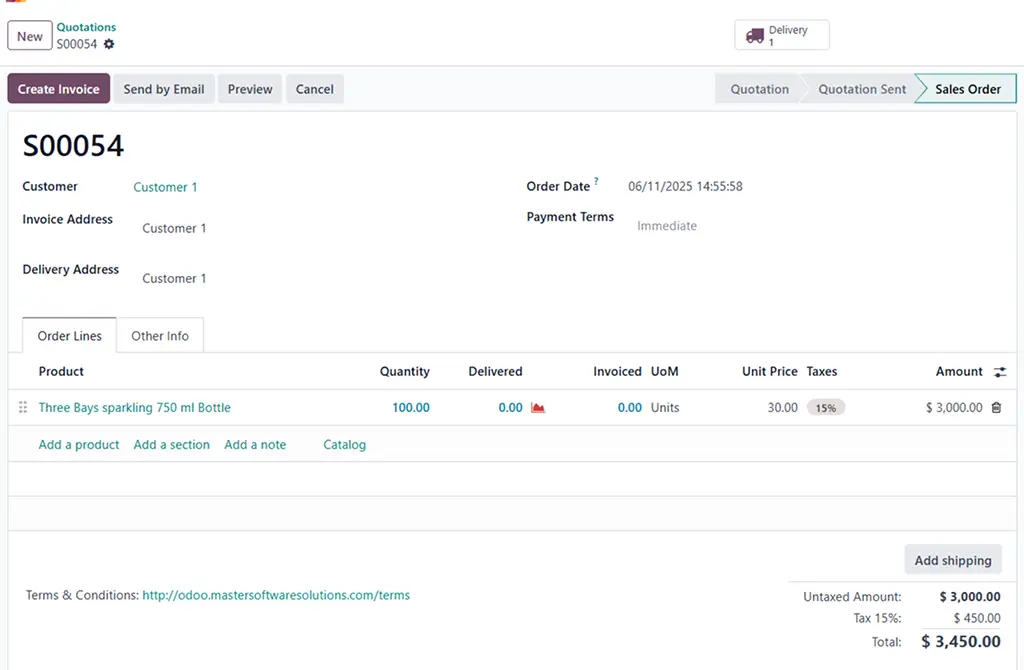

The customer places an order for 100 water bottles. The order can be received from any channel (online or on-call).

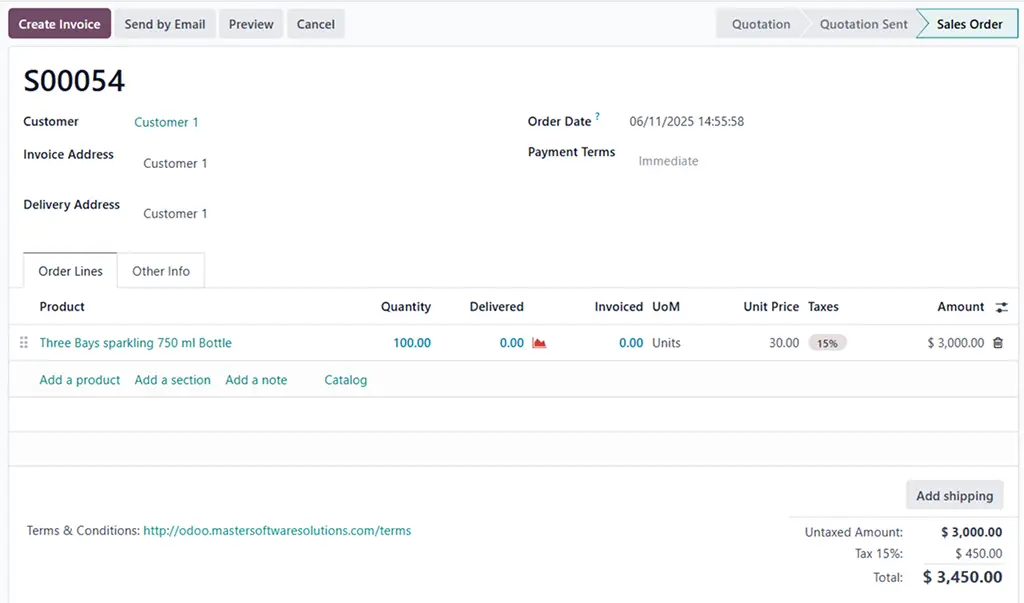

Step 1: Healthy Sip receives a sales order for 100 Water bottles. He creates this sales order in Odoo.

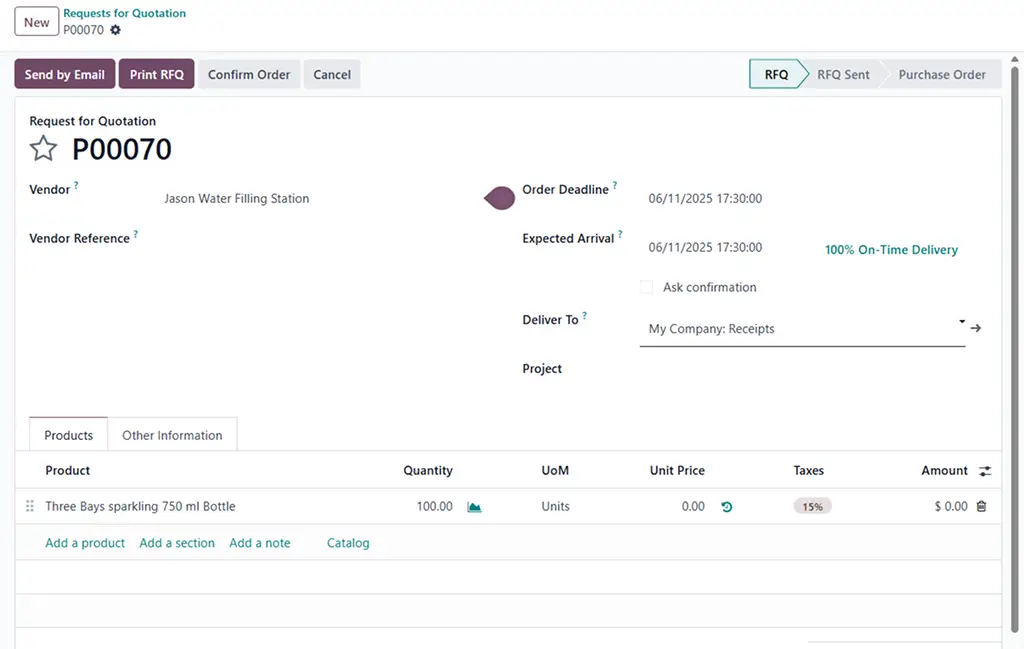

Step 2: When the order is created, an automated RFQ (Request for Quotation) is sent to Jason Water Filling Station (subcontractor/manufacturer).

When Jason confirms the order, the system checks whether Healthy Sip has the required raw material inventory.

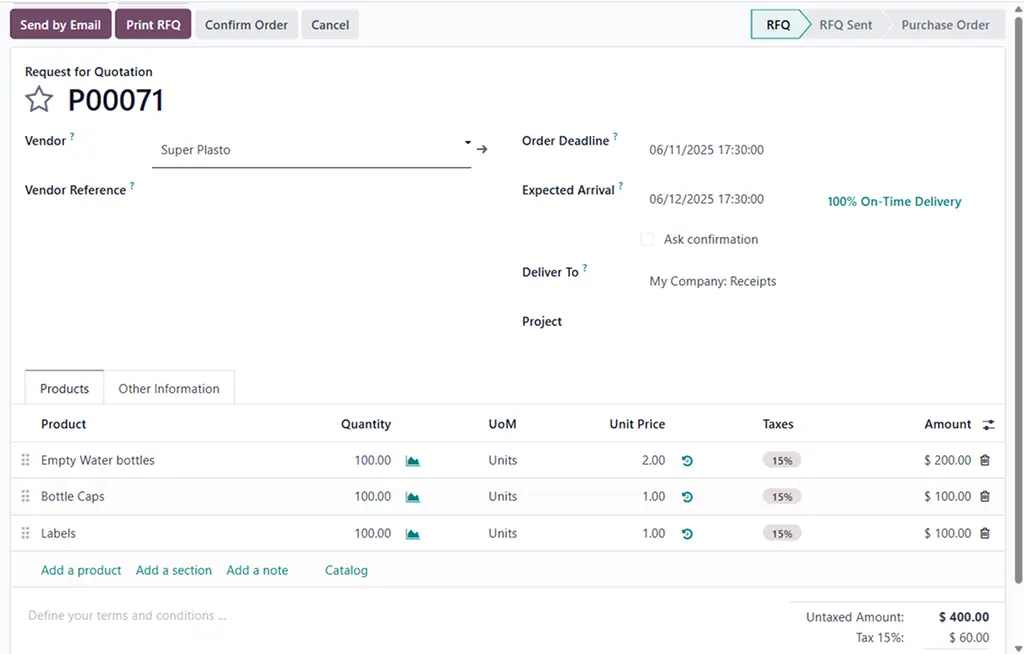

Step 3: If not, an automated RFQ for the raw materials to be used in producing 100 water bottles is sent to Super Plasto for procurement.

In this case, the raw materials for producing 100 water bottles include 100 empty water bottles, 100 caps, and 100 labels.

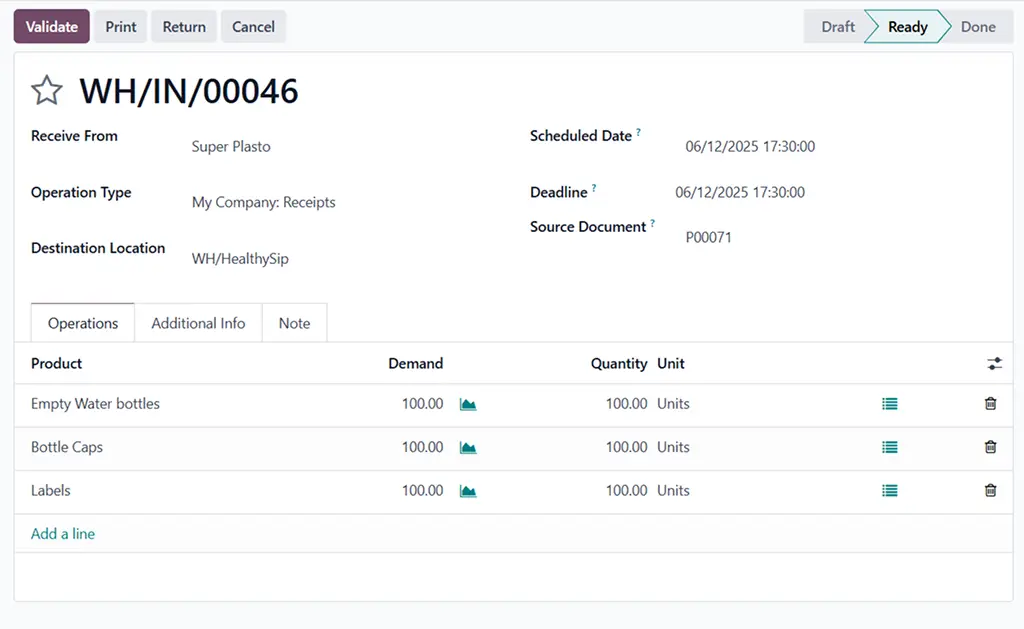

Step 4: Super Plasto sends the requested raw material to Healthy Sip. The Healthy Sip receives and validates items.

Now, Healthy Sip has the raw material to produce final products. They send this raw material to Jason Water Filling Station, their subcontractor for final product production.

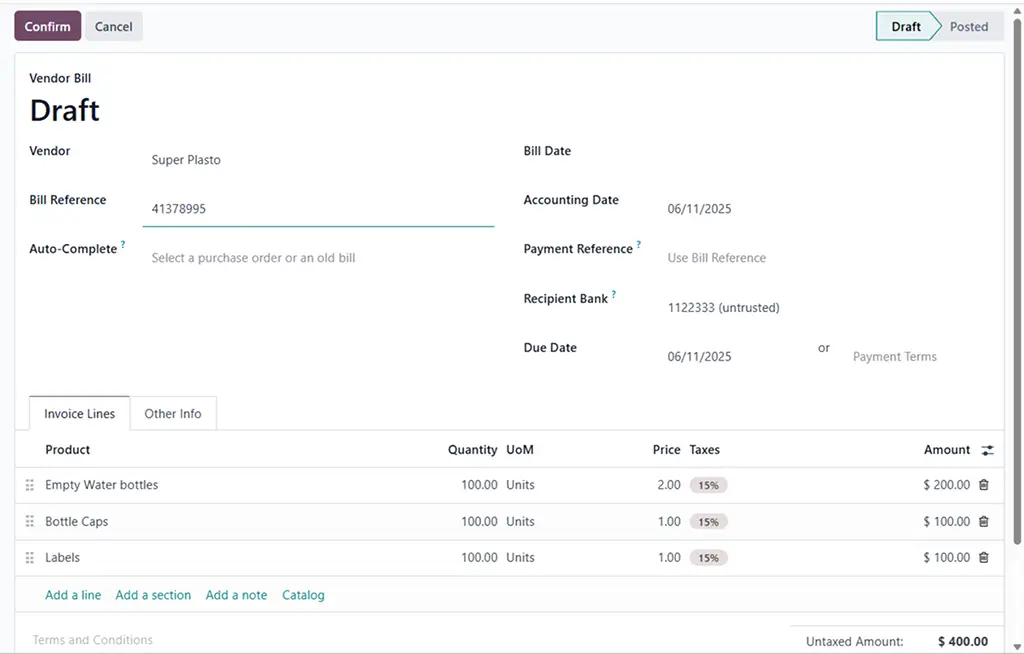

You can either create or upload the bill for Super Plasto on the system.

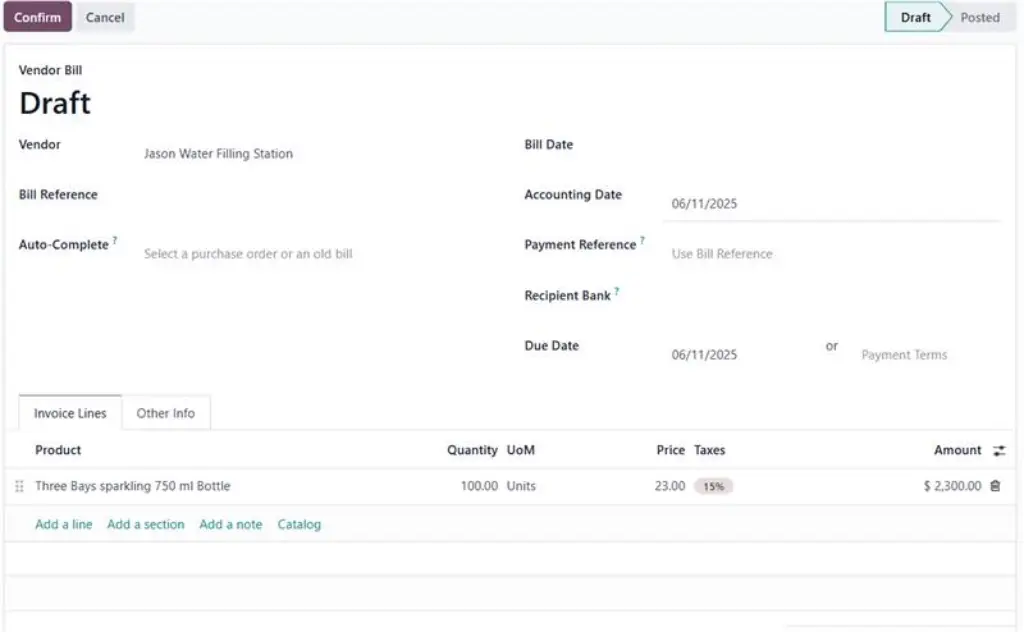

Step 5: Click “Create Bill” to generate the bill.

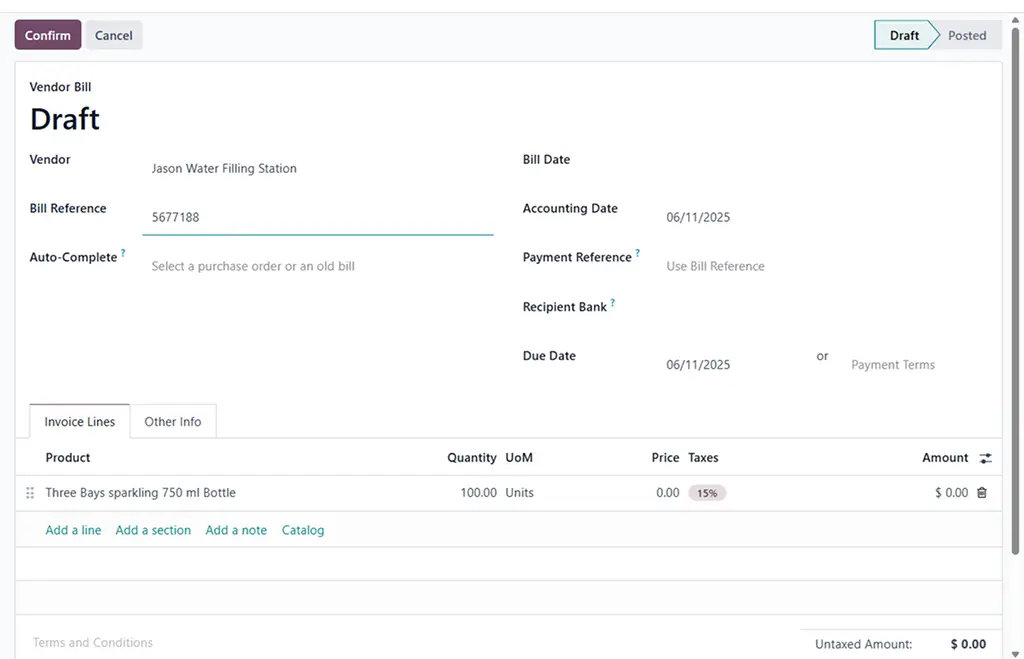

Step 6: Add the “Bill Reference” number.

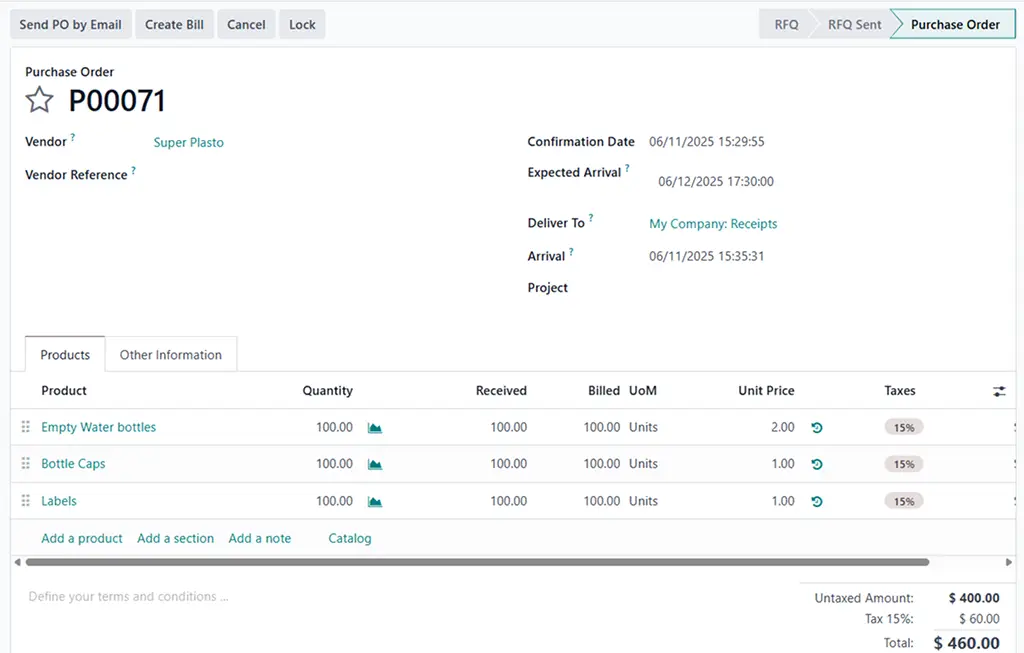

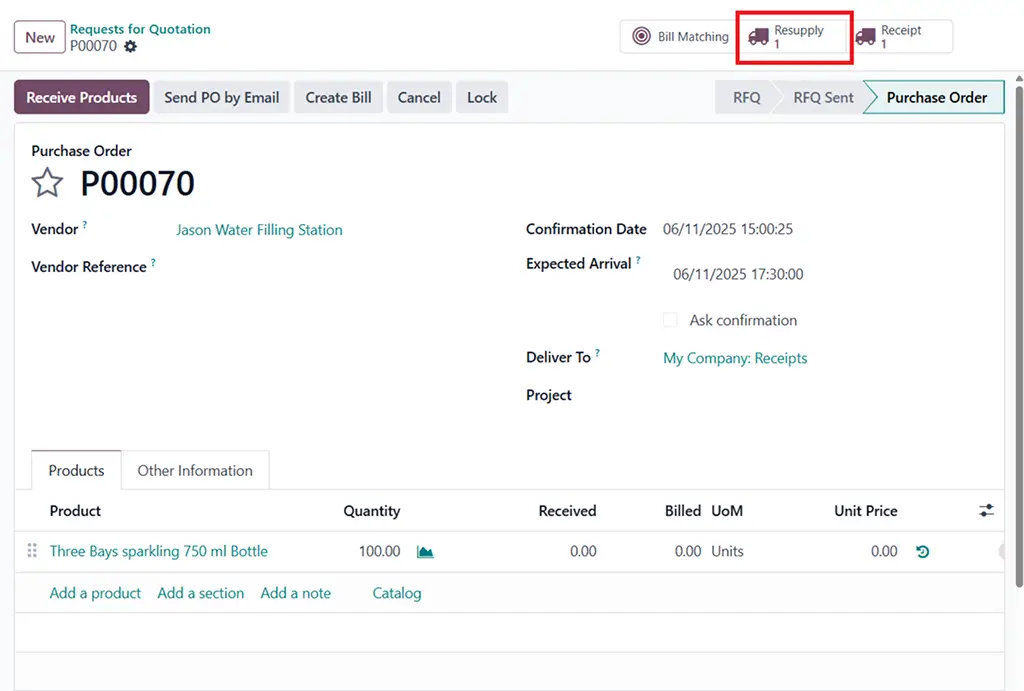

Step 7: Navigate to the “Purchase Order” page for Jason Water Filling Station.

Now, you can transfer the received raw material from the “Healthy Sip warehouse to Jason’s Warehouse.

Step 8: Click on the “Resupply” button to send the received raw material to Jason’s Water Filling Station to produce 100 water bottles.

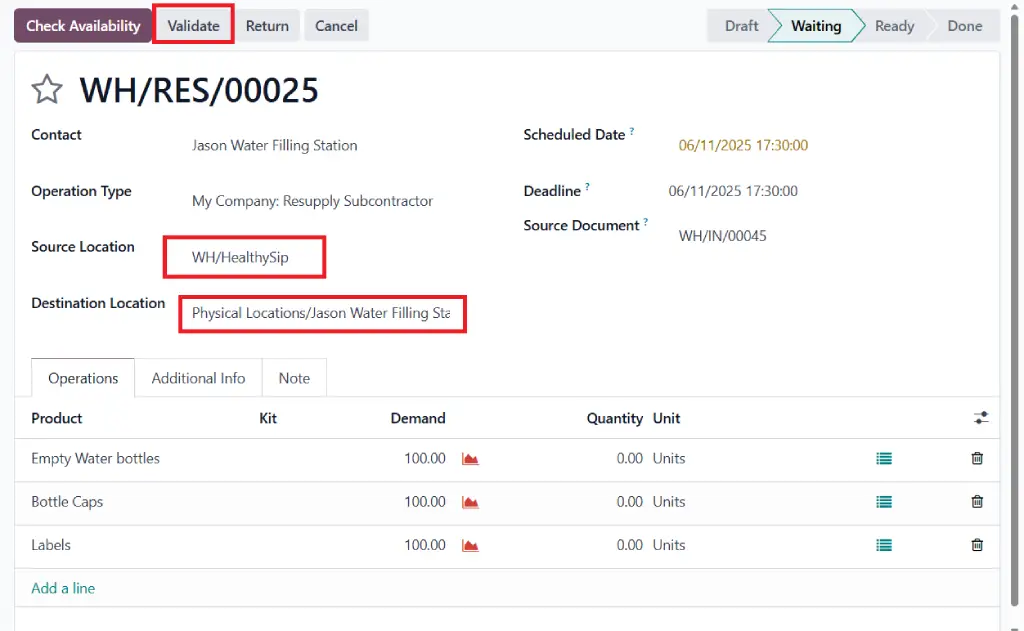

Now, validate that you sent raw material inventory to the Jason Water Filling Station to produce 100 water bottles.

Step 9: Click on the “Validate” button.

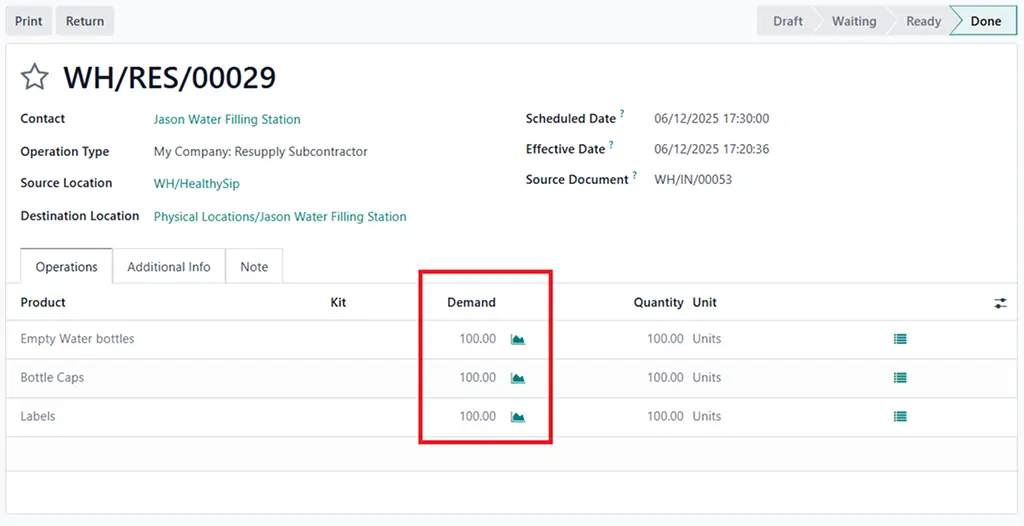

After validating, the demand quantity marked red will turn green.

Now, Jason Water Filling Station produces the order and sends it to Healthy Sip for order fulfillment.

Healthy Sip receives the final product back from Jason Water Filling Station.

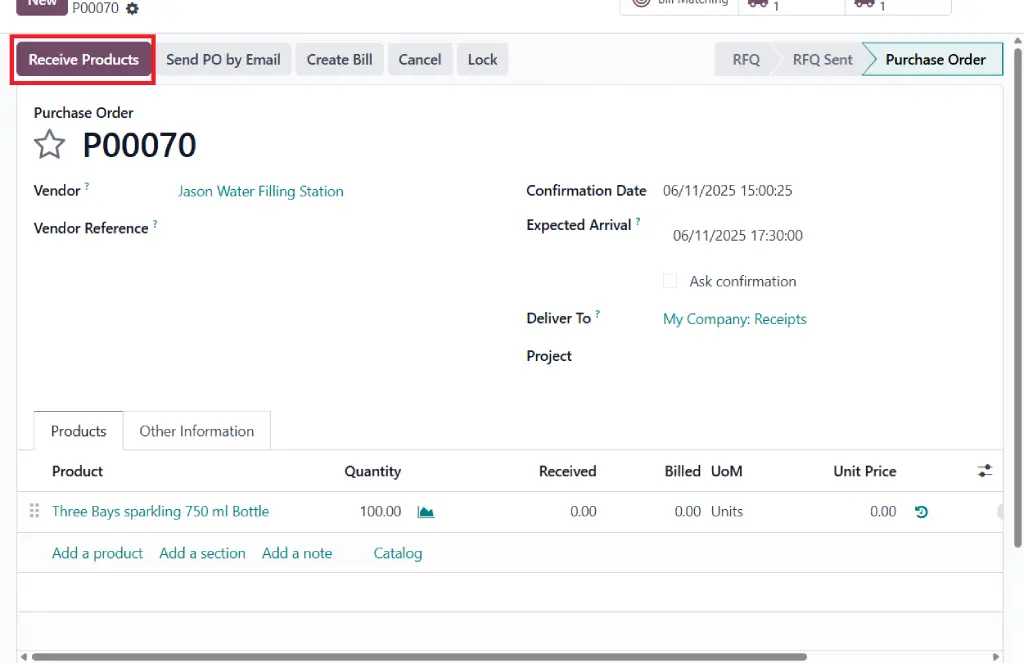

Step 10: Click on the “Receive Product” Button

You can either create or upload the bill Jason Water Filling Station created on the system.

Step 11: Add “Bill Reference”

Now, Healthy Sip has sufficient inventory in its warehouse and can deliver the product to its customers.

Conclusion

Resupply subcontracting is crucial for warehouse-only businesses without production facilities. This business model has become popular in the modern market landscape. To cater to their needs, Odoo provides resupply subcontracting functionality, enabling businesses to manage their operations effectively. It can streamline subcontracting processes, drive operational efficiency, and promote sustainable growth. Master Software Solutions offers one-stop Odoo consulting services, which include implementation, migration from legacy systems, customizations, module development, and ongoing support & maintenance. Schedule a call to discuss your requirements.